From Wikipedia, the free encyclopedia

| Type 60 Self-propelled 106 mm Recoilless Gun | |

|---|---|

Komatsu Type 60 Recoilless Gun during winter exercises

|

|

| Type | Tank destroyer |

| Place of origin | Japan |

| Service history | |

| In service | 1960-2008 |

| Used by | |

| Production history | |

| Designer | Komatsu |

| Designed | 1956-1960 |

| Manufacturer | Komatsu |

| Produced | 1960–77 |

| Number built | 252 |

| Specifications | |

| Weight | 8,000 kilograms (18,000 lb) |

| Length | 4.3 meters (14 ft 1 in) |

| Width | 2.23 meters (7 ft 4 in) |

| Height | 1.38 meters (4 ft 6 in) |

| Crew | 3 |

| Caliber | 105 millimeters (4.1 in) |

| Elevation | -20° to +15° |

| Traverse | 60° |

| Muzzle velocity | 500 m/s |

| Effective range | 2,750 meters (3,010 yd) |

| Maximum range | 7,700 meters (8,400 yd) |

| Armor | 12 millimeters (0.5 in) steel |

Main

armament |

2 × M40 recoilless rifles |

Secondary

armament |

.50 caliber spotting rifle |

| Engine | Komatsu 6T 120-2 air-cooled, 6-cylinder diesel 150 horsepower (110 kW) |

| Power/weight | 15 hp/t |

| Transmission | manual (4 forward and 1 reverse gears) |

| Suspension | torsion bar |

| Ground clearance | 0.35 meters (14 in) |

| Fuel capacity | 140 liters (37 U.S. gal) |

Operational

range |

250 kilometers (160 mi) (road) |

| Speed | 55 kilometers per hour (34 mph) |

Development

In the mid-1950s the Japan Ground Self-Defense Force contracted for one prototype from Komatsu (SS1) and Mitsubishi Heavy Industries (SS2) powered by a 110 hp six-cylinder diesel engine and fitted with two 105-millimeter (4.1 in) recoilless rifles. They were delivered in 1956. A second series of prototypes was built with 4 recoilless rifles, but adoption of the American M40 forced the reversion to two weapons. A third series of three prototypes was built by Komatsu as the SS4 that were heavier with a more powerful engine, a new transmission and clutch and a two-speed auxiliary transmission. They were accepted into service in September 1960.Starting in 1974 a 150 hp Komatsu SA4D105 air-cooled, 4-cylinder diesel engine was fitted.

Operation

The commander is seated to the left of the two weapons and his position is attached to their mounting so that he remains at the same height when they are elevated for firing. The M40s can be fired from the lowered position, but their traverse is limited to 20°, elevation to +10° and depression to -5°. The elevation mechanism is manually operated. The loader is seated to the left of the commander and must exit through his rear-opening hatch to reload the recoilless rifles while on top of the engine deck or behind the vehicle.Only 6 rounds of ammunition are stowed on board.

As of 2001, Japan reported to the United Nations Office for Disarmament Affairs that 140 Type 60s were in service.[1]

Similar vehicles

M50 Ontos

From Wikipedia, the free encyclopedia

| Rifle, Multiple 106 mm, Self-propelled, M50 “Ontos” | |

|---|---|

|

|

| Type | Tank destroyer |

| Place of origin | United States |

| Service history | |

| In service | 1956–69 |

| Used by | United States |

| Wars | Vietnam War Operation Power Pack |

| Production history | |

| Designer | Allis-Chalmers |

| Designed | 1952 |

| Manufacturer | Allis-Chalmers |

| Produced | 1955–57 |

| Number built | 297 |

| Variants | M50A1 |

| Specifications | |

| Crew | 3 (driver, gunner and loader) |

| Caliber | 106 mm |

| Muzzle velocity | 500 m/s |

| Effective firing range | 2,750 m |

| Maximum firing range | 7,700 m |

Main

armament |

6 × M40 recoilless rifles |

Secondary

armament |

1 × .30-caliber machine gun |

| Engine | GM 6-cyl 302 in³ |

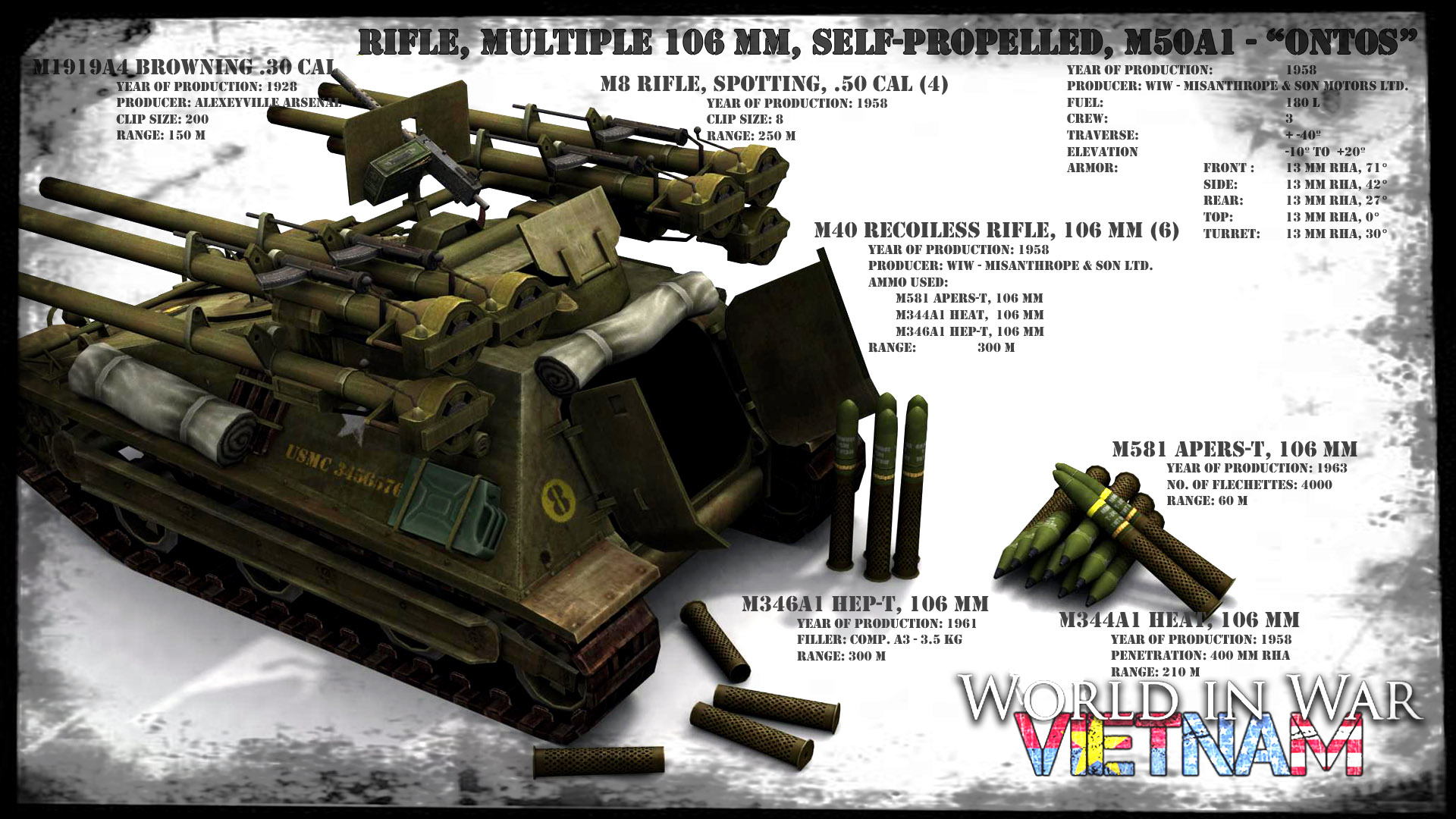

The Ontos, officially the Rifle, Multiple 106 mm, Self-propelled, M50, was an American light armored tracked anti-tank vehicle developed in the 1950s. It mounted six M40 106 mm recoilless rifles as its main armament, which could be fired in rapid succession against single targets to guarantee a kill.

Originally conceived as a fast tank killer, it was employed by US Marines who consistently reported excellent results when used for direct fire support against infantry during the Vietnam War. Its mobility and firepower were proven in numerous battles and operations. Produced in limited numbers and largely expended towards the end of the conflict, the Ontos was removed from service in 1969.

Contents

Development

The Ontos (Greek for "thing" [1]) project was created to be an air transportable tank-destroyer capable of being lifted by the cargo aircraft of the 1950s. This limited it to a weight between 10 and 20 metric tons, the only other limitation to the design being that it had to use the six-cylinder engine then widely used in the army's GMC trucks. Allis-Chalmers was awarded the contract on August 12, 1955, for 297 vehicles.Allis-Chalmers' first vehicle, completed in 1952, was based on the running gear of the M56 Scorpion light anti-tank vehicle. The vehicle mounted a cast steel turret with two arms holding three rifles each. This early model could traverse the turret only about 15 degrees. A second prototype used a new suspension system including new tracks, and a newer turret with about 40 degrees traverse. Only eighteen rounds for the main guns could be carried inside the vehicle due to limited space. Four of the rifles also had .50-caliber spotting rifles attached, firing a round with the same trajectory as the 106 mm round, that gave off a puff of smoke on impact. The spotting rifles were thus used to line up the 106 mm recoilless rifles with the target. A single .30 caliber M1919A4 machine gun was also carried for anti-infantry use.

