| Renewable energy |

|---|

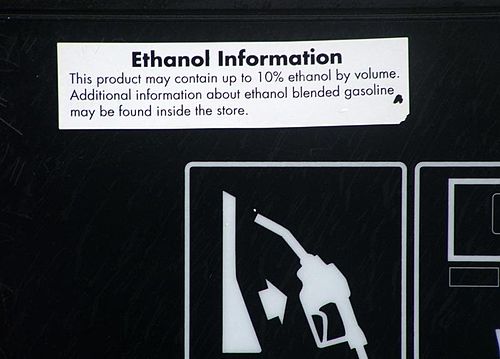

Bioethanol is an alcohol made by fermentation, mostly from carbohydrates produced in sugar or starch crops such as corn, sugarcane, or sweet sorghum. Cellulosic biomass, derived from non-food sources, such as trees and grasses, is also being developed as a feedstock for ethanol production. Ethanol can be used as a fuel for vehicles in its pure form, but it is usually used as a gasoline additive to increase octane and improve vehicle emissions. Bioethanol is widely used in the USA and in Brazil. Current plant design does not provide for converting the lignin portion of plant raw materials to fuel components by fermentation.

Biodiesel can be used as a fuel for vehicles in its pure form, but it is usually used as a diesel additive to reduce levels of particulates, carbon monoxide, and hydrocarbons from diesel-powered vehicles. Biodiesel is produced from oils or fats using transesterification and is the most common biofuel in Europe.

In 2010, worldwide biofuel production reached 105 billion liters (28 billion gallons US), up 17% from 2009,[1] and biofuels provided 2.7% of the world's fuels for road transport, a contribution largely made up of ethanol and biodiesel.[citation needed] Global ethanol fuel production reached 86 billion liters (23 billion gallons US) in 2010, with the United States and Brazil as the world's top producers, accounting together for 90% of global production. The world's largest biodiesel producer is the European Union, accounting for 53% of all biodiesel production in 2010.[1] As of 2011, mandates for blending biofuels exist in 31 countries at the national level and in 29 states or provinces.[2] The International Energy Agency has a goal for biofuels to meet more than a quarter of world demand for transportation fuels by 2050 to reduce dependence on petroleum and coal.[3] The production of biofuels also led into a flourishing automotive industry, where by 2010, 79% of all cars produced in Brazil were made with a hybrid fuel system of bioethanol and gasoline.[4]

There are various social, economic, environmental and technical issues relating to biofuels production and use, which have been debated in the popular media and scientific journals. These include: the effect of moderating oil prices, the "food vs fuel" debate, poverty reduction potential, carbon emissions levels, sustainable biofuel production, deforestation and soil erosion, loss of biodiversity, impact on water resources, rural social exclusion and injustice, shantytown migration, rural unskilled unemployment, and nitrous oxide (NO2) emissions.

Contents

Liquid fuels for transportation

Most transportation fuels are liquids, because vehicles usually require high energy density. This occurs naturally in liquids and solids. High energy density can also be provided by an internal combustion engine. These engines require clean-burning fuels. The fuels that are easiest to burn cleanly are typically liquids and gases. Thus, liquids meet the requirements of being both energy-dense and clean-burning. In addition, liquids (and gases) can be pumped, which means handling is easily mechanized, and thus less laborious.First-generation biofuels

'First-generation' or conventional biofuels are made from sugar, starch, or vegetable oil.Ethanol

Main article: Ethanol fuel

Ethanol fuel is the most common biofuel worldwide, particularly in Brazil. Alcohol fuels are produced by fermentation of sugars derived from wheat, corn, sugar beets, sugar cane, molasses and any sugar or starch from which alcoholic beverages such as whiskey, can be made (such as potato and fruit waste, etc.). The ethanol production methods used are enzyme digestion (to release sugars from stored starches), fermentation of the sugars, distillation and drying. The distillation process requires significant energy input for heat (sometimes unsustainable natural gas fossil fuel, but cellulosic biomass such as bagasse, the waste left after sugar cane is pressed to extract its juice, is the most common fuel in Brazil, while pellets, wood chips and also waste heat are more common in Europe Waste steam fuels ethanol factory- where waste heat from the factories also is used in the district heating grid.

