From Wikipedia, the free encyclopedia

A vibrating structure gyroscope or "Coriolis Vibratory Gyroscope (CVG)" (as specified in IEEE Standard) [1] is a wide group of gyroscope using solid-state resonators of different shapes that functions much like the halteres of an insect. The underlying physical principle is that a vibrating object tends to continue vibrating in the same plane as its support rotates. In the engineering literature, this type of device is also known as a Coriolis vibratory gyro because as the plane of oscillation is rotated, the response detected by the transducer results from the Coriolis term in its equations of motion ("Coriolis force").Vibrating structure gyroscopes are simpler and cheaper than conventional rotating gyroscopes of similar accuracy. Miniaturized devices using this principle are a relatively inexpensive type of attitude indicator.

Theory of Operation

Consider two proof masses vibrating in plane (as in the MEMS gyro) at frequency . Recall that the Coriolis effect induces an acceleration on the proof masses equal to

. Recall that the Coriolis effect induces an acceleration on the proof masses equal to  , where

, where  is a velocity and

is a velocity and  is an angular rate of rotation. The in-plane velocity of the proof masses is given by:

is an angular rate of rotation. The in-plane velocity of the proof masses is given by:  , if the in-plane position is given by

, if the in-plane position is given by  . The out-of-plane motion

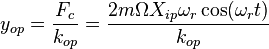

. The out-of-plane motion  , induced by rotation, is given by:

, induced by rotation, is given by: is a mass of the proof mass,

is a mass of the proof mass, is a spring constant in the out of plane direction,

is a spring constant in the out of plane direction, is a magnitude of a rotation vector in the plane of and perpendicular to the driven proof mass motion.

is a magnitude of a rotation vector in the plane of and perpendicular to the driven proof mass motion.

If we consider a polarization of a shear (transverse) elastic wave propagating along an acoustic axis in a solid—a polarization rotation effect from rotation of the body as a whole (the polarization inertia effect) can be observed too. (It was noted by Ukrainian scientist Sergii A. Sarapuloff in the early 1980s,[3] It also produces a corresponding modification of Green-Christoffel's tensors in Acoustics[4][5]).

Implementations

Piezoelectric Gyroscopes

A piezoelectric material can be induced to vibrate, and lateral motion due to centrifugal force can be measured to produce a signal related to the rate of rotation.[6]Wine-Glass Resonator

Also called a Hemispherical Resonator Gyroscope or HRG, a wine-glass resonator makes using a thin solid-state hemisphere, anchored by a thick stem, and driven to a flexural resonance of this shell, the nodal points of which are measured to detect rotation. There are two basic variants of such a system: one based on a rate regime of operation (so-called, "force-to-rebalance mode") and another variant based on an integrating regime of operation (so-called, "whole-angle mode"). Usually, the latter one is used in combination with a controlled parametric excitation. It is possible to use the both regimes with same hardware, which is a feature unique to these gyroscopes. For a single-piece design (i.e., the hemispherical cup and stem(s) form a monolithic part) made from high-purity quartz glass, it is possible to reach Q-factor over 30-50 millions in vacuum, so, the corresponding random walks are extremely low. The Q is limited by coating (extremely thin film of gold or platinum) and by fixture losses.[7] Such resonators have to be fine-tuned by ion-beam micro-erosion of the glass or by laser ablation. Engineers and researchers in several countries have been working on further improvements of these sophisticated state-of-art technologies.[8]Cylindrical Resonator Gyroscope (CRG)

This type of gyroscope was developed by GE Marconi and GE Ferranti in 80s using alloys with attached piezoelectri elements and single-piece piezoceramic design, then, in 90s, CRGs with magneto-electric excitation and readout were produced by Inertial Engineering, Inc. (CA, USA), and piezo-ceramic variants by Watson Industries, and a recently patented variant by Innalabs uses cylindrical design resonator made from Elinvar-type alloy with piezoceramic elements for excitation and pickoff at its perforated bottom. This breakthrough technologies allowed substantially increase product life of the gyroscopes (MTBF > 500,000 hours) and their shock resistance (>300g) that looks enough for "tactical" (mid-accuracy) applications. The resonator is operated on its second order resonant modes. The Q-factor is usually about 20,000 that pre-determine its noises and angle random walks. Standing waves are therefore elliptical shape oscillations with four antinodes and four nodes located circumferentially along the rim, angle between two adjacent antinode – node being 45 deg. One of the elliptical resonant modes is excited to a prescribed amplitude. When the device rotates about its sensitive axis (along its inner stem), the resulting Coriolis forces acting on the resonator’s vibrating mass elements excite the second resonant mode. Angle between major axis of the two modes is 45 deg. A closed-loop drives the second resonant mode to zero and the force required to null this mode is proportional to the input rotation rate. Corresponding control loop system is called force-rebalanced mode. Piezo-electric elements on the resonator produce forces and sense induced motions. This electromechanical system provides the low output noise and large dynamic range that demanding applications require, but suffers from intense acoustic noises and high overloads.Tuning Fork Gyroscope

This type of gyroscope uses a pair of test masses driven to resonance. Their displacement from the plane of oscillation is measured to produce a signal related to the system's rate of rotation.F.W. Meredith registered a patent for such a device in 1942 while working at the Royal Aircraft Establishment. Further development was carried out at the RAE in the late 1950s by G.H. Hunt and A.E.W. Hobbs, who demonstrated drift of less than 1 °/h (3.6×10−4 °/s).[9]

Modern variants of tactical gyros use doubled tuning forks such as those produced by Systron Donner (CA, USA) and SAGEM Défence Securité / Safran Group (France).[10]

Vibrating wheel gyroscope

A wheel is driven to rotate a fraction of a full turn about its axis. The tilt of the wheel is measured to produce a signal related to the rate of rotation.[11]MEMS Gyroscopes

Inexpensive vibrating structure gyroscopes manufactured with MEMS technology have become widely available. These are packaged similarly to other integrated circuits and may provide either analog or digital outputs. In many cases, a single part includes gyroscopic sensors for multiple axes. Some parts incorporate multiple gyroscopes and accelerometers (or multiple axis gyroscopes and accelerometers, to achieve output that has six full degrees of freedom. These units are called Inertial measurement units, or IMUs. Panasonic, Robert Bosch GmbH, InvenSense, Seiko Epson, Sensonor, STMicroelectronics, and Analog Devices are major manufacturers.Internally, MEMS gyroscopes use lithographically constructed versions of one or more of the mechanisms outlined above (tuning forks, vibrating wheels, or resonant solids of various designs, i.e., similar to TFG, CRG, or HRG mentioned above).[12]

No comments:

Post a Comment