The vehicle was taken to the Aberdeen testing facility where single rifles had been tested. When all six weapons were fired at once, the back blast from the firing knocked bricks out of a nearby building and knocked the rear windows out of several cars. The prototype and testing stage was completed by 1955, at which point the Army canceled its order. As an anti-tank vehicle the Ontos had several problems, including a small ammunition load, a very high profile for such a small vehicle, and the need for the crew to exit the vehicle in order to reload the guns, exposing them to enemy fire. Although the Army canceled their order, the Marine Corps were desperate for any anti-tank vehicles they could get, and ordered 297. Production ran from 1955 through 1957. The first vehicle accepted by the Marine Corps was on 31 October 1956.

Variants and upgrades

Several variants were also studied. The Utility Vehicle, Tracked, Infantry, T55 was a light APC, but only two versions of the prototype were built. It proved impractical due to the limited room inside, carrying only five infantry and forcing the driver to lie prone. A "stretched" version known as the Utility Vehicle, Tracked, Infantry, T56 was also built, and while it held a complete eight-man team, their equipment had to be carried on the outside. Neither was considered very useful.In 1960 there was a brief study made to replace the Ontos's 106 mm rifles with a new 105 mm design that included a re-loading system similar to that on a revolver. This project was not accepted.

Another proposed upgrade was replacing the GMC engine with a newer Chrysler 361 in³ V8 engine. This upgrade was implemented and the variant was named Rifle, Multiple 106 mm, Self-propelled, M50A1. However of the 297 vehicles initially accepted by the Marines, only 176 were converted between 1963 to 1965 to this standard.

Service

While the M50 was designed as a tank destroyer, the NVA deployed few tanks. It was more widely used for direct fire support for the infantry in combat, a role that was never emphasized in training or doctrine. Like the army's M113, its light armor was effective against small arms but vulnerable to mines and rocket-propelled grenades. Consequently many Ontos were deployed in static defense positions.The Ontos was particularly liked by its crews, and praised by commanders. Their relatively light weight meant that the M50s could also go where tanks got bogged down. The Ontos, with its lower ground pressure, could drag timbers up to the tanks to help get them unstuck. In another operation, the Ontos was the only tracked vehicle light enough to cross a pontoon bridge. In the Battle of Hue, regimental commander Colonel Stanley Hughes felt the Ontos was the most effective of all marine supporting arms. Its mobility made it less vulnerable than tanks, which suffered heavy losses, while at ranges of 300 to 500 yards (270 to 460 m), its recoilless rifles could knock holes in or completely knock down walls. The appearance of an Ontos was sometimes enough to make the enemy break and run, and anecdotal accounts describe the enemy fleeing occupied buildings when an Ontos's spotting round entered a window. In Operation DeSoto, the introduction of the large CH-53 Sea Stallion helicopter made possible moving a platoon 25 miles (40 km) south of Quan Ngai City carrying Ontos in slings underneath the aircraft.[2]

The Ontos units were deactivated in May 1969, and some of the vehicles were handed over to an army light infantry brigade. They used them until they ran out of spare parts, and then removed the turrets and used them as fixed fortifications. Both these and the rest of the vehicles returned from Vietnam in 1970 and were cut up for scrap, with some of the chassis being sold off as construction vehicles.[citation needed]

Preserved vehicles on display

- The Patton Museum of Cavalry & Armor in Fort Knox, Kentucky.

- The Rock Island Arsenal Museum in Rock Island, Illinois.

- Camp Atterbury, Edinburgh, Indiana.

- The American Heritage Park, in El Monte, California.

- The Aberdeen Proving Ground's Museum in Aberdeen, Maryland has a T165E2, the 19th prototype, though it is not currently on display. The vehicle is currently undergoing a cosmetic restoration.

- Mr. Fred Ropkey, owner of the Ropkey Armor Museum in Crawfordsville, Indiana owns the first prototype T165, a later model Ontos, and a parts machine.

- The National Museum of the Marine Corps in Quantico, Virginia has completed the restoration of an M50A1 Ontos.

- The U.S. Marine Corps Museum of the Carolinas in Jacksonville, North Carolina has an operational M50A1 Ontos which is not on public display.

- There is an M50A1 Ontos on outside display at the Navy Facility at China Lake, California. [3]

- The Marine Corps Air Ground Combat Center Twentynine Palms, California has an M50A1 Ontos on outside display.

- The Military Vehicle Technology Foundation in Portola Valley, California has a T165E1 prototype with the original GM 302ci engine which is currently undergoing a complete operational restoration, and a second prototype T165E2 Ontos.

- The U.S. Army Artillery Museum at Ft. Sill, Oklahoma.

See also

- List of artillery

- List of self-propelled anti-tank guns

- List of artillery of the United States

- G-numbers (SNL G288)

Type 60 Self-propelled 106 mm Recoil-less Gun

Jagdpanzer IV

From Wikipedia, the free encyclopedia

| Jagdpanzer IV | |

|---|---|

Jagdpanzer IV at the Deutsches Panzermuseum

|

|

| Type | Tank destroyer |

| Place of origin | Nazi Germany |

| Production history | |

| Produced | December 1943 – April 1945 |

| Number built | about 2,000 |

| Specifications (Jagdpanzer IV/70(V)[1]) | |

| Weight | 25.8 tonnes (28.4 short tons; 25.4 long tons) |

| Length | 8.5 m (27 ft 11 in) |

| Width | 3.17 m (10 ft 5 in) |

| Height | 1.85 m (6 ft 1 in) |

| Crew | 4 |

| Armor | 10–80 mm (0.39–3.15 in) |

Main

armament |

1x 7.5 cm Pak 42 L/70 55 rounds |

Secondary

armament |

1x 7.92 mm Maschinengewehr 34 600 rounds |

| Engine | Maybach HL 120 TRM 300 PS (296 hp, 221 kW) |

| Power/weight | 11.63 PS/tonne |

| Suspension | Leaf springs |

Operational

range |

210 km (130 mi) |

Officially, only the L/48-armed vehicle was named Jagdpanzer IV. The L/70-armed vehicle was named Panzer IV/70. In this article, both versions are referred to in general as Jagdpanzer IV, except in the variants and surviving vehicles section.

Development

After the Battle of Stalingrad, in September 1942 the Wehrmacht's arms bureau, the Waffenamt, called for a new standard for assault weapons: 100 mm of armor to the front, 40–50 mm on the sides, wider tracks, ground clearance of 50 cm, top speed of 26 km/h and the lowest possible firing positions. The new Panzerjager ("tank hunter") design would be armed with the same 7.5 cm gun as fitted to the Panther: the Pak 42 L/70. Initially a new chassis was planned, but that of the Panzer IV had to be used.Previous efforts to mount bigger guns on smaller chassis resulted in the Marder series as well as StuG IIIs. The Marder series were tall and had open crew compartments. The new design had a low silhouette and completely enclosed fighting compartment.

The Jagdpanzer IV used Panzer IV chassis 7 (known as BW7), but the almost-vertical front hull plate was replaced by sloped armor plates. Internally, the layout was changed to accommodate the new superstructure, moving the fuel tanks and ammunition racks[clarification needed]. Since the Jagdpanzer lacked a turret, the engine which originally powered the Panzer IV's turret could be eliminated.

The new superstructure had 80 mm thick sloped armour, which gives a much greater armor protection than a vertical armor of 100 mm. To make the manufacturing process as simple as possible, the superstructure was made out of large, interlocking plates which were welded together.

Armament consisted of a 7.5 cm main gun, originally intended to be the Pak 42 L/70, but due to shortages older guns were initially used, the 7.5 cm Pak 39 L/43 for preproduction, and the 7.5 cm Pak 39 L/48 for initial production variant. These were shorter and less powerful than the Pak 42.

Installing the much heavier Pak 42 meant that the Jagdpanzer IV was nose heavy, especially with the heavy frontal armor. This made them less mobile and more difficult to operate in rough terrain, leading their crews to nickname them Guderian-Ente ("Guderian's duck"). To prevent the rubber rims of the roadwheels being dislocated by the weight of the vehicle, some later versions had steel roadwheels installed on the front.

The final prototype of the Jagdpanzer IV was presented in December 1943 and production started in January 1944, with the Pak 39 L/48 armed variant staying in production until November. Production of the Pak 42 L/70 armed variants started in August and continued until March/April 1945.

