From Wikipedia, the free encyclopedia

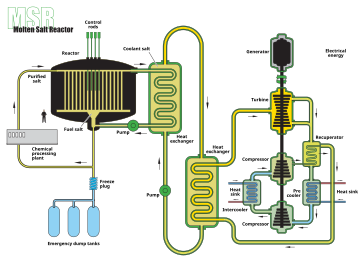

A molten salt reactor (MSR) is a class of nuclear fission reactors in which the primary coolant, or even the fuel itself, is a molten salt mixture. MSRs run at higher temperatures than water-cooled reactors for higher thermodynamic efficiency, while staying at low vapor pressure.The nuclear fuel may be solid or dissolved in the coolant itself. In many designs the nuclear fuel is dissolved in the molten fluoride salt coolant as uranium tetrafluoride (UF4). The fluid becomes critical in a graphite core which serves as the moderator. Solid fuel designs rely on ceramic fuel dispersed in a graphite matrix, with the molten salt providing low pressure, high temperature cooling. The salts are much more efficient than compressed Helium at removing heat from the core, reducing the need for pumping, piping and reducing the size of the core.

The early Aircraft Reactor Experiment (1954) was primarily motivated by the small size that the design could provide, while the Molten-Salt Reactor Experiment (1965–1969) was a prototype for a thorium fuel cycle breeder reactor nuclear power plant. One of the Generation IV reactor designs is a molten salt-cooled, solid-fuel reactor[not in citation given]; the initial reference design is 1000 MWe.[1]

Contents

History

Aircraft reactor experiment

Main article: Aircraft Reactor Experiment

Extensive research into molten salt reactors started with the U.S. aircraft reactor experiment (ARE) in support of the U.S. Aircraft Nuclear Propulsion program. The ARE was a 2.5 MWth

nuclear reactor experiment designed to attain a high power density for

use as an engine in a nuclear-powered bomber. The project included

several reactor experiments including high temperature reactor and

engine tests collectively called the Heat Transfer Reactor Experiments:

HTRE-1, HTRE-2 and HTRE-3 at the National Reactor Test Station (now Idaho National Laboratory)

as well as an experimental high-temperature molten salt reactor at Oak

Ridge National Laboratory - the ARE. The ARE used molten fluoride salt

NaF-ZrF4-UF4 (53-41-6 mol%) as fuel, was moderated by beryllium oxide

(BeO), used liquid sodium as a secondary coolant and had a peak

temperature of 860 °C. It operated for 100 MW-hours over nine days in

1954. This experiment used Inconel 600 alloy for the metal structure and piping.[2]Molten-salt reactor experiment

Main article: Molten-Salt Reactor Experiment

Oak Ridge National Laboratory (ORNL) took the lead in researching the MSR through 1960s, and much of their work culminated with the Molten-Salt Reactor Experiment (MSRE). The MSRE was a 7.4 MWth test reactor simulating the neutronic "kernel" of a type of epithermal thorium molten salt breeder reactor called the Liquid fluoride thorium reactor. The large, expensive breeding blanket of thorium salt was omitted in favor of neutron measurements.The MSRE was located at ORNL. Its piping, core vat and structural components were made from Hastelloy-N and its moderator was pyrolytic graphite. It went critical in 1965 and ran for four years. The fuel for the MSRE was LiF-BeF2-ZrF4-UF4 (65-29-5-1), the graphite core moderated it, and its secondary coolant was FLiBe (2LiF-BeF2). It reached temperatures as high as 650 °C and operated for the equivalent of about 1.5 years of full power operation.

