From Wikipedia, the free encyclopedia

Small reactors are defined by the International Atomic Energy Agency as those with an electricity output of less than 300 MWe, although general opinion is that anything with an output of less than 500 MWe counts as a small reactor.[1][2]

Modular reactors are manufactured at a plant and brought to the site fully constructed. They allow for less on-site construction, increased containment efficiency, and heightened nuclear materials security.

Contents

- 1 History

- 2 Operation

- 3 Innovations

- 4 Reactor designs

- 4.1 CAREM: Argentina

- 4.2 Encapsulated Nuclear Heat Source (ENHS): United States

- 4.3 Flibe Energy: United States

- 4.4 Hyperion Power Module (HPM): United States

- 4.5 International Reactor Innovative & Secure (IRIS): United States

- 4.6 Modified KLT-40: Russia

- 4.7 mPower: United States

- 4.8 NuScale: United States

- 4.9 Pebble Bed Modular Reactor (PBMR): South Africa

- 4.10 Purdue Novel Modular Reactor (PNMR): United States

- 4.11 Remote Site-Modular Helium Reactor (RS-MHR): United States

- 4.12 Super Safe, Small & Simple (4S): Japan

- 4.13 Traveling Wave Reactor (TWR): United States

- 4.14 Westinghouse SMR

- 5 Licensing Concerns

- 6 References

- 7 Further reading

- 8 External links

History

Electricity was first generated from nuclear energy on December 20, 1951 in the high desert of south-eastern Idaho. The original electrical output was estimated at 45 kW.[3] Since then, reactors have grown much larger, with electrical outputs of over 1,400 MW.[4] Almost 50 years after the first nuclear energy was generated, applications for reactors with low electrical outputs are being introduced again.According to a report prepared by Oak Ridge National Laboratory, the long-term goal of nuclear power is to “develop an economic, safe, environmentally acceptable, unlimited supply of energy for society.”[5]

Remote locations often have difficulty finding economically efficient, reliable energy sources. Small nuclear reactors have been considered as solutions to many energy problems in these hard-to-reach places.

Many of these smaller reactor designs are being made “modular” – in other words, they will be manufactured and assembled at a central factory location. They are then sent to their new location where they can be installed with very little difficulty. These SMRs are particularly useful in remote locations where there is usually a deficiency of trained workers and a higher cost of shipping. Containment is more efficient, and proliferation concerns are lessened.[6] SMRs are also more flexible in that they do not necessarily need to be hooked into a large power grid, and can generally be attached to other modules to provide increased power supplies if necessary.

There may be some economic benefits to SMRs as well. While the small power output of an SMR means that electricity will cost more per MW than it would from a larger reactor, the initial cost of building the plant is much less than that of constructing a much more complex, non-modular, large nuclear plant. It makes an SMR a smaller-risk venture for power companies than other nuclear power plants.[7]

SMRs produce anywhere from ten to 300 megawatts, rather than the 1,000 megawatts produced by a typical reactor. Safety features include a natural cooling feature that can continue to function in the absence of external power; which was precisely the problem that was faced in Japan when the 2011 tsunami hit. The SMR also has the advantage of having underground placement of the reactors and spent-fuel storage pools, which provides more security. Smaller reactors would be easier to upgrade quickly, require a permanent workforce, and have better quality controls, just to name a few more advantages.[8]

Operation

There are a variety of different types of SMR. Some are simplified versions of current reactors, others involve entirely new technologies.[9]Fission and reactivity control

Nuclear power plants generate heat through nuclear fission. When an unstable nucleus (such as 235U) absorbs an extra neutron, the atom will split, releasing large quantities of energy in the form of heat and radiation. The split atom will also release neutrons, which can then be absorbed by other unstable nuclei, causing a chain reaction. A sustained fission chain is necessary to generate nuclear power.There are certain conditions that must be met for this chain reaction to occur. Certain fuel densities are necessary, or the neutrons won't impact new atoms. It is also easier for unstable nuclei to absorb neutrons when the neutrons are travelling at a certain speed. For 235U, slower neutrons are more likely to cause a fission reaction. In order to slow down the neutrons in a reactor core, a moderator is used. Water is the most common moderator in use today. The neutrons are slowed down as they travel through the water. As the reaction speeds up and the temperature of the reactor increases, increasing the temperature of the moderator, the neutrons aren’t slowed down as effectively. This in turn reduces the rate of nuclear reactions inside the core, since the faster neutrons aren’t as easy to absorb. This effect, the negative temperature coefficient, makes the reactor inherently resistant to “excursion”, or a sudden, uncontrolled increase in temperature.[10]