On August 19–22, 1943, after the Battle of Kursk, Hitler received reports that StuG IIIs performed better than Panzer IV within certain restraints of how they were deployed. It was thus intended to stop production of the Panzer IV itself at the end of 1944 to concentrate solely on production of the Jagdpanzer IV, but the Panzer IV was in production all the way until the end of the conflict along with Jagdpanzer IV.

Variants

- Jagdpanzer IV 0-Serie

- with 7.5 cm Pak 39 L/43: a small number of these were built as the preproduction (0-Serie) probably in December 1943.[1]

- Jagdpanzer IV (Sd.Kfz.162[1])

- with 7.5 cm Pak 39 L/48, official name Sturmgeschütz neuer Art mit 7.5 cm Pak L/48 auf Fahrgestell PzKpfw IV, with 769–784 produced in January 1944 - November 1944.[1]

- Panzer IV/70 (V) (Sd.Kfz.162/1[1])

- was one of two variants armed with the same Pak 42 L/70 gun. The (V) stands for the designer, Vomag. The most produced version, with 930–940 built in August 1944 - April 1945.[1]

- Panzer IV/70 (A) (Sd.Kfz.162/1[1])

- the other Pak 42 L/70 armed Jagdpanzer IV. In order to send Pak 42 L/70 armed vehicles to the front as soon as possible, in July 1944 Hitler ordered an interim solution to speed up Nibelungenwerke's transition from Panzer IV production to Panzer IV/70 production. "A" stands for Alkett, a manufacturer of the StuG III, that was ordered to redesign the Jagdpanzer IV superstructure to be mounted onto a standard Panzer IV chassis. The Vomag design used a modified chassis permitting a very low silhouette, mounting the superstructure onto the original Panzer IV chassis required additional vertical steel plates mounted onto the chassis to counter height differences. The resulting vehicle was about 40 cm taller and lacked the sharp edged nose of the Vomag variant. Only 278 were built by Nibelungenwerke from August 1944 to March 1945.

Originally the Jagdpanzer IV's gun had a muzzle brake installed, but because the gun was so close to the ground, each time it was fired, huge dust clouds would rise up and betray the vehicle's position, leading many crews to remove the muzzle brake in the field. Later variants dispensed with the muzzle brake.

Early vehicles had zimmerit applied to the hull to protect against magnetic mines, but this was discontinued after about September 1944. Later vehicles had three return rollers rather than the original four, and adopted the twin vertical exhausts typical of the late Panzer IV series. Some late vehicles also had all-steel road wheels on the first couple of bogies on each side.

Combat history

The Jagdpanzer IV served in the anti-tank sections of Panzer and SS Panzer divisions. They fought in Normandy, the Battle of the Bulge and on the Eastern Front. They were very successful tank destroyers but performed badly when used out of role as substitutes for tanks or assault guns, as most tank destroyers were.In the later stages of the war however, they were increasingly used as tank substitutes, because there was often nothing else available.

Romania received several Jagdpanzer IV tank destroyers from the Red Army after the war ended. They were officially known as TAs T4 in the army inventory and were used until 1950. All German armour was scrapped in 1954.

One of the more notable Jagdpanzer IV aces was SS-Oberscharführer Rudolf Roy from the 12th SS Panzerjäger Battalion of 12th SS Panzer Division. He was killed by an American sniper while looking out of the hatch of his Jagdpanzer IV, on December 17, 1944 during the Ardennes Offensive in Belgium.

After the war, West Germany continued the Jagdpanzer concept with the Kanonenjagdpanzer, but few other fixed-casemate self-propelled guns were built postwar. An innovative exception was the Swedish Stridsvagn 103, or "S-Tank".

Survivors

- Jagdpanzer IV 0-Serie

- Deutsches Panzermuseum in Munster, Germany. The vehicle is a preproduction model with rounded front plates. It was previously part of the Musée des Blindés in Saumur, France

- Jagdpanzer IV L/48

- Deutsches Panzermuseum in Munster, Germany. It is an early version with 60 mm armor. This vehicle is on loan from the WTS in Koblenz, Germany, and previously belonged to the United States Army Ordnance Museum in Aberdeen, Maryland. It was returned to Germany in the 1960s.

- Musée des Blindés in Saumur, France. It is an early model with 60 mm armor.

- Thun Tank Museum in Switzerland. It is a late model with 80 mm front armor.

- In storage in a military area in Bulgaria. This is a very early L/48 model, and the only surviving example with the driver's machine gun slot welded over. It was previously part of a defensive line on the Bulgarian border. In February 2008 it was ordered recovered by the Bulgarian Defense Minister to be either preserved in a museum in Bulgaria, or sold to a private collector.

- Panzer IV L/70 (V)

- National Museum of Military History in Sofia, Bulgaria.

- Kubinka Tank Museum in Russia.

- United States Army Ordnance Museum located in Aberdeen, Maryland.

- Patton Museum located at Fort Knox, Kentucky. This vehicle was previously part of the Shrivenham Study Collection in the UK.

- Canadian War Museum located in Ottawa, Canada. This vehicle was previously at the Canadian Forces Base/Area Support Unit Shilo in Canada.

- Panzer IV L/70 late (A)

- Musée des Blindés in Saumur, France. The vehicle was used in 1944-45 by Free French forces. The vehicle is displayed with damage resulting from a direct hit by an armor-piercing shell.

- Wrecks

SU-85

From Wikipedia, the free encyclopedia

| SU-85 | |

|---|---|

SU-85 tank destroyer in Polish Army Museum.

|

|

| Type | Tank destroyer |

| Place of origin | |

| Service history | |

| In service | 1943 - 1950s (USSR) |

| Production history | |

| Designer | Lew S. Trojanow |

| Designed | 1943 |

| Produced | mid-1943 - late 1944 |

| Number built | 2,050 |

| Variants | See Variants section |

| Specifications | |

| Weight | 29.6 tonnes (65,256 lbs) |

| Length | 8.15 m (26 ft 9 in) overall 6.10 m (20 ft) hull only |

| Width | 3 m (9 ft 10 in) |

| Height | 2.45 m (8 ft) |

| Crew | 4 (commander, driver, gunner, loader) |

| Armor | 45 mm(1.77 in) |

Main

armament |

85 mm (3.34 in) D-5T gun |

Secondary

armament |

none |

| Engine | V-2 12-cylinder diesel 500 PS ( 493 hp, 368 kW) |

| Power/weight | 16,89 PS/tonne (12.43 kW/tonne) |

| Suspension | Christie |

| Ground clearance | 400 mm (16 in) |

| Fuel capacity | 540 l 810 l - 900 l (with additional fuel tanks) |

Operational

range |

400 km (248 mi) (road) |

| Speed | 55 km/h (34 mph) (road) |

|

||

Contents

Development history

Early in World War II, Soviet tanks such as the T-34 and KV-1 had adequate firepower to defeat any of the German tanks then available. By the fall of 1942, Soviet forces began to encounter the new German Tiger tank, with armor too thick to be penetrated by the 76.2 mm guns used in the T-34 and KV tanks at a safe range.[1] The Soviet command also had reports of the Panther tank, a new, heavily armoured German tank then under development. Although the Panther was not seen in combat until July 1943, the new generation of German vehicles meant the Red Army would need a new, more powerful main gun for their armoured formations.In May 1943, work was begun on a new anti-tank gun. Military planners directed the design bureaus of both Gen. Vasiliy Grabin and Gen. Fyodor Petrov to modify the 85mm anti-aircraft gun for use as an anti-tank weapon. Petrov's bureau developed the D-5 85mm gun. Though much too large for the T-34 or KV-1 turret, it was thought the gun could be mounted upon the chassis of the SU-122 self-propelled gun to give the weapon mobility. The version of this gun intended to be mounted upon the SU-85 was called the D-5S, with the "S" standing for self-propelled. Initially the production factory at Uralmash rejected the proposed design. Nevertheless, the administrators at Uralmash were persuaded to proceed, and the new design was put into production. The weapon was later modified to include a telescopic sight and a new ball gun mantlet. This vehicle was retitled the SU-85-II.[1]

Description

The SU-85 was a modification of the earlier SU-122 self-propelled howitzer, essentially replacing the 122 mm M-30S howitzer of the SU-122 with a D-5T high-velocity 85 mm antitank gun. The vehicle had a low profile and excellent mobility. The limited traverse of the main armament meant that the gun had to be aimed by changing the position of the tank, limiting its effectiveness in offensive operations.Production history

SU-85 production started in mid-1943, with the first vehicles reaching their units by August. When the up-gunned T-34-85 medium tank entered mass production in the spring of 1944, there was no point in continuing production of a tank destroyer without superior firepower,[2] so SU-85 production was stopped in late 1944 after 2,050 vehicles had been produced. It was replaced on the production lines by the SU-100 tank destroyer, armed with the more powerful 100 mm D-10S gun.There were two versions: the basic SU-85 had a fixed commander's cupola with a rotating periscope and three vision blocks; the improved SU-85M had the same casemate as the later SU-100, with a commander's cupola as used on the T-34-85.