Ethanol can be used in petrol engines as a replacement for gasoline; it can be mixed with gasoline to any percentage. Most existing car petrol engines can run on blends of up to 15% bioethanol with petroleum/gasoline. Ethanol has a smaller energy density than that of gasoline; this means it takes more fuel (volume and mass) to produce the same amount of work. An advantage of ethanol (CH

3CH

2OH) is that it has a higher octane rating than ethanol-free gasoline available at roadside gas stations, which allows an increase of an engine's compression ratio for increased thermal efficiency. In high-altitude (thin air) locations, some states mandate a mix of gasoline and ethanol as a winter oxidizer to reduce atmospheric pollution emissions.

Ethanol is also used to fuel bioethanol fireplaces. As they do not require a chimney and are "flueless", bioethanol fires[5] are extremely useful for newly built homes and apartments without a flue. The downsides to these fireplaces is that their heat output is slightly less than electric heat or gas fires, and precautions must be taken to avoid carbon monoxide poisoning.

In the current corn-to-ethanol production model in the United States, considering the total energy consumed by farm equipment, cultivation, planting, fertilizers, pesticides, herbicides, and fungicides made from petroleum, irrigation systems, harvesting, transport of feedstock to processing plants, fermentation, distillation, drying, transport to fuel terminals and retail pumps, the net energy content value added and delivered to consumers is about 1.3 - 2 times higher than the total energy input. The net climate benefit (all things considered) was in the early 2000s between 15 and 30% net savings,[6] but have since improved and is now approaching the European wheat and corn-based ethanol with typical values of 65-67 % reduction of climate gasses. The best European production lines are however reducing climate emissions with 90-95 %.[7]

Corn-to-ethanol and other food stocks has led to the development of cellulosic ethanol. According to a joint research agenda conducted through the US Department of Energy,[8] the fossil energy ratios (FER) for cellulosic ethanol, corn ethanol, and gasoline are 10.3, 1.36, and 0.81, respectively.[9][10][11]

Ethanol has roughly one-third lower energy content per unit of volume compared to gasoline. This is partly counteracted by the better efficiency when using ethanol (in a long-term test of more than 2,1 million km, the BEST project found FFV vehicles to be 1-26 % more energy efficient than petrol cars The BEST project), but the volumetric consumption increases by approximately 30%, so more fuel stops are required. For practical terms this has no big implications as the typical driver does not use up a full tank in one trip. (E.g. European citizens drive on average less than 20 km/day).

With current subsidies, ethanol fuel is slightly cheaper per distance traveled in the United States.[12]

Biodiesel

Main articles: Biodiesel and Biodiesel around the world

Biodiesel can be used in any diesel engine when mixed with mineral diesel. In some countries, manufacturers cover their diesel engines under warranty for B100 use, although Volkswagen of Germany, for example, asks drivers to check by telephone with the VW environmental services department before switching to B100. B100 may become more viscous at lower temperatures, depending on the feedstock used. In most cases, biodiesel is compatible with diesel engines from 1994 onwards, which use 'Viton' (by DuPont) synthetic rubber in their mechanical fuel injection systems. Note however, that no vehicles are certified for using neat biodiesel before 2014, as there was no emission control protocol available for biodiesel before this date.