Many SMRs are “fast reactors” – they don’t use moderators to slow down the neutrons. The fuel requirements in this kind of reactor are a little different. The atoms have to absorb neutrons travelling at higher speeds. This usually means changing the fuel arrangement within the core, or using different fuel types. 239Pu is more likely to absorb a high-speed neutron than 235U would be. However, the same negative temperature coefficient comes into play with fast nuclear reactors. Once the core heats up too much and the neutrons start to move faster, even the elements that would usually be able to absorb neutrons have trouble capturing them. Fission slows, and the reactor cannot run out of control.[11]

Another benefit of these fast reactors is that some of them are breeder reactors. As these reactors produce energy, they also let off enough neutrons to transmute non-fissionable elements into fissionable ones. A very common use for a breeder reactor is to surround the core in a “blanket” of 238U, which is the most easily found isotope of uranium. Once the 238U undergoes a neutron absorption reaction, it becomes 239Pu, which can be removed from the reactor once it is time to refuel, and used as more fuel once it has been cleaned.[12]

Coolant

Currently, most reactors use water as a coolant. Light water (H2O) is more common than heavy water (D

2O). New reactor designs are experimenting with different coolant types. Liquid metal reactors have been used both in the U.S. and other countries for some time. Gas-cooled reactors and Molten salt reactors are also being looked at as an option for very high temperature operation.[13][14]

Thermal/electrical generation

Traditionally, nuclear reactors use a coolant loop to heat water into steam, and use that steam to run turbines to generate electricity. There are some of the new gas-cooled reactor designs that are meant to drive a gas-powered turbine, rather than using a secondary water system. Also, there are some plants now that are used for their ability to generate thermal, rather than electric, energy. Nuclear reactor heat can be used in hydrogen production and myriad commercial operations.[13] Right now some of the possible nuclear heat applications include water desalination, heat for the production of petroleum products (extracting oil from tar sands, creating synthetic oil from coal, etc.), and the production of hydrogen for use in anything from car batteries to nitrogen fertilizers.[15]Innovations

The electricity needs in remote locations are usually small and highly variable.[16] Large nuclear power plants are generally rather inflexible in their power generation capabilities. SMRs have a load-following design so that when electricity demands are low they will produce a lower amount of electricity.Many SMRs are designed to use new fuel ideas that allow for higher burnup rates and longer lifecycles. Longer refueling intervals can decrease proliferation risks and lower chances of radiation escaping containment. For reactors in remote areas, accessibility can be troublesome, so longer fuel life can be very helpful.

Because of the lack of trained personnel available in remote areas, SMRs have to be inherently safe. Many larger plants have active safety features that require “intelligent input,” or human controls. Many of these SMRs are being made using passive safety features and inherent safety features. Passive safety features are engineered, but do not require outside input to work. A pressure release valve may have a spring that can be pushed back when the pressure gets too high. Inherent safety features require no engineered, moveable parts to work. They only depend on physical laws.[17]

Safety features

Since there are several different ideas for SMRs, there are many different safety features that can be involved. Coolant systems can use natural circulation – convection – so there are no pumps, no moving parts that could break down, and they keep removing decay heat after the reactor shuts down, so that the core doesn’t overheat and melt. Negative temperature coefficients in the moderators and the fuels keep the fission reactions under control, causing the fission reactions to slow down as temperature increases.[18]Staffing

Several SMR developers are claiming that their designs will require fewer staff members to run the reactors because of the increased inherent and passive safety systems. Some of the reactors, like the Toshiba 4S, are reportedly designed to run with little supervision.[19]Waste reduction

Many SMRs are fast reactors that are designed to have higher fuel burnup rates, reducing the amount of waste produced. At higher neutron energy more fission products can be usually tolerated. As mentioned before, some SMRs are also breeder reactors, which not only “burn” fuels like 235U, but will also convert fissionable materials like 238U (which occurs naturally at a much higher concentration than 235U) into usable fuels.[12]Some reactors are designed to run on alternative thorium fuel cycle, which offers significantly reduced long-term waste radiotoxicity compared to uranium cycle.[20]

There has been some interest in the concept of a traveling wave reactor, a new type of breeder reactor that uses the fuel it breeds. The idea would eliminate the need to remove the spent fuel and “clean” it before reusing any newly bred fuel.[21]

Non-proliferation

The use of nuclear materials to create weapons is always a concern. Many SMRs are designed to lessen the danger of materials being stolen or misplaced. Nuclear reactor fuel is low-enriched uranium, or has a concentration of less than 20% 235U. This low quantity, non-weapons-grade uranium makes the fuel less desirable for weapons production. Once the fuel has been irradiated, the fission products mixed with the fissile materials are highly radioactive and require special handling to remove safely, another non-proliferation feature.Reactors designed to run on alternative thorium fuel cycle offer increased proliferation resistance compared to conventional uranium cycle.