Service history

The SU-85 was withdrawn from Soviet service soon after the war, and was exported to many Soviet client states in Europe and elsewhere. Some SU-85s were converted to use as command and recovery vehicles.[3] In places such as North Korea and Vietnam it remained in service for many years.[4]

Variants

Former Soviet Union

- SU-85 Basic version with four periscopes and no commander's cupola.

- SU-85M Improved version with SU-100 style cupola.

Poland

- WPT-34 (1960s) - Polish repair and maintenance vehicle with a superstructure replacing the casemate, a crane, a large-diameter telescoping snorkel for deep fording operations as well as a large-spade type earth anchor in the rear. It was converted from SU-85 tank destroyers as well as T-34 medium tanks and SU-100 tank destroyers.

See also

- List of Soviet tanks - covers all periods

SU-100

From Wikipedia, the free encyclopedia

|

|||||||||||||||||||||||||||||||||||||||||||||

For the airplane, see Sukhoi Superjet 100.

The SU-100 was a Soviet casemate-style tank destroyer armed with a powerful 100 mm anti-tank gun. It was used extensively during the last year of World War II and saw service for many years afterwards with the armies of Soviet allies around the world.Development

The SU-85 was developed from the same chassis as the T-34 tank, but replaced its turret with a casement installation allowing larger guns to be fitted. This was used with the 85 mm D-5 gun, providing dramatically upgraded firepower compared to the T-34's 76.2 mm models. Introduced to service in 1943, the SU-85 was quickly rendered obsolete when designers managed to mount the same gun on the T-34-85.This led to efforts to up-gun the SU-85 as quickly as possible. Development was conducted under supervision of L. I. Gorlitskiy, chief designer of all medium Soviet self-propelled guns. The work started in February 1944 and first prototype of SU-100, called "Object 138", was built in March. After intensive testing with different models of 100 mm gun Soviet engineers approved the D-10S gun for mass production. This gun was developed in Constructors Bureau of Artillery Factory No. 9 under guidance of F. F. Petrov. After the Second World War this gun was installed on T-54 and T-55 tanks and its derivatives were in service forty years after initial development.

It was built at the UZTM (Russian abbreviature УЗТМ for Уральский Завод Тяжелого Машиностроения – Ural Heavy Machinery Factory, also called Uralmash) in Yekaterinburg. The SU-100 quickly proved itself to be among the best self-propelled anti-tank guns of World War II, able to penetrate 125 mm (4.9 in) of vertical armor from a range of 2,000 m (1.2 mi) and the sloped 85 mm (3.3 in) front armor of the German Panther from 1,500 m (0.93 mi).[citation needed]

The hull of SU-100 had major improvements over the SU-85; the thickness of the front armour was increased from 45 to 75 mm (1.8 to 3.0 in), and the commander's workplace was made in a small sponson on the right side of the hull; combined with the commander's cupola this greatly improved the commander's effectiveness. For better ventilation two ventilator units were installed, instead of only one as in the SU-85. Mass production began in September 1944.

In service

The vehicle remained in service with the Red Army well after the war; production continued in the Soviet Union until 1947 and into the 1950s in Czechoslovakia. It was withdrawn from Soviet service in 1957 but many vehicles were transferred to reserve stocks. Some exist to this day in the Russian Army holding facilities.

Many Warsaw Pact countries also used the SU-100, as did Soviet allies such as Egypt, Angola and Cuba. A few SU-100 were delivered to Yugoslavia after the war, under the designation M-44.[1] The SU-100 saw service in the fighting that accompanied the 1956 Suez Crisis, in which the Egyptians used SU-100s against Israel's M4 Sherman tanks. The vehicle was also utilized in the 1967 Six-Day War and the 1973 Yom Kippur War. It was modified slightly to adapt it to the sandy conditions of the Middle East, thus creating the SU-100M variant. Exported SU-100s continued in service until the 1970s, and in some countries, even later. Yugoslavs used them during the civil war however due to lack of spare parts they were quickly retired, but performed satisfactorily. The SU-100 remains in use by the Vietnam People's Army and the Korean People's Army Ground Force despite the age of the design.

SU-100s entered service with the People's Liberation Army (PLA) of China after 1 December 1950 when Soviet forces left Dalian. The armaments in Dalian were sold to China, including 99 SU-100s, 18 IS-2 heavy tanks, 16 T-54s and 224 T-34s, with which PLA formed its 1st Mechanised Division.

In popular culture

The crew of a World War II SU-100 and their vehicle are the heroes of the old Soviet film «На войне как на войне» Na vojne kak na vojne ("All's fair in love and war", literally: "In wartime it's like wartime"), one of several Soviet films made about self-propelled artillery men. Veterans of the German-Soviet War found this picture quite realistic. The movie includes a Soviet tankmen song, which is popular with both Russian armoured soldiers and civilians.A SU-100 is used by the protagonists in the movie The Misfit Brigade, where it is portrayed as a German tank, because it was readily available in Yugoslavia (where the movie was shot) and for its passable resemblance to German turretless Assault Guns and Tank Destroyers. Ironically, the film has a scene where the Germans spot one, supposedly captured by the Russians, and proclaim: "That's one of ours! It sure is, and it's a terrible paint job. You can still see the cross! ... Ivan's pinched my tank!" The film is also known as Wheels of Terror, based on the book by Sven Hassel.

Jagdpanther

From Wikipedia, the free encyclopedia

| Jagdpanther | |

|---|---|

Jagdpanzer V Jagdpanther

|

|

| Type | Tank destroyer |

| Place of origin | Nazi Germany |

| Production history | |

| Produced | 1944–1945 |

| Number built | 415 |

| Variants | G1, G2 |

| Specifications | |

| Weight | 45.5 tonnes (100,300 lb) |

| Length | 9.87 m (32 ft 5 in) |

| Width | 3.42 m (11 ft 3 in) |

| Height | 2.71 m (8 ft 11 in) |

| Crew | 5 |

| Armor | 80 mm (3.14 in) frontal 100 mm (3.93 in) mantlet 45mm side 40mm rear |

Main

armament |

1 × 8.8 cm Pak 43/3 or 43/4 L/71 57 rounds |

Secondary

armament |

1 × 7.92 mm Maschinengewehr 34 600 rounds |

| Engine | Maybach HL230 P30 (V-12 petrol) 700 PS (690 hp, 515 kW) |

| Power/weight | 15.4 PS/tonne |

| Suspension | dual torsion bar |

Operational

range |

160 km (99 miles) |

| Speed | 46 km/h (28.6 mph) |

Contents

Development

The Jagdpanther had been preceded by two attempts at mounting an 8.8 cm gun as a self-propelled anti-tank weapon; Ferdinand using the ninety-one leftover Porsche-built VK4501(P) chassis from the Tiger tank competition it had lost to Henschel in 1942, and the Nashorn using a Panzer III/IV chassis. Ferdinand proved to be too heavy and Nashorn small and underpowered.[1]A heavy tank destroyer design based on the 8.8 cm Pak 43 gun and the Panther tank chassis was ordered in late 1942 as design SdKfz 173. The prototype by MIAG was demonstrated in October 1943 before Hitler.

Production started in January 1944; in February Hitler specified the simpler Jagdpanther name instead of its original "8.8 cm Pak 43/3 auf Panzerjäger Panther".

It was armed with the same long-barreled 8.8 cm gun as the Tiger II "King Tiger". The gun was mounted in a central mantlet which gave it a limited traverse of 11 degrees to each side. A single 7.92 mm MG-34 machine gun for local defence was in a ball mount right hand side of the front glacis plate. The machine gunner was also the wireless operator. The driver sat on the left. The gunner had a rangefinder and a periscope telescopic sight. The periscope - linked to the gun mount - was under an armoured housing on the roof.

The Jagdpanther had a good power-to-weight ratio and a powerful main gun, which enabled it to destroy any type of Allied tank. Based on the existing Panther Ausf G chassis, the vehicle did not suffer too many mechanical problems. It had an upgraded transmission (the ZF AK 7-400 heavy duty) - which had been planned for the Panther II - and final drive to counter the Panther's main weakness. It was manned by a crew of five: a driver, radio-operator, commander, gunner and a loader.[2]

Two main variants can be distinguished, the earlier (1944 model) G1 with a small internally bolted main gun mantlet and a modified Panther A engine deck, and the later (1945 model) G2 with a larger simplified, outside-bolted mantlet and a modified Panther G engine deck, though late G1s also had the larger mantlet. Early Jagdpanthers had two vision openings for the driver, whereas late versions had only one. The main gun originally had a monobloc gun barrel but later versions were equipped with the Pak 43/4 gun with a two-part barrel. The two part barrel was more economical as barrel wear was not even.[2]

Early G1s (to September 1944) were given Zimmerit anti-magnetic mine coating in a distinctive "small-squared" pattern.