Electronically controlled 'common rail' and 'unit injector' type systems from the late 1990s onwards may only use biodiesel blended with conventional diesel fuel. These engines have finely metered and atomized multiple-stage injection systems that are very sensitive to the viscosity of the fuel. Many current-generation diesel engines are made so that they can run on B100 without altering the engine itself, although this depends on the fuel rail design. Since biodiesel is an effective solvent and cleans residues deposited by mineral diesel, engine filters may need to be replaced more often, as the biofuel dissolves old deposits in the fuel tank and pipes. It also effectively cleans the engine combustion chamber of carbon deposits, helping to maintain efficiency. In many European countries, a 5% biodiesel blend is widely used and is available at thousands of gas stations.[13][14] Biodiesel is also an oxygenated fuel, meaning it contains a reduced amount of carbon and higher hydrogen and oxygen content than fossil diesel. This improves the combustion of biodiesel and reduces the particulate emissions from unburnt carbon. However, using neat biodiesel may increase NOx-emissions Nylund.N-O & Koponen.K. 2013. Fuel and Technology Alternatives for Buses. Overall Energy Efficiency and Emission Performance. IEA Bioenergy Task 46. Possibly the new emission standards Euro VI/EPA 10 will lead to reduced NOx-levels also when using B100.

Biodiesel is also safe to handle and transport because it is non-toxic and biodegradable, and has a high flash point of about 300 °F (148 °C) compared to petroleum diesel fuel, which has a flash point of 125 °F (52 °C).[15]

In the USA, more than 80% of commercial trucks and city buses run on diesel. The emerging US biodiesel market is estimated to have grown 200% from 2004 to 2005. "By the end of 2006 biodiesel production was estimated to increase fourfold [from 2004] to more than" 1 billion US gallons (3,800,000 m3).[16]

Other bioalcohols

Methanol is currently produced from natural gas, a nonrenewable fossil fuel. In the future it is hoped to be produced from biomass as biomethanol. This is technically feasible, but the economic viability is still pending[17] The methanol economy is an alternative to the hydrogen economy, compared to today's hydrogen production from natural gas.Butanol (C

4H

9OH) is formed by ABE fermentation (acetone, butanol, ethanol) and experimental modifications of the process show potentially high net energy gains with butanol as the only liquid product. Butanol will produce more energy and allegedly can be burned "straight" in existing gasoline engines (without modification to the engine or car),[18] and is less corrosive and less water-soluble than ethanol, and could be distributed via existing infrastructures. DuPont and BP are working together to help develop butanol. E. coli strains have also been successfully engineered to produce butanol by modifying their amino acid metabolism.[19]

Green diesel

Main article: Vegetable oil refining

Green diesel is produced through hydrocracking biological oil feedstocks, such as vegetable oils and animal fats.[20][21]

Hydrocracking is a refinery method that uses elevated temperatures and

pressure in the presence of a catalyst to break down larger molecules, such as those found in vegetable oils, into shorter hydrocarbon chains used in diesel engines.[22] It may also be called renewable diesel, hydrotreated vegetable oil[22] or hydrogen-derived renewable diesel.[21] Green diesel has the same chemical properties as petroleum-based diesel.[22]

It does not require new engines, pipelines or infrastructure to

distribute and use, but has not been produced at a cost that is

competitive with petroleum.[21] Gasoline versions are also being developed.[23] Green diesel is being developed in Louisiana and Singapore by ConocoPhillips, Neste Oil, Valero, Dynamic Fuels, and Honeywell UOP.[21][24] and also by Preem in Gothenburg, Sweden Evolution DieselBiofuel gasoline

In 2013 UK researchers developed a genetically modified strain of Escherichia coli which could transform glucose into biofuel gasoline that does not need to be blended.[25] Later in 2013 UCLA researchers engineered a new metabolic pathway to bypass glycolysis and increase the rate of conversion of sugars into biofuel,[26] while KAIST researchers developed a strain capable of producing short-chain alkanes, free fatty acids, fatty esters and fatty alcohols through the fatty acyl (acyl carrier protein (ACP)) to fatty acid to fatty acyl-CoA pathway in vivo.[27] It is believed that in the future it will be possible to "tweak" the genes to make gasoline from straw or animal manure.Vegetable oil

Walmart's truck fleet logs millions of miles each year, and the company planned to double the fleet's efficiency between 2005 and 2015.[28] This truck is one of 15 based at Walmart's Buckeye, Arizona

distribution center that was converted to run on a biofuel made from

reclaimed cooking grease produced during food preparation at Walmart

stores.[29]