Oak Ridge National Laboratory molten salt breeder reactor

The culmination of the Oak Ridge National Laboratory research during the 1970–1976 timeframe resulted in a proposed molten salt breeder reactor (MSBR) design which would use LiF-BeF2-ThF4-UF4 (72-16-12-0.4) as fuel, was to be moderated by graphite with a 4-year replacement schedule, use NaF-NaBF4 as the secondary coolant, and have a peak operating temperature of 705 °C.[3] Despite the success, the MSR program closed down in the early 1970s in favor of the liquid metal fast-breeder reactor (LMFBR),[4] after which research stagnated in the United States.[5][6] As of 2011, the ARE and the MSRE remained the only molten-salt reactors ever operated.The MSBR project received funding until 1976. Inflation-adjusted to 1991 dollars, the project received $38.9 million from 1968 to 1976.[7]

The following reasons were cited as responsible for the program cancellation:

- The political and technical support for the program in the United States was too thin geographically. Within the United States, only in Oak Ridge, Tennessee, was the technology well understood.[4]

- The MSR program was in competition with the fast breeder program at the time, which got an early start and had copious government development funds being spent in many parts of the United States. When the MSR development program had progressed far enough to justify a greatly expanded program leading to commercial development, the AEC could not justify the diversion of substantial funds from the LMFBR to a competing program.[4]

Russian MSR research program

In Russia, a molten-salt reactor research program was started in the second half of the 1970s at the Kurchatov Institute. It covered a wide range of theoretical and experimental studies, particularly the investigation of mechanical, corrosion and radiation properties of the molten salt container materials. The main findings of completed program supported the conclusion that there are no physical nor technological obstacles to the practical implementation of MSRs.[8] A reduction in activity occurred after 1986 due to the Chernobyl disaster, along with a general stagnation of nuclear power and nuclear industry.[9](p381)Recent developments

Liquid-salt very-high-temperature reactor

Main article: Very high temperature reactor

As of September 2010, research was continuing for reactors that utilize molten salts for coolant. Both the traditional molten-salt reactor and the very high temperature reactor (VHTR) were selected as potential designs for study under the Generation Four Initiative (GEN-IV). A version of the VHTR being studied was the liquid-salt very-high-temperature reactor (LS-VHTR), also commonly called the advanced high-temperature reactor (AHTR).[citation needed]

It is essentially a standard VHTR design that uses liquid salt as a

coolant in the primary loop, rather than a single helium loop. It relies

on "TRISO"

fuel dispersed in graphite. Early AHTR research focused on graphite

would be in the form of graphite rods that would be inserted in

hexagonal moderating graphite blocks, but current studies focus

primarily on pebble-type fuel.[citation needed]

The LS-VHTR has many attractive features, including: the ability to

work at very high temperatures (the boiling point of most molten salts

being considered are >1400 °C); low-pressure cooling that can be used

to more easily match hydrogen production facility conditions (most thermochemical cycles

require temperatures in excess of 750 °C); better electric conversion

efficiency than a helium-cooled VHTR operating at similar conditions; passive safety systems, and better retention of fission products in the event of an accident.[citation needed] This concept is now referred to as "fluoride salt-cooled high-temperature reactor" (FHR).[10]Liquid fluoride thorium reactor

Main article: Liquid fluoride thorium reactor

Reactors containing molten thorium salt, called liquid fluoride

thorium reactors (LFTR), would tap the abundant energy source of the thorium fuel cycle.

Private companies from Japan, Russia, Australia and the United States,

and the Chinese government, have expressed interest in developing this

technology.[11][12][13]Advocates estimate that five hundred metric tons of thorium could supply all U.S. energy needs for one year.[14] The U.S. Geological Survey estimates that the largest known U.S. thorium deposit, the Lemhi Pass district on the Montana-Idaho border, contains thorium reserves of 64,000 metric tons of thorium.[15]

Fuji reactor

The FUJI MSR is a 100 to 200 MWe LFTR, using technology similar to the Oak Ridge National Laboratory Reactor. It is being developed by a consortium including members from Japan, the U.S. and Russia. It would likely take 20 years to develop a full size reactor[16] but the project seems to lack funding.[11]Chinese project

Under the direction of Jiang Mianheng, The People’s Republic of China has initiated a research project in thorium molten-salt reactor technology. It was formally announced at the Chinese Academy of Sciences (CAS) annual conference in January 2011. The plan was "to build a tiny 2 MW plant using liquid fluoride fuel by the end of the decade, before scaling up to commercially viable size over the 2020s. It is also working on a pebble-bed reactor."[13][17] The proposed completion date for a test 2 MW pebble-bed solid thorium and molten salt cooled reactor has been delayed from 2015 to 2017. The proposed "test thorium molten-salt reactor" has also been delayed.[18]Indian research