Production and service

Jadgpanthers equipped heavy antitank battalions (schwere Panzerjäger-Abteilung) and served mainly on the Eastern Front.[citation needed] In the West, they were first encountered in very small numbers late in the Battle of Normandy, where the German 654 schwere Panzerjäger-Abteilung ("654th Heavy Antitank Battalion") deployed about 12 Jagdpanthers against British units. Later, significant numbers were concentrated in the West for the Ardennes Offensive.

Survivors

Three surviving Jagdpanthers have been restored to running condition. Two German museums, the Deutsches Panzermuseum at Munster and the Wehrtechnische Studiensammlung (WTS) at Koblenz, have one running Jagdpanther each. The SDKFZ Foundation in the UK has restored one Jagdpanther to running condition, using two wrecked Jagdpanthers to complete one. The other wreck will also be restored.[citation needed]There are at present seven other known surviving Jagdpanthers, which are on display at:

- Bovington Tank Museum, Dorset, UK—one of a number assembled by British Army Royal Electrical and Mechanical Engineers for trials, late production model.[4]

- Imperial War Museum, London, UK. Early production variant. This has three shot penetrations on the right side of the engine compartment while the left side has been sectioned and opened to public view.[5]

- Kubinka Tank Museum, Moscow, Russia

- Musée des Blindés in Saumur, France

- Sinsheim Auto & Technik Museum, Sinsheim, Germany

- Panzermuseum Thun, Thun, Switzerland

- United States Army Ordnance Museum, Aberdeen, USA

- The Wheatcroft Collection in the UK owns a small collection of parts of Jagdpanthers and hopes to restore one.[6]

Media appearances

- The 1950 film They Were Not Divided (1950) features a Jagdpanther.

- One can be seen in It Happened Here (1965)

- The HBO miniseries Band of Brothers, episodes "Carentan" and "Replacements" feature a replica Jagdpanther which had been built on a Soviet T-55 tank chassis.

See also

B1 Centauro

From Wikipedia, the free encyclopedia

For the armoured division see 131 Armoured Division Centauro.

| Centauro | |

|---|---|

B1 Centauro with IFOR Markings.

|

|

| Type | Wheeled Tank Destroyer |

| Place of origin | |

| Specifications | |

| Weight | 24,000 kg |

| Length | 7.85 m (25 ft 9 in) |

| Width | 2.94 m (9 ft 8 in) |

| Height | 2.73 m (8 ft 11 in) |

| Crew | 4 (commander, gunner, loader and driver) |

| Armor | Welded steel armoured hull |

Main

armament |

105 mm gun |

Secondary

armament |

2x7.62 mm MGs |

| Engine | IVECO Diesel 520 hp |

| Power/weight | 19.35 hp/tonne |

| Suspension | Wheel 8 x 8 |

Operational

range |

800 km (500 mi) |

| Speed | 108 km/h (67 mph) |

Contents

Description

The vehicle was developed in response to an Italian Army requirement for a tank destroyer with the firepower of the old Leopard 1 main battle tank then in service with the Italian Army but with greater strategic mobility. The main mission of the Centauro is to protect other lighter elements of the cavalry, using its good power-to-weight ratio, excellent range and cross country ability (despite the wheeled design) and computerized fire control system to accomplish this mission. Centauro entered production in 1991 and deliveries were complete by 2006.Armament

The main armament consists of the Oto Melara 105 mm / 52 caliber gyro-stabilized high-pressure, low-recoil gun equipped with a thermal sleeve and an integrated fume extractor, with 14 ready rounds in the turret and another 26 rounds in the hull. The gun can fire standard NATO ammunition, including APFSDS (Armour Piercing Fin-Stabilized Discarding Sabot) rounds.Secondary weapons are a 7.62 mm coaxial machine gun, and another 7.62 mm anti-aircraft machine gun with 4,000 rounds of ammunition.

Aiming is provided by Galileo Avionica TURMS fire control system (the same fitted to the Italian Ariete tank) and is equipped with a muzzle referencing system and a fully digital ballistic computer. The gunner sight is fully stabilized and comes equipped with a thermal imager and laser rangefinder. The commander's station is equipped with a panoramic stabilized sight, an image intensifying night sight and a monitor displaying the image from the gunner's thermal sight. This allows Centauro to engage stationary or moving targets while stationary or on the move, in day or night.

Armour

The Centauro hull is an all-welded steel armoured hull which is designed to withstand in the baseline configuration 14.5 mm bullets and shell fragments with protection against 25 mm munition on the frontal section. Protection can be increased by the addition of bolt on appliqué armour which increases protection against 30 mm rounds.The Centauro is also equipped with an NBC (Nuclear, Chemical and Biological) warfare protection system which is integrated with the vehicle's air conditioning system. The vehicle is also equipped with a four-barreled smoke grenade launcher mounted on each side of the turret and a laser warning receiver.

Propulsion

Centauro is powered by an Iveco V6 turbo-charged after-cooled diesel engine delivering 520 hp (382.4 kW). This drives a ZF-designed automatic transmission which is manufactured under license by Iveco Fiat. The transmission system has five forward and two reverse gears. This drives 8 wheels which are each equipped with an independent suspension system and is furthermore equipped with run-flat inserts and a Central Tyre Inflation System (CTIS). Braking is provided by 8 disc brakes. Steering is provided on the first and second axles and at slow speed with also the fourth axle. Together, this allows Centauro to achieve road speeds in excess of 100 km/h, negotiate gradients up to 60%, ford water up to a depth of 1.5m without preparation, and have a turning radius of 9m.Combat history

Centauro was deployed in the former Yugoslavia and Somalia, where the design proved successful. Centauro was usually employed to escort motor convoys, for wide area control and for road patrols. Centauros were also deployed during operation Antica Babilonia, the Italian involvement in the Iraq War. During this operation, a Centauro troop took part in the battle for the bridges of Nassiriya, destroying a building where snipers were hiding.[1] It is currently deployed as part of UNIFIL forces in Lebanon.Variants

- Centauro Reconnaissance Anti-Tank Variant:

- The baseline variant.

- Centauro 120 mm

- A Centauro with a low recoil 120/45 cannon, in newly designed turret and with new composite armour that can resist up to 40mm APFSDS rounds on the front.

- Freccia a wheeled infantry fighting vehicle

An early prototype, armed with a 155x39 gun, was seen at the national Italian holiday of 2 June (2011).

A known AAA and c-ram prototype version, called "Draco", is armed with a 76 mm automatic cannon, and with Strales directional ammunition system.

A 125 mm gun-armed version is being tested by the Russian army, alongside the standard 105 mm-armed version.[2]

Operators

Italian Army

Italian Army- 400 Centauro Reconnaissance Anti-Tank Variant (around 100 vehicles from the first batches retired)

- 249 VBM Freccia (172 standard, 36 combat anti-tank, 20 command center and 21 mortar carrier on order)

- 4 VBM Freccia Ambulance Variant

Spanish Army

Spanish Army- 84 Centauro Reconnaissance Anti-Tank Variant

- 4 VBM Freccia Recovery Variant

Royal Army of Oman

Royal Army of Oman- 6+3 Centauro 120 mm Variant (option for further 24)

US Army

US Army- Leased 16 Centauro between 2000 and 2002 for evaluation, and to gain experience for the introduction of the Stryker Mobile Gun System.[3]

M40 recoilless rifle

From Wikipedia, the free encyclopedia

| M40 Recoilless Rifle | |

|---|---|

Greek infantry with an M40

|

|

| Type | Recoilless rifle |

| Place of origin | United States |

| Service history | |

| In service | Mid 1950s–present |

| Used by | See Users |

| Wars | Vietnam War Cambodian Civil War Portuguese Colonial War Indo-Pakistani War of 1971 Rhodesian Bush War Falklands War[citation needed] Iran–Iraq war Libyan Civil War Syrian Civil War |

| Production history | |

| Manufacturer | Watervliet Arsenal |

| Specifications | |

| Weight | 209.5 kg (462 lb) |

| Length | 3.404 m (11 ft 2 in) |

| Height | 1.12 m (3 ft 8 in) |

| Shell | 106×607mmR (HEAT, HEP, HEAP, Canister) |

| Caliber | 105 mm (4.1 in) |

| Recoil | Recoilless |

| Carriage | Tripod |

| Elevation | -17° to +65° (between mount legs) -17° to +27° (over mount leg)[1] |

| Traverse | 360° |

| Muzzle velocity | 503 m/s (1,650 ft/s)[1] (M344 HEAT) |

| Effective firing range | 1,350 m (1,480 yd) |

| Maximum firing range | 6,870 m (M346A1 HEP-T)[2] |

The M27 recoilless rifle was a 105-mm weapon developed in the early 1950s and fielded in the Korean War. Although a recoilless rifle of this caliber had been a concept since the Second World War, the weapon was hurriedly produced with the onset of the Korean War. The speed with which it was developed and fielded resulted in problems with reliability caused by trunnions that were mounted too far to the rear. The M27 was also considered too heavy by the U.S. Army and had a disappointing effective range due to the lack of a spotting rifle. Taking the M27 as a the basis for a new design, the Army developed an improved version of the M27 that was in 1955 type-designated the M40 106-mm recoilless rifle.[5] Originally along with its type-designation it was also given the official name BAT for Battalion Anti-Tank gun, but that was soon dropped.[6] Although unsuitable for military purposes, M27 recoilless rifles were used to trigger controlled avalanches at ski resorts and mountain passes in the United States.[7]

The M40 primarily saw action during the Vietnam War and was later replaced by the BGM-71 TOW anti-tank missile system. The weapon was also used by anti-communist forces in Angola mounted on Land Rovers.