Main article: Vegetable oil used as fuel

Straight unmodified edible

vegetable oil is generally not used as fuel, but lower-quality oil can

and has been used for this purpose. Used vegetable oil is increasingly

being processed into biodiesel, or (more rarely) cleaned of water and

particulates and used as a fuel.As with 100% biodiesel (B100), to ensure the fuel injectors atomize the vegetable oil in the correct pattern for efficient combustion, vegetable oil fuel must be heated to reduce its viscosity to that of diesel, either by electric coils or heat exchangers. This is easier in warm or temperate climates. Big corporations like MAN B&W Diesel, Wärtsilä, and Deutz AG, as well as a number of smaller companies, such as Elsbett, offer engines that are compatible with straight vegetable oil, without the need for after-market modifications.

Vegetable oil can also be used in many older diesel engines that do not use common rail or unit injection electronic diesel injection systems. Due to the design of the combustion chambers in indirect injection engines, these are the best engines for use with vegetable oil. This system allows the relatively larger oil molecules more time to burn. Some older engines, especially Mercedes, are driven experimentally by enthusiasts without any conversion, a handful of drivers have experienced limited success with earlier pre-"Pumpe Duse" VW TDI engines and other similar engines with direct injection. Several companies, such as Elsbett or Wolf, have developed professional conversion kits and successfully installed hundreds of them over the last decades.

Oils and fats can be hydrogenated to give a diesel substitute. The resulting product is a straight-chain hydrocarbon with a high cetane number, low in aromatics and sulfur and does not contain oxygen. Hydrogenated oils can be blended with diesel in all proportions. They have several advantages over biodiesel, including good performance at low temperatures, no storage stability problems and no susceptibility to microbial attack.[30]

Bioethers

Bioethers (also referred to as fuel ethers or oxygenated fuels) are cost-effective compounds that act as octane rating enhancers."Bioethers are produced by the reaction of reactive iso-olefins, such as iso-butylene, with bioethanol."[31] Bioethers are created by wheat or sugar beet.[32] They also enhance engine performance, whilst significantly reducing engine wear and toxic exhaust emissions. Though bioethers are likely to replace petroethers in the UK, it is highly unlikely they will become a fuel in and of itself due to the low energy density.[33] Greatly reducing the amount of ground-level ozone emissions, they contribute to air quality.[34][35]When it comes to transportation fuel there are six ether additives- 1. Dimethyl Ether (DME) 2. Diethyl Ether (DEE) 3. Methyl Teritiary-Butyl Ether (MTBE) 4. Ethyl ter-butyl ether (ETBE) 5. Ter-amyl methyl ether (TAME) 6. Ter-amyl ethyl Ether (TAEE)[36]

The European Fuel Oxygenates Association (aka EFOA) credits Methyl Tertiary-Butyl Ether (MTBE) and Ethyl ter-butyl ether (ETBE) as the most commonly used ethers in fuel to replace lead. Ethers were brought into fuels in Europe in the 1970s to replace the highly toxic compound.[37] Although Europeans still use Bio-ether additives, the US no longer has an oxygenate requirement therefore bio-ethers are no longer used as the main fuel additive.[38]

Biogas

Main article: Biogas

- Biogas can be recovered from mechanical biological treatment waste processing systems.

- Note: Landfill gas, a less clean form of biogas, is produced in landfills through naturally occurring anaerobic digestion. If it escapes into the atmosphere, it is a potential greenhouse gas.

Syngas

Main article: Gasification

Syngas, a mixture of carbon monoxide, hydrogen and other hydrocarbons, is produced by partial combustion of biomass, that is, combustion with an amount of oxygen that is not sufficient to convert the biomass completely to carbon dioxide and water.[30] Before partial combustion, the biomass is dried, and sometimes pyrolysed.

The resulting gas mixture, syngas, is more efficient than direct

combustion of the original biofuel; more of the energy contained in the

fuel is extracted.- Syngas may be burned directly in internal combustion engines, turbines or high-temperature fuel cells.[41] The wood gas generator, a wood-fueled gasification reactor, can be connected to an internal combustion engine.