Ratan Kumar Sinha, Chairman of Atomic Energy Commission of India, stated in 2013: "India is also investigating Molten Salt Reactor (MSR) technology. We have molten salt loops operational at BARC."[19]U.S. companies

Kirk Sorensen, former NASA scientist and chief nuclear technologist at Teledyne Brown Engineering, has been a long-time promoter of the thorium fuel cycle, coining the term liquid fluoride thorium reactor. In 2011, Sorensen founded Flibe Energy, a company aimed at developing 20-50 MW LFTR reactor designs to power military bases. (It is easier to approve novel military designs than civilian power station designs in today's US nuclear regulatory environment).[12][20][21][22]Another startup company, Transatomic Power, has been created by Ph.D. students from MIT and Russ Wilcox of E Ink.[23] They are pursuing what they term a Waste-Annihilating Molten Salt Reactor, focused on the potential to consume existing nuclear waste more thoroughly.[24][25]

Weinberg Foundation

The Weinberg Foundation is a British non-profit organization founded in 2011, dedicated to act as a communications, debate and lobbying hub to raise awareness about the potential of thorium energy and LFTR. It was formally launched at the House of Lords on 8 September 2011.[26][27][28] It is named after American nuclear physicist Alvin M. Weinberg, who pioneered the thorium molten salt reactor research.Molten-salt fueling options

- The thorium-fueled variant called Liquid fluoride thorium reactor, has been very exciting to many nuclear engineers. Its most prominent champion was Alvin Weinberg, who patented the light-water reactor and was a director of the U.S.'s Oak Ridge National Laboratory, a prominent nuclear research center.

- MSR can be fueled using enriched Uranium-235.

- MSR can be fueled using fissile material from dismantled nuclear weapons.[29]

Molten-salt-cooled reactors

Molten-salt-fueled reactors are quite different from molten-salt-cooled solid-fuel reactors, called simply "molten salt reactor system" in the Generation IV proposal, also called MSCR, which is also the acronym for the Molten Salt Converter Reactor design. These reactors were additionally referred to as "advanced high-temperature reactors (AHTRs), but since about 2010 the preferred DOE designation is "fluoride high-temperature reactors (FHRs)".[30]The FHR concept cannot reprocess fuel easily and has fuel rods that need to be fabricated and validated, delaying deployment by up to twenty years[citation needed] from project inception. However, since it uses fabricated fuel, reactor manufacturers can still profit by selling fuel assemblies.

The FHR retains the safety and cost advantages of a low-pressure, high-temperature coolant, also shared by liquid metal cooled reactors. Notably, there is no steam in the core to cause an explosion, and no large, expensive steel pressure vessel. Since it can operate at high temperatures, the conversion of the heat to electricity can also use an efficient, lightweight Brayton cycle gas turbine.

Much of the current research on FHRs is focused on small compact heat exchangers. By using smaller heat exchangers, less molten salt needs to be used and therefore significant cost savings could be achieved.[31]

Molten salts can be highly corrosive, more so as temperatures rise. For the primary cooling loop of the MSR, a material is needed that can withstand corrosion at high temperatures and intense radiation. Experiments show that Hastelloy-N and similar alloys are quite suited to the tasks at operating temperatures up to about 700 °C. However, long-term experience with a production scale reactor has yet to be gained. In spite of serious engineering difficulties higher operating temperatures may be desirable - at 850 °C thermochemical production of hydrogen becomes possible. Materials for this temperature range have not been validated, though carbon composites, molybdenum alloys (e.g. TZM), carbides, and refractory metal based or ODS alloys might be feasible.