Contents

Description

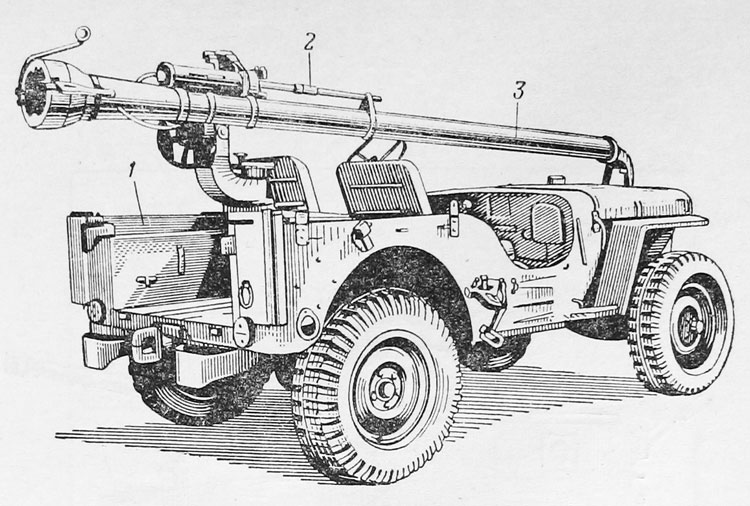

The M40 is shaped like a long tube with an M8 0.50 cal spotting rifle above. The spotting rifle fires a round whose trajectory closely matches that of the 106 mm round and gives off a puff of smoke on impact with the target. On the left hand side, there is an elevating wheel, in the centre of which is the trigger wheel used to fine adjust the elevation and at the same time firing the spotting rifle when pulled, and the gun when pushed. The mounting is a tripod, but the front leg has a castoring wheel. On top of the mount is a traverse wheel. On the centre of the traverse wheel is a locking wheel, when the wheel is down, the rifle is locked in traverse, and can only be moved right and left with the traverse wheel. When the wheel is raised, the rifle can be traversed by hand. Austria produced a two-wheeled mount for the M40.The whole mounting can be placed on an M151 Jeep for mobile use. It has also been mounted on Willys Jeep M 38A1 Land Rover Defenders, M113s, Mercedes-Benz G-Wagen, HMMWVs, Toyota Land Cruisers, AIL Storms and M274 Mechanical Mules. They were also used on US Navy minesweepers (MSO) during Operation Market Time in Vietnam.

A special vehicle called Ontos carried six M40s. A version specific to the T195E5 mount, the M40A1C, was used. It was used only by the U.S. Marine Corps. Japan produced a self-propelled gun called the Type 60 which carried two side by side. Some Pakistani M113s have a dual mounting.

The M40 was a very successful export item and continues to be used by South Korea (ROK), Ecuador, Egypt, Estonia, Greece, Honduras, Iran, Israel, Lebanon, Malaysia, Mexico, Morocco, the Philippines, Taiwan (Republic of China Marine Corps), Turkey, Colombia, Cambodia, Vietnam, Venezuela and many others, as well as anti-government forces in the Libyan Civil War and Syrian civil war.[8]

In the period 1958 - 1990 the antitank companies of the Swiss Army Infantry Regiments were equipped with 12 M40 guns.

It is manufactured in Iran by Defense Industries Organization as the ANTI-TANK GUN 106.[9]

Ammunition

Ammunition for the 105 mm rifle was issued as one-piece fixed cartridges. The term "fixed" means that the projectile and the cartridge case are crimped together. This ensures correct alignment of the projectile and the cartridge case. It also permits faster loading because the projectile and the cartridge case are loaded as one unit. The rear end of the cartridge case is perforated, to allow the propellant gas to escape through the vented breech, thus neutralizing recoil. Most projectiles (except HEAT) used are pre-engraved, that is, the rotating bands are cut to engage the rifled bore.[10] If the round was not rotated slightly when loading the M40 it could result in jamming in the breach.Types of ammunition included HEAT, High Explosive Plastic-Tracer (HEP-T), canister, High Explosive Anti Personnel, and the M368 dummy round which could not be fired and was used for crew drill. The original U.S. HEAT round penetrated more than 400 mm of armor. Near the end of the M40's service life, both Austria and Sweden produced HEAT rounds for the weapon capable of penetrating more than 700 mm of armor.[11]

Gallery

-

U.S. Marines manning an M40 during the Battle of Huế in the Vietnam War.

Recoilless rifle

From Wikipedia, the free encyclopedia

A recoilless rifle (RCLR) or recoilless gun is a type of lightweight tube artillery that is designed to allow some of the propellant gases to escape out the rear of the weapon at the moment of ignition, creating forward thrust that counteracts some of the weapon's recoil. This allows for the elimination of much of the heavy and bulky recoiling mechanisms of a conventional cannon while still enabling the unit to fire a powerful projectile. Besides this, the lower pressures involved allow thinner walled and lighter tubes, lowering further the weight of the cannon. Technically, only devices that use a rifled barrel are recoilless rifles. Smoothbore variants are recoilless guns. This distinction is often lost, and both are often called recoilless rifles.[1]

Though it is similar in form and appearance to a rocket launcher, it fires modified artillery shells, not rockets. The key difference from rocket launchers (whether man-portable or not) is that the projectile of the recoilless rifle has no propulsion of its own—once out of the rifle, it behaves as a normal artillery shell and does not accelerate further, as a missile or rocket would. Nevertheless there are also boost-after-launch rocket-propelled projectiles available for modern recoilless rifles.

Normally used for anti-tank roles, the first effective system of this kind was developed during World War II by William Kroeger and Clarence Musser.[2]

Since some projectile velocity is inevitably lost to the recoil compensation backblast, recoilless rifles tend to fire a fairly heavy explosive shell with less range than traditional cannon, although with a far greater ease of transport, making them popular with paratroop, mountain warfare and special forces units where portability is of particular concern, as well as with some light infantry and infantry fire support units. Although the greatly diminished recoil allows many smaller and newer versions to be shoulder-fired by individual infantrymen, the majority of recoilless rifles in service are mounted on light tripods and intended to be carried by a small 2- or 3-man crew. The largest versions, such as the British 120 mm L4 MoBAT and L6 Wombat, retain enough bulk and recoil to be restricted to a firm vehicular mount, such as on a jeep, truck or armored personnel carrier.

The typical recoilless gun functions very much like a conventional gun. The projectile and propellant are supplied as a single round and loaded into the breech. When fired, however, instead of all the propellant blast following the projectile out the barrel, a large portion is allowed to escape to the rear, gaining a rearward directed momentum which is nearly equal to the forward momentum of the projectile. This balance of momenta ensure that the momentum of the rifle/projectile/exhaust gas system is conserved without imparting much momentum (recoil) to the rifle itself. Since recoil has been mostly removed, the heavy and complex gun carriage and recoil damping mechanism can be dispensed with. Despite the name, it is rare for the forces to completely balance, and real-world recoilless rifles do recoil noticeably (with varying degrees of severity). Recoilless rifles are maintenance-intensive weapons,[citation needed] and if the breech and gas ports are old, damaged, plugged or poorly maintained, the recoil-damping effect can be reduced or lost altogether, leading to dangerously powerful recoil. Conversely, if a projectile becomes lodged in the barrel for any reason, the entire weapon will recoil forward, in the manner of a rocket.

Unlike a rocket launcher, which fires fin-stabilized rockets from a smooth bore, recoilless rifle rounds resemble conventional artillery shells. They generally have a pre-engraved rifling band to engage the rifled launch tube, spin-stabilizing the projectile, hence the term "rifle". The "case" area of the shell can be perforated to vent the propellant gases which are then directed to the rear, as the base of the shell disintegrates.

Since venting hot gases to the rear can be dangerous in confined spaces, some recoilless guns such as the Armbrust and MATADOR use a combination of a countershot, smoothbore barrel and pistons to avoid both recoil and back blast. The fin stabilized Armbrust "cartridge" contains the propellant charge between two pistons with the warhead in front of one, facing forward, and an equal countermass of shredded plastic in front of the other piston. Upon firing, the propellant expands rapidly pushing the pistons outward. This pushes the projectile forwards towards the target and the countermass backwards providing the recoilless effect. The shredded plastic countermass is quickly slowed by air resistance and is harmless at a distance more than a few feet from the breech. The pistons jam at the ends of the barrel trapping the hot propellant gases inside. All this allows safe firing in enclosed spaces.