- Syngas can be used to produce methanol, DME and hydrogen, or converted via the Fischer-Tropsch process to produce a diesel substitute, or a mixture of alcohols that can be blended into gasoline. Gasification normally relies on temperatures greater than 700 °C.

- Lower-temperature gasification is desirable when co-producing biochar, but results in syngas polluted with tar.

Solid biofuels

Examples include wood, sawdust, grass trimmings, domestic refuse, charcoal, agricultural waste, nonfood energy crops, and dried manure.When raw biomass is already in a suitable form (such as firewood), it can burn directly in a stove or furnace to provide heat or raise steam. When raw biomass is in an inconvenient form (such as sawdust, wood chips, grass, urban waste wood, agricultural residues), the typical process is to densify the biomass. This process includes grinding the raw biomass to an appropriate particulate size (known as hogfuel), which, depending on the densification type, can be from 1 to 3 cm (0 to 1 in), which is then concentrated into a fuel product. The current processes produce wood pellets, cubes, or pucks. The pellet process is most common in Europe, and is typically a pure wood product. The other types of densification are larger in size compared to a pellet, and are compatible with a broad range of input feedstocks. The resulting densified fuel is easier to transport and feed into thermal generation systems, such as boilers.

Industry has used sawdust, bark and chips for fuel for decades, primary in the pulp and paper industry, and also bagasse (spent sugar cane) fueled boilers in the sugar cane industry. Boilers in the range of 500,000 lb/hr of steam, and larger, are in routine operation, using grate, spreader stoker, suspension burning and fluid bed combustion. Utilities generate power, typically in the range of 5 to 50 MW, using locally available fuel. Other industries have also installed wood waste fueled boilers and dryers in areas with low cost fuel.[42]

One of the advantages of biomass fuel is that it is often a byproduct, residue or waste-product of other processes, such as farming, animal husbandry and forestry.[43] In theory, this means fuel and food production do not compete for resources, although this is not always the case.[43]

A problem with the combustion of raw biomass is that it emits considerable amounts of pollutants, such as particulates and polycyclic aromatic hydrocarbons. Even modern pellet boilers generate much more pollutants than oil or natural gas boilers. Pellets made from agricultural residues are usually worse than wood pellets, producing much larger emissions of dioxins and chlorophenols.[44]

In spite of the above noted study, numerous studies have shown biomass fuels have significantly less impact on the environment than fossil based fuels. Of note is the US Department of Energy Laboratory, operated by Midwest Research Institute Biomass Power and Conventional Fossil Systems with and without CO2 Sequestration – Comparing the Energy Balance, Greenhouse Gas Emissions and Economics Study. Power generation emits significant amounts of greenhouse gases (GHGs), mainly carbon dioxide (CO

2). Sequestering CO

2 from the power plant flue gas can significantly reduce the GHGs from the power plant itself, but this is not the total picture. CO

2 capture and sequestration consumes additional energy, thus lowering the plant's fuel-to-electricity efficiency. To compensate for this, more fossil fuel must be procured and consumed to make up for lost capacity.

Taking this into consideration, the global warming potential (GWP), which is a combination of CO

2, methane (CH4), and nitrous oxide (N2O) emissions, and energy balance of the system need to be examined using a life cycle assessment. This takes into account the upstream processes which remain constant after CO

2 sequestration, as well as the steps required for additional power generation. Firing biomass instead of coal led to a 148% reduction in GWP.