Fused salt selection

The salt mixtures are chosen to make the reactor safer and more practical. Fluoride salts are favored, because fluorine has only one stable isotope (F-19), and it does not easily become radioactive under neutron bombardment. Both of these make fluorine better than chlorine, which has two stable isotopes (Cl-35 and Cl-37), as well as a slow-decaying isotope between them which facilitates neutron absorption by Cl-35. Compared to chlorine and other halides, fluorine also absorbs fewer neutrons and slows ("moderates") neutrons better. Low-valence fluorides boil at high temperatures, though many pentafluorides and hexafluorides boil at low temperatures. They also must be very hot before they break down into their simpler components, such molten salts are "chemically stable" when maintained well below their boiling points.On the other hand, some salts are so useful that isotope separation of the halide is worthwhile. Chlorides permit fast breeder reactors to be constructed using molten salts. However, not nearly as much work has been done on reactor designs using chloride salts. Chlorine, unlike fluorine, must be purified to isolate the heavier stable isotope, chlorine-37, thus reducing production of sulfur tetrafluoride that occurs when chlorine-35 absorbs a neutron to become chlorine-36, then degrades by beta decay to sulfur-36. Similarly, any lithium present in a salt mixture must be in the form of purified lithium-7 to reduce tritium production by lithium-6 (the tritium then forms corrosive hydrogen fluoride).

Reactor salts are usually close to eutectic mixtures to reduce their melting point. A low melting point simplifies melting the salt at startup and reduces the risk of the salt freezing as it's cooled in the heat exchanger.

Due to the high "redox window" of fused fluoride salts, the chemical potential of the fused salt system can be changed. Fluorine-Lithium-Beryllium ("FLiBe") can be used with beryllium additions to lower the electrochemical potential and almost eliminate corrosion. However, since beryllium is extremely toxic, special precautions must be engineered into the design to prevent its release into the environment. Many other salts can cause plumbing corrosion, especially if the reactor is hot enough to make highly reactive hydrogen.

To date, most research has focused on FLiBe, because lithium and beryllium are reasonably effective moderators, and form a eutectic salt mixture with a lower melting point than each of the constituent salts. Beryllium also performs neutron doubling, improving the neutron economy. This process occurs when the Beryllium nucleus re-emits two neutrons after absorbing a single neutron. For the fuel carrying salts, generally 1% or 2% (by mole) of UF4 is added. Thorium and plutonium fluorides have also been used.

Fused salt purification

Techniques for preparing and handling molten salt had been first developed at Oak Ridge National Lab.[33] The purpose of salt purification was to eliminate oxides, Sulfur, and metal impurities. Oxides could result in the deposition of solid particles in reactor operation. Sulfur had to be removed because of their corrosive attack on nickel-base alloys at operational temperature. Structural metal such as Chromium, Nickel, and Iron had to be removed for corrosion control.A water content reduction purification stage using HF and Helium sweep gas was specified to run at 400 °C. Oxide and Sulfur contamination in the salt mixtures were removed using gas sparging of HF - H2 mixture, with the salt heated to 600 °C.[33](p8) Structural metal contamination in the salt mixtures were removed using Hydrogen gas sparging, at 700 °C.[33](p26) Solid ammonium hydrofluoride was proposed as a safer alternative for oxide removal.[34]

Fused salt processing

The possibility of online processing can be an advantage of the MSR design. Continuous processing would reduce the inventory of fission products, control corrosion and improve neutron economy by removing fission products with high neutron absorption cross-section, especially xenon. This makes the MSR particularly suited to the neutron-poor thorium fuel cycle. Online fuel processing can introduce risks of fuel processing accidents[35](p15), which can trigger release of radio isotopes.In some thorium breeding scenarios, the intermediate product protactinium-233 would be removed from the reactor and allowed to decay into highly pure uranium-233, an attractive bomb-making material. More modern designs propose to use a lower specific power or a separate large thorium breeding blanket. This dilutes the protactinium to such an extent that few protactinium atoms absorb a second neutron or, via a (n, 2n) reaction (in which an incident neutron is not absorbed but instead knocks a neutron out of the nucleus), generate uranium-232. Because U-232 has a short half-life and its decay chain contains hard gamma emitters, it makes the isotopic mix of uranium less attractive for bomb-making. This benefit would come with the added expense of a larger fissile inventory or a 2-fluid design with a large quantity of blanket salt.

The necessary fuel salt reprocessing technology has been demonstrated, but only at laboratory scale. A prerequisite to full-scale commercial reactor design is the R&D to engineer an economically competitive fuel salt cleaning system.