In the Soviet Union, development of recoilless weapons ("Dinamo-Reaktivnaya Pushka" (DRP), roughly "dynamic reaction cannon") began in 1923. In the 1930s many different types of weapons were built and tested with configurations ranging from 37 mm to 305 mm. Some of the smaller examples were tested in aircraft (Grigorovich I-Z and Tupolev I-12) and saw some limited production and service, but development was abandoned around 1938. The best-known of these early recoilless rifles was the Model 1935 76 mm DRP designed by Leonid Kurchevsky. A small number of these mounted on trucks saw combat in the Winter War. Two were captured by the Finns and tested; one example was given to the Germans in 1940.

The first recoilless rifle to enter service in Germany was the 7.5 cm Leichtgeschütz 40 ("light gun" '40), a simple 75 mm smoothbore recoilless gun developed to give German airborne troops artillery and anti-tank support that could be parachuted into battle. The 75 was found to be so useful during the invasion of Crete that a larger 105 mm version was developed on the same basic pattern. Interestingly both of these weapons were loosely copied by the US Army, reversing the flow of technology that had occurred when the Germans copied the Bazooka, as their own 88 mm calibre Panzerschreck infantry anti-tank rocket system. The US did have a development program and it is not clear to what extent the design was copied, as there were in fact differences. The Japanese had also developed a portable recoilless anti-tank rifle which they had reserved for the defense of the anticipated invasion of the mainland. As it was, however, these weapons remained fairly rare during the war although the US versions of the 75 started becoming increasingly common in 1945.

During the Second World War the Swedish company Bofors Carl Gustaf developed a small 20 mm device, the 20 mm m/42; the British expressed their interest in it, but by that point anti-tank rifles were already out of date.

In 1947, the US 75 mm was acquired as war surplus by the French military and mounted on a Vespa scooter. It was used by French paratroops as a mobile anti-tank and anti-fortification platform and saw service in Algeria and Indochina.

By the time of the Korean War, recoilless rifles were found throughout the US forces. The "original" US recoilless rifles were the 57mm and 75mm, followed by a 105 mm (the unsuccessful M27). Newer models replacing these were the 90 mm M67 and 106 mm M40 (which was actually 105 mm caliber but designated otherwise to prevent confusion of ammunition with the earlier model). The Soviets likewise adopted recoilless technology in the 1950s, most commonly in calibers 73 mm, 82 mm, and 107 mm .

The British, whose efforts were led by Denis Burney, inventor of the Wallbuster HESH round, also developed recoilless designs. Burney demonstrated the technique with a recoilless 4-gauge shotgun. His "Burney Gun" was developed to fire the Wallbuster shell against the Atlantic Wall defences, but was not required in the D-Day landings of 1944. He went on to produce many designs including a man-portable 3.45" (88 mm) recoilless rifle, the Ordnance, RCL, 3.45 in, pushed into experimental service in late 1945.

Two Burney guns were designed primarily as anti-tank weapons. One was 3.45 inches in calibre and could be fired off a man's shoulder or from a light tripod. The other was 3.7 inches in calibre, and was carried on a light two-wheeled mounting. The "Ordnance RCL. 3.45in MK 1" weighed 75 lb (34 kg), was 68.5in (1.74m) long, and fired an 11 lb (5 kg) wallbuster shell to 1,000 yards. No penetration figures were ever made public. but it is fairly certain that it could knock a 10 lb slab off the back of 6 in (150 mm ) of armour plate at any range it could hit. The 3.7 was a larger weapon weighing 222 lb (100 kg); it was 112 in (2.84 m) long and fired a 22.2 lb (10 kg) wallbuster to 2,000 yards; it is estimated that this could have dealt successfully with armour up to 10 in (254 mm) thick. Post-war work developed and deployed the BAT series of recoilless rifles, culminating in the 120 mm L6 Wombat ("Weapon of Magnesium, Battalion Anti-tank"). This was too large to be transported by infantry, and was usually towed by jeep. The weapon was aimed via a spotting rifle, which fired .50 BMG rounds whose trajectory matched that of the main weapon. Tracer rounds were fired first until hits were observed before firing off the main gun.

Lightweight SPG-9 73 mm and B10 82 mm heavy recoilless rifles are still in service in the Russian army in airborne units, and are found quite commonly around the world in the inventories of former Soviet client states, where they are usually used as antitank guns.

During the 1960s and 1970s, wire-guided missiles began to supplant recoilless rifles in the anti-tank role. The recoilless rifle started to disappear from the military except in areas such as the Arctic where battery-powered Dragons and wire-guided TOWs would fail due to extreme low temperatures. The former 6th Light Infantry Division in Alaska used the M67 in its special weapons platoons, as did the Ranger Battalions and the US Army's Berlin Brigade. The last major use was the M50 Ontos, which mounted six of the US 106 mm on a light (9 ton) tracked chassis first developed for use by the US Army airborne troops in 1950. However the Army considered them useless, and the Marines adopted the vehicle in a limited role. They used them to great effect as an anti-personnel fire support vehicle during the Vietnam War. The crews continued to report that the Ontos was a very effective fighting vehicle in this role, but the military brass continued to argue for heavier designs, and in 1970 the Ontos was removed from service and most were broken up. However the recoilless rifle found other roles, most notably in the India-Pakistan confrontation in Kashmir, where it was used against bunkers and as artillery in otherwise inhospitable terrain.

The Viet Minh also developed their own recoilless rifle under the direction of Tran Dai Nghia. The Vietnamese version was named SKZ or Sung khong giat (a Vietnamese translation of "recoilless rifle") and was used intensively in assaulting the French bunkers and fortified positions. The larger version of SKZ was DKZ or Phao khong giat ("recoilless artillery").

Today one of several remaining front-line recoilless rifles in the armies of industrialized nations is the famous Carl Gustav recoilless rifle, an 84 mm man-portable anti-tank weapon. First introduced in 1946, it is still in widespread use throughout the world today, and has even been re-introduced into the US Marine Corps as an anti-bunker weapon. The 84 mm (Carl Gustav recoilless rifle) can be used, along with 66 mm (AKA M72 LAW) and LAW 80 for mouse-holing whilst fighting in built-up areas (FIBUA). This is where impromptu "doors" are added to a building to gain entry, hopefully avoiding the prepared defences of the occupiers. Many nations also use a weapon related to the Carl Gustav, the one-shot AT-4 recoilless weapon.

Another recoilless rifle still in use is the Italian-made 80 mm Breda Folgore, which was introduced in 1986 and built up to 2001. It is available in a shoulder-launched and in a tripod-mounted version. The use of boost-after-launch rocked-propelled projectiles gives the weapon a long effective range, compared to similar weapons.

The US-made, M40 106 mm recoilless rifles, usually mounted on jeeps or similar small vehicles, are very common in the armies of many countries, where they serve in the role of tank destroyers.

Deployed by the United States in the 1960s, the Davy Crockett used a recoilless smooth bore gun to launch a tactical nuclear warhead.

Older recoilless rifles are still used by the U.S. National Park Service and the U.S. Forest Service as a system for avalanche control. The Washington State Department of Transportation uses a 105 mm recoilless rifle for avalanche control on Interstate 90.[3]

Though it is similar in form and appearance to a rocket launcher, it fires modified artillery shells, not rockets. The key difference from rocket launchers (whether man-portable or not) is that the projectile of the recoilless rifle has no propulsion of its own—once out of the rifle, it behaves as a normal artillery shell and does not accelerate further, as a missile or rocket would. Nevertheless there are also boost-after-launch rocket-propelled projectiles available for modern recoilless rifles.

Normally used for anti-tank roles, the first effective system of this kind was developed during World War II by William Kroeger and Clarence Musser.[2]

Since some projectile velocity is inevitably lost to the recoil compensation backblast, recoilless rifles tend to fire a fairly heavy explosive shell with less range than traditional cannon, although with a far greater ease of transport, making them popular with paratroop, mountain warfare and special forces units where portability is of particular concern, as well as with some light infantry and infantry fire support units. Although the greatly diminished recoil allows many smaller and newer versions to be shoulder-fired by individual infantrymen, the majority of recoilless rifles in service are mounted on light tripods and intended to be carried by a small 2- or 3-man crew. The largest versions, such as the British 120 mm L4 MoBAT and L6 Wombat, retain enough bulk and recoil to be restricted to a firm vehicular mount, such as on a jeep, truck or armored personnel carrier.

Design

The typical recoilless gun functions very much like a conventional gun. The projectile and propellant are supplied as a single round and loaded into the breech. When fired, however, instead of all the propellant blast following the projectile out the barrel, a large portion is allowed to escape to the rear, gaining a rearward directed momentum which is nearly equal to the forward momentum of the projectile. This balance of momenta ensure that the momentum of the rifle/projectile/exhaust gas system is conserved without imparting much momentum (recoil) to the rifle itself. Since recoil has been mostly removed, the heavy and complex gun carriage and recoil damping mechanism can be dispensed with. Despite the name, it is rare for the forces to completely balance, and real-world recoilless rifles do recoil noticeably (with varying degrees of severity). Recoilless rifles are maintenance-intensive weapons,[citation needed] and if the breech and gas ports are old, damaged, plugged or poorly maintained, the recoil-damping effect can be reduced or lost altogether, leading to dangerously powerful recoil. Conversely, if a projectile becomes lodged in the barrel for any reason, the entire weapon will recoil forward, in the manner of a rocket.