A derivative of solid biofuel is biochar, which is produced by biomass pyrolysis. Biochar made from agricultural waste can substitute for wood charcoal. As wood stock becomes scarce, this alternative is gaining ground. In eastern Democratic Republic of Congo, for example, biomass briquettes are being marketed as an alternative to charcoal to protect Virunga National Park from deforestation associated with charcoal production.[45]

Second-generation (advanced) biofuels

Main article: Second-generation biofuels

Second generation biofuels, also known as advanced biofuels, are fuels that can be manufactured from various types of biomass. Biomass is a wide-ranging term meaning any source of organic carbon that is renewed rapidly as part of the carbon cycle. Biomass is derived from plant materials but can also include animal materials.First generation biofuels are made from the sugars and vegetable oils found in arable crops, which can be easily extracted using conventional technology. In comparison, second generation biofuels are made from lignocellulosic biomass or woody crops, agricultural residues or waste, which makes it harder to extract the required fuel.

Sustainable biofuels

Biofuels in the form of liquid fuels derived from plant materials, are entering the market, driven mainly by the need to reduce climate gas emissions, but also by factors such as oil price spikes and the need for increased energy security. However, many of the biofuels that are currently being supplied have been criticised for their adverse impacts on the natural environment, food security, and land use.[46][47]The challenge is to support biofuel development, including the development of new cellulosic technologies, with responsible policies and economic instruments to help ensure that biofuel commercialization is sustainable. Responsible commercialization of biofuels represents an opportunity to enhance sustainable economic prospects in Africa, Latin America and Asia.[46][47][48]

Biofuels by region

Main article: Biofuels by region

See also: Biodiesel around the world

There are international organizations such as IEA Bioenergy,[49] established in 1978 by the OECD International Energy Agency

(IEA), with the aim of improving cooperation and information exchange

between countries that have national programs in bioenergy research,

development and deployment. The UN International Biofuels Forum is formed by Brazil, China, India, Pakistan, South Africa, the United States and the European Commission.[50]

The world leaders in biofuel development and use are Brazil, the United

States, France, Sweden and Germany. Russia also has 22% of world's

forest,[51]

and is a big biomass (solid biofuels) supplier. In 2010, Russian pulp

and paper maker, Vyborgskaya Cellulose, said they would be producing

pellets that can be used in heat and electricity generation from its

plant in Vyborg by the end of the year.[52] The plant will eventually produce about 900,000 tons of pellets per year, making it the largest in the world once operational.Biofuels currently make up 3.1%[53] of the total road transport fuel in the UK or 1,440 million litres. By 2020, 10% of the energy used in UK road and rail transport must come from renewable sources – this is the equivalent of replacing 4.3 million tonnes of fossil oil each year. Conventional biofuels are likely to produce between 3.7 and 6.6% of the energy needed in road and rail transport, while advanced biofuels could meet up to 4.3% of the UK’s renewable transport fuel target by 2020.[54]

Debates regarding the production and use of biofuel

Main article: Issues relating to biofuels

There are various social, economic, environmental and technical

issues with biofuel production and use, which have been discussed in the

popular media and scientific journals. These include: the effect of

moderating oil prices, the "food vs fuel" debate, poverty reduction potential, carbon emissions levels, sustainable biofuel production, deforestation and soil erosion, loss of biodiversity,[55] impact on water resources, the possible modifications necessary to run the engine on biofuel, as well as energy balance and efficiency. The International Resource Panel,

which provides independent scientific assessments and expert advice on a

variety of resource-related themes, assessed the issues relating to

biofuel use in its first report Towards sustainable production and use of resources: Assessing Biofuels.[56]

"Assessing Biofuels" outlined the wider and interrelated factors that

need to be considered when deciding on the relative merits of pursuing

one biofuel over another. It concluded that not all biofuels perform

equally in terms of their impact on climate, energy security and

ecosystems, and suggested that environmental and social impacts need to

be assessed throughout the entire life-cycle.Another issue with biofuel use and production is the US has changed mandates many times because the production has been taking longer than expected. The Renewable Fuel Standard (RFS) set by congress for 2010 was pushed back to at best 2012 to produce 100 million gallons of pure ethanol (not blended with a fossil fuel).[57]