Fissile fuel reprocessing issues

Reprocessing refers to the chemical separation of fissionable uranium and plutonium from spent nuclear fuel.[36] The recovery of uranium or plutonium could be subject to the risk of nuclear proliferation. In the United States the regulatory regime has varied dramatically in different administrations.[36]In the original 1971 Molten Salt Breeder Reactor proposal, uranium reprocessing was scheduled every ten days as part of reactor operation.[37](p181) Subsequently a once-through fueling design was proposed that limited uranium reprocessing to every thirty years at the end of useful salt life.[38](p98) A mixture of uranium-238 was called for to make sure recovered uranium would not be weapons grade. This design is referred to as denatured molten salt reactor.[39] If reprocessing were to be prohibited then the uranium would be disposed with other fission products.

Comparison to ordinary light water reactors

MSRs, especially those with the fuel dissolved in the salt differ considerably from conventional reactors. The pressure can be low and the temperature is much higher. In this respect an MSR is more similar to a liquid metal cooled reactor than a conventional light water cooled reactor. As an additional difference MSRs are often planned as breeding reactor with a closed fuel cycle - as opposed to using a once-through fuel currently used in US nuclear reactors.The typical safety concepts rely on a negative temperature coefficient of reactivity and a large possible temperature rise to limit reactivity excursions. As an additional method for shutdown a separate, passively cooled container below the reactor is planned. In case of problems and for regular maintenance the fuel is drained from the reactor. This stops the nuclear reaction and gives a second cooling system. Neutron-producing accelerators have even been proposed for some super-safe subcritical experimental designs.[40]

Cost estimates from the 1970s were slightly lower than for conventional light-water reactors.[41]

The temperatures of some proposed designs are high enough to produce process heat for hydrogen production or other chemical reactions. Because of this, they have been included in the GEN-IV roadmap for further study.[42]

Advantages

The molten salt reactor offers many potential advantages compared to current light water reactors:[3]- Inherently safe design (safety by passive components and the strong negative temperature coefficient of reactivity of some designs).

- Operating at a low pressure improves safety and simplifies the design

- In theory a full recycle system can be much cleaner: the discharge wastes after chemical separation are predominately fission products, most of which have relatively short half lives compared to longer-lived actinide wastes. This can result in a significant reduction in the containment period in a geologic repository (300 years vs. tens of thousands of years).

- The fuel's liquid phase is adequate for pyroprocessing for separation of fission products. This may have advantages over conventional reprocessing, though much development is still needed.

- There is no need for fuel rod manufacturing

- Some designs can "burn" problematic transuranic elements from traditional solid-fuel nuclear reactors.

- An MSR can react to load changes in less than 60 seconds (unlike "traditional" solid-fuel nuclear power plants that suffer from Xenon poisoning).

- Molten salt reactors can run at high temperatures, yielding high efficiencies to produce electricity.

- Some MSRs can offer a high "specific power", that is high power at a low mass. This was demonstrated by the ARE, the aircraft reactor experiment.[2]

- a possibly good neutron economy makes the MSR attractive for the neutron poor thorium fuel cycle.

- LWR's (and most other solid-fuel reactors) have no clean "off switch", but once the initial criticality is overcome an MSR is comparatively easy and fast to turn on and off. For example, it is said that the researchers would "turn off the Molten-Salt Reactor Experiment for the weekend". At a minimum, the reactor needs enough energy to re-melt the salt and engage the pumps.

Disadvantages

- Little development compared to most Gen IV designs - much is unknown.

- Need to operate an on-site chemical plant to manage core mixture and remove fission products.

- Lithium containing salts will cause significant tritium production (comparable with heavy water reactors), even if pure 7Li is used. Tritium itself is valuable, but also decays (half-life 12.32 yrs) to helium-3, another valuable product.

- Likely need for regulatory changes to deal with radically different design features.

- Corrosion may occur over many decades of reactor operation and could be problematic.[43]

- Nickel and iron based alloys are prone to embrittlement under high neutron flux.[38](p83)

- Being a breeder reactor, it may be possible to modify an MSR to produce weapons grade nuclear material.[44]

No comments:

Post a Comment