Unlike a rocket launcher, which fires fin-stabilized rockets from a smooth bore, recoilless rifle rounds resemble conventional artillery shells. They generally have a pre-engraved rifling band to engage the rifled launch tube, spin-stabilizing the projectile, hence the term "rifle". The "case" area of the shell can be perforated to vent the propellant gases which are then directed to the rear, as the base of the shell disintegrates.

Since venting hot gases to the rear can be dangerous in confined spaces, some recoilless guns such as the Armbrust and MATADOR use a combination of a countershot, smoothbore barrel and pistons to avoid both recoil and back blast. The fin stabilized Armbrust "cartridge" contains the propellant charge between two pistons with the warhead in front of one, facing forward, and an equal countermass of shredded plastic in front of the other piston. Upon firing, the propellant expands rapidly pushing the pistons outward. This pushes the projectile forwards towards the target and the countermass backwards providing the recoilless effect. The shredded plastic countermass is quickly slowed by air resistance and is harmless at a distance more than a few feet from the breech. The pistons jam at the ends of the barrel trapping the hot propellant gases inside. All this allows safe firing in enclosed spaces.

History

The first recoilless gun was developed by Commander Cleland Davis of the US Navy, just prior to the First World War. His design, named the Davis gun, connected two guns back to back, with the backwards-facing gun loaded with lead balls and grease of the same weight as the shell in the other gun. His idea was used experimentally by the British as an anti-Zeppelin and anti-submarine weapon mounted on an Handley Page O/100 bomber and intended to be installed on other aircraft.In the Soviet Union, development of recoilless weapons ("Dinamo-Reaktivnaya Pushka" (DRP), roughly "dynamic reaction cannon") began in 1923. In the 1930s many different types of weapons were built and tested with configurations ranging from 37 mm to 305 mm. Some of the smaller examples were tested in aircraft (Grigorovich I-Z and Tupolev I-12) and saw some limited production and service, but development was abandoned around 1938. The best-known of these early recoilless rifles was the Model 1935 76 mm DRP designed by Leonid Kurchevsky. A small number of these mounted on trucks saw combat in the Winter War. Two were captured by the Finns and tested; one example was given to the Germans in 1940.

The first recoilless rifle to enter service in Germany was the 7.5 cm Leichtgeschütz 40 ("light gun" '40), a simple 75 mm smoothbore recoilless gun developed to give German airborne troops artillery and anti-tank support that could be parachuted into battle. The 75 was found to be so useful during the invasion of Crete that a larger 105 mm version was developed on the same basic pattern. Interestingly both of these weapons were loosely copied by the US Army, reversing the flow of technology that had occurred when the Germans copied the Bazooka, as their own 88 mm calibre Panzerschreck infantry anti-tank rocket system. The US did have a development program and it is not clear to what extent the design was copied, as there were in fact differences. The Japanese had also developed a portable recoilless anti-tank rifle which they had reserved for the defense of the anticipated invasion of the mainland. As it was, however, these weapons remained fairly rare during the war although the US versions of the 75 started becoming increasingly common in 1945.

During the Second World War the Swedish company Bofors Carl Gustaf developed a small 20 mm device, the 20 mm m/42; the British expressed their interest in it, but by that point anti-tank rifles were already out of date.

In 1947, the US 75 mm was acquired as war surplus by the French military and mounted on a Vespa scooter. It was used by French paratroops as a mobile anti-tank and anti-fortification platform and saw service in Algeria and Indochina.

By the time of the Korean War, recoilless rifles were found throughout the US forces. The "original" US recoilless rifles were the 57mm and 75mm, followed by a 105 mm (the unsuccessful M27). Newer models replacing these were the 90 mm M67 and 106 mm M40 (which was actually 105 mm caliber but designated otherwise to prevent confusion of ammunition with the earlier model). The Soviets likewise adopted recoilless technology in the 1950s, most commonly in calibers 73 mm, 82 mm, and 107 mm .

The British, whose efforts were led by Denis Burney, inventor of the Wallbuster HESH round, also developed recoilless designs. Burney demonstrated the technique with a recoilless 4-gauge shotgun. His "Burney Gun" was developed to fire the Wallbuster shell against the Atlantic Wall defences, but was not required in the D-Day landings of 1944. He went on to produce many designs including a man-portable 3.45" (88 mm) recoilless rifle, the Ordnance, RCL, 3.45 in, pushed into experimental service in late 1945.

Two Burney guns were designed primarily as anti-tank weapons. One was 3.45 inches in calibre and could be fired off a man's shoulder or from a light tripod. The other was 3.7 inches in calibre, and was carried on a light two-wheeled mounting. The "Ordnance RCL. 3.45in MK 1" weighed 75 lb (34 kg), was 68.5in (1.74m) long, and fired an 11 lb (5 kg) wallbuster shell to 1,000 yards. No penetration figures were ever made public. but it is fairly certain that it could knock a 10 lb slab off the back of 6 in (150 mm ) of armour plate at any range it could hit. The 3.7 was a larger weapon weighing 222 lb (100 kg); it was 112 in (2.84 m) long and fired a 22.2 lb (10 kg) wallbuster to 2,000 yards; it is estimated that this could have dealt successfully with armour up to 10 in (254 mm) thick. Post-war work developed and deployed the BAT series of recoilless rifles, culminating in the 120 mm L6 Wombat ("Weapon of Magnesium, Battalion Anti-tank"). This was too large to be transported by infantry, and was usually towed by jeep. The weapon was aimed via a spotting rifle, which fired .50 BMG rounds whose trajectory matched that of the main weapon. Tracer rounds were fired first until hits were observed before firing off the main gun.

Lightweight SPG-9 73 mm and B10 82 mm heavy recoilless rifles are still in service in the Russian army in airborne units, and are found quite commonly around the world in the inventories of former Soviet client states, where they are usually used as antitank guns.

During the 1960s and 1970s, wire-guided missiles began to supplant recoilless rifles in the anti-tank role. The recoilless rifle started to disappear from the military except in areas such as the Arctic where battery-powered Dragons and wire-guided TOWs would fail due to extreme low temperatures. The former 6th Light Infantry Division in Alaska used the M67 in its special weapons platoons, as did the Ranger Battalions and the US Army's Berlin Brigade. The last major use was the M50 Ontos, which mounted six of the US 106 mm on a light (9 ton) tracked chassis first developed for use by the US Army airborne troops in 1950. However the Army considered them useless, and the Marines adopted the vehicle in a limited role. They used them to great effect as an anti-personnel fire support vehicle during the Vietnam War. The crews continued to report that the Ontos was a very effective fighting vehicle in this role, but the military brass continued to argue for heavier designs, and in 1970 the Ontos was removed from service and most were broken up. However the recoilless rifle found other roles, most notably in the India-Pakistan confrontation in Kashmir, where it was used against bunkers and as artillery in otherwise inhospitable terrain.

The Viet Minh also developed their own recoilless rifle under the direction of Tran Dai Nghia. The Vietnamese version was named SKZ or Sung khong giat (a Vietnamese translation of "recoilless rifle") and was used intensively in assaulting the French bunkers and fortified positions. The larger version of SKZ was DKZ or Phao khong giat ("recoilless artillery").

Today one of several remaining front-line recoilless rifles in the armies of industrialized nations is the famous Carl Gustav recoilless rifle, an 84 mm man-portable anti-tank weapon. First introduced in 1946, it is still in widespread use throughout the world today, and has even been re-introduced into the US Marine Corps as an anti-bunker weapon. The 84 mm (Carl Gustav recoilless rifle) can be used, along with 66 mm (AKA M72 LAW) and LAW 80 for mouse-holing whilst fighting in built-up areas (FIBUA). This is where impromptu "doors" are added to a building to gain entry, hopefully avoiding the prepared defences of the occupiers. Many nations also use a weapon related to the Carl Gustav, the one-shot AT-4 recoilless weapon.

Another recoilless rifle still in use is the Italian-made 80 mm Breda Folgore, which was introduced in 1986 and built up to 2001. It is available in a shoulder-launched and in a tripod-mounted version. The use of boost-after-launch rocked-propelled projectiles gives the weapon a long effective range, compared to similar weapons.

The US-made, M40 106 mm recoilless rifles, usually mounted on jeeps or similar small vehicles, are very common in the armies of many countries, where they serve in the role of tank destroyers.

Deployed by the United States in the 1960s, the Davy Crockett used a recoilless smooth bore gun to launch a tactical nuclear warhead.

Civilian use

U.S. Forest Service team using a 106 mm Recoilless Rifle for avalanche control at Mammoth Mountain in the Inyo National Forest. Note Minarets in background.

No comments:

Post a Comment