Current research

Research is ongoing into finding more suitable biofuel crops and improving the oil yields of these crops. Using the current yields, vast amounts of land and fresh water would be needed to produce enough oil to completely replace fossil fuel usage. It would require twice the land area of the US to be devoted to soybean production, or two-thirds to be devoted to rapeseed production, to meet current US heating and transportation needs.[citation needed]Specially bred mustard varieties can produce reasonably high oil yields and are very useful in crop rotation with cereals, and have the added benefit that the meal left over after the oil has been pressed out can act as an effective and biodegradable pesticide.[58]

The NFESC, with Santa Barbara-based Biodiesel Industries, is working to develop biofuels technologies for the US navy and military, one of the largest diesel fuel users in the world.[59] A group of Spanish developers working for a company called Ecofasa announced a new biofuel made from trash. The fuel is created from general urban waste which is treated by bacteria to produce fatty acids, which can be used to make biofuels.[60]

Ethanol biofuels

Main articles: Ethanol fuel and Cellulosic ethanol commercialization

As the primary source of biofuels in North America, many organizations are conducting research in the area of ethanol production. The National Corn-to-Ethanol Research Center (NCERC) is a research division of Southern Illinois University Edwardsville dedicated solely to ethanol-based biofuel research projects.[61] On the federal level, the USDA

conducts a large amount of research regarding ethanol production in the

United States. Much of this research is targeted toward the effect of

ethanol production on domestic food markets.[62] A division of the U.S. Department of Energy, the National Renewable Energy Laboratory (NREL), has also conducted various ethanol research projects, mainly in the area of cellulosic ethanol.[63]Cellulosic ethanol commercialization is the process of building an industry out of methods of turning cellulose-containing organic matter into fuel. Companies, such as Iogen, POET, and Abengoa, are building refineries that can process biomass and turn it into bioethanol. Companies, such as Diversa, Novozymes, and Dyadic, are producing enzymes that could enable a cellulosic ethanol future. The shift from food crop feedstocks to waste residues and native grasses offers significant opportunities for a range of players, from farmers to biotechnology firms, and from project developers to investors.[64]

As of 2013, the first commercial-scale plants to produce cellulosic biofuels have begun operating. Multiple pathways for the conversion of different biofuel feedstocks are being used. In the next few years, the cost data of these technologies operating at commercial scale, and their relative performance, will become available. Lessons learnt will lower the costs of the industrial processes involved.[65]

In parts of Asia and Africa where drylands prevail, sweet sorghum is being investigated as a potential source of food, feed and fuel combined. The crop is particularly suitable for growing in arid conditions, as it only extracts one seventh of the water used by sugarcane. In India, and other places, sweet sorghum stalks are used to produce biofuel by squeezing the juice and then fermenting into ethanol.[66]

A study by researchers at the International Crops Research Institute for the Semi-Arid Tropics (ICRISAT) found that growing sweet sorghum instead of grain sorghum could increase farmers incomes by US$40 per hectare per crop because it can provide fuel in addition to food and animal feed. With grain sorghum currently grown on over 11 million hectares (ha) in Asia and on 23.4 million ha in Africa, a switch to sweet sorghum could have a considerable economic impact.[67]

Algae biofuels

Main articles: Algaculture and Algal fuel

From 1978 to 1996, the US NREL experimented with using algae as a biofuels source in the "Aquatic Species Program".[68] A self-published article by Michael Briggs, at the UNH Biofuels Group, offers estimates for the realistic replacement of all vehicular

fuel with biofuels by using algae that have a natural oil content

greater than 50%, which Briggs suggests can be grown on algae ponds at wastewater treatment plants.[69]

This oil-rich algae can then be extracted from the system and processed

into biofuels, with the dried remainder further reprocessed to create

ethanol. The production of algae to harvest oil for biofuels has not yet

been undertaken on a commercial scale, but feasibility studies have been conducted to arrive at the above yield estimate. In addition to its projected high yield, algaculture — unlike crop-based biofuels — does not entail a decrease in food production, since it requires neither farmland nor fresh water.

Many companies are pursuing algae bioreactors for various purposes,

including scaling up biofuels production to commercial levels.[70][71] Prof. Rodrigo E. Teixeira from the University of Alabama in Huntsville demonstrated the extraction of biofuels lipids from wet algae using a simple and economical reaction in ionic liquids.[72]Jatropha

Main article: Jatropha curcas

Several groups in various sectors are conducting research on Jatropha curcas, a poisonous shrub-like tree that produces seeds considered by many to be a viable source of biofuels feedstock oil.[73]

Much of this research focuses on improving the overall per acre oil

yield of Jatropha through advancements in genetics, soil science, and

horticultural practices.SG Biofuels, a San Diego-based jatropha developer, has used molecular breeding and biotechnology to produce elite hybrid seeds that show significant yield improvements over first-generation varieties.[74] SG Biofuels also claims additional benefits have arisen from such strains, including improved flowering synchronicity, higher resistance to pests and diseases, and increased cold-weather tolerance.[75]

Plant Research International, a department of the Wageningen University and Research Centre in the Netherlands, maintains an ongoing Jatropha Evaluation Project that examines the feasibility of large-scale jatropha cultivation through field and laboratory experiments.[76] The Center for Sustainable Energy Farming (CfSEF) is a Los Angeles-based nonprofit research organization dedicated to jatropha research in the areas of plant science, agronomy, and horticulture. Successful exploration of these disciplines is projected to increase jatropha farm production yields by 200-300% in the next 10 years.[77]

Fungi

A group at the Russian Academy of Sciences in Moscow, in a 2008 paper, stated they had isolated large amounts of lipids from single-celled fungi and turned it into biofuels in an economically efficient manner. More research on this fungal species, Cunninghamella japonica, and others, is likely to appear in the near future.[78] The recent discovery of a variant of the fungus Gliocladium roseum points toward the production of so-called myco-diesel from cellulose. This organism was recently discovered in the rainforests of northern Patagonia, and has the unique capability of converting cellulose into medium-length hydrocarbons typically found in diesel fuel.[79]Animal Gut Bacteria

Microbial gastrointestinal flora in a variety of animals have shown potential for the production of biofuels. Recent research has shown that TU-103, a strain of Clostridium bacteria found in Zebra feces, can convert nearly any form of cellulose into butanol fuel.[80] Microbes in panda waste are being investigated for their use in creating biofuels from bamboo and other plant materials.[81]Greenhouse gas emissions

Some scientists have expressed concerns about land-use change in response to greater demand for crops to use for biofuel and the subsequent carbon emissions.[82] The payback period, that is, the time it will take biofuels to pay back the carbon debt they acquire due to land-use change, has been estimated to be between 100 and 1000 years, depending on the specific instance and location of land-use change. However, no-till practices combined with cover-crop practices can reduce the payback period to three years for grassland conversion and 14 years for forest conversion.[83]A study conducted in the Tocantis State, in northern Brazil, found that many families were cutting down forests in order to produce two conglomerates of oilseed plants, the J. curcas (JC group) and the R. communis (RC group). This region is composed of 15% Amazonian rainforest with high biodiversity, and 80% Cerrado forest with lower biodiversity. During the study, the farmers that planted the JC group released over 2193 Mg CO2, while losing 53-105 Mg CO2 sequestration from deforestation; and the RC group farmers released 562 Mg CO2, while losing 48-90 Mg CO2 to be sequestered from forest depletion.[84] The production of these types of biofuels not only led into an increased emission of carbon dioxide, but also to lower efficiency of forests to absorb the gases that these farms were emitting. This has to do with the amount of fossil fuel the production of fuel crops involves. In addition, the intensive use of monocropping agriculture requires large amounts of water irrigation, as well as of fertilizers, herbicides and pesticides. This does not only lead to poisonous chemicals to disperse on water runoff, but also to the emission of nitrous oxide (NO2) as a fertilizer byproduct, which is three hundred times more efficient in producing a greenhouse effect than carbon dioxide (CO2).[85]

Biofuels made from waste biomass or from biomass grown on abandoned agricultural lands incur little to no carbon debt.[86]

No comments:

Post a Comment