The modular construction of SMRs is another useful feature. Because the reactor core is often constructed completely inside a central manufacturing facility, fewer people have access to the fuel before and after irradiation.

Reactor designs

There are numerous new reactor designs being generated all over the world. A small selection of the current SMR designs is listed below.CAREM: Argentina

CAREM reactor logo

The fuel is uranium oxide with a 235U enrichment of 3.4%. The primary coolant system uses natural circulation, so there are no pumps required, which provides inherent safety against core meltdown, even in accident situations. The integral design also minimizes the risk of loss-of-coolant accidents (LOCA). Annual refueling is required.[22] Currently, the first reactor of the type is being built near the city of Zárate, in the northern part of Buenos Aires provice.

Encapsulated Nuclear Heat Source (ENHS): United States

ENHS is a liquid metal reactor (LMR) that uses lead (Pb) or lead-bismuth (Pb-Bi) coolant. Pb has a higher boiling point than the other commonly used coolant metal, sodium, and is chemically inert with air and water. The difficulty is finding structural materials that will be compatible with the Pb or Pb-Bi coolant, especially at high temperatures. The ENHS uses natural circulation for the coolant and the turbine steam, eliminating the need for pumps. It is also designed with autonomous control, with a load-following power generation design, and a thermal-to-electrical efficiency of more than 42%. The fuel is either U-Zr or U-Pu-Zr, and can keep the reactor at full power for 15 years before needing to be refueled, with either 239Pu at 11% or 235U at 13%It requires on-site storage, at least until it cools enough that the coolant solidifies, making it very resistant to proliferation. However, the reactor vessel weighs 300 tons with the coolant inside, and that can pose some transportation difficulties.[23]

Flibe Energy: United States

Flibe Energy is a US-based company established to design, construct and operate small modular reactors based on liquid fluoride thorium reactor (LFTR) technology (a type of molten salt reactor). The name "Flibe" comes from FLiBe, a Fluoride salt of Lithium and Beryllium, used in LFTRs. Initially 20-50 MW (electric) version will be developed, to be followed by 100 MWe "utility-class reactors" at a later time.[24] Assembly line construction is planned, producing "mobile units that can be dispersed throughout the country where they need to go to generate the power." Initially the company is focusing on producing SMRs to power remote military bases.[25]Hyperion Power Module (HPM): United States

A commercial version of a Los Alamos National Laboratory project, the HPM is a LMR that uses a Pb-Bi coolant. It has an output of 25 MWe, and less than 20% 235U enrichment. The reactor is a sealed vessel, which is brought to the site intact and removed intact for refueling at the factory, reducing proliferation dangers. Each module weighs less than 50 tons. It has both active and passive safety features.[26][27]International Reactor Innovative & Secure (IRIS): United States

Main article: International Reactor Innovative and Secure

Developed by an international consortium led by Westinghouse and the nuclear energy research initiative (NERI), IRIS-50

is a modular PWR with a generation capacity of 50MWe. It uses natural

circulation for the coolant. The fuel is a uranium oxide with 5%

enrichment of 235U

that can run for five years between refueling. Higher enrichment might

lengthen the refueling period, but could pose some licensing problems.

Iris is an integral reactor, with a high-pressure containment design.[26][28]Modified KLT-40: Russia

Based on the design of nuclear power supplies for Russian icebreakers, the modified KLT-40 uses a proven, commercially available PWR system. It is intended to be portable. The coolant system relies on forced circulation of pressurized water during regular operation, although natural convection is usable in emergencies. The fuel may be enriched to above 20%, the limit for low-enriched uranium, which may pose non-proliferation problems. The reactor has an active (requires action) safety system with an emergency feedwater system. Refueling is required every two to three years.[29]mPower: United States

The mPower from Babcock & Wilcox (B&W) is an integrated PWR SMR. The nuclear steam supply systems (NSSS) for the reactor arrive at the site already assembled, and so require very little construction. Each reactor module would produce around 180MWe, and could be linked together to form the equivalent of one large nuclear power plant. B&W has submitted a letter of intent for design approval to the NRC.[30] Babcock & Wilcox announced on February 20, 2013 that they had contracted with the Tennessee Valley Authority to apply for permits to build an mPower small modular reactor at TVA's Clinch River site in Oak Ridge, Tennessee.[31][32]NuScale: United States

Originally a Department of Energy and Oregon State University project, the NuScale module reactors have been taken over by NuScale Power, Inc. The NuScale is a light water reactor (LWR), with 235U fuel enrichment of less than 4.95%. It has a 2-year refueling period. The modules, however, are exceptionally heavy, each weighing approximately 500 tons. Each module has an electrical output of 45 MW, and a single NuScale power plant can be scaled from one to 12 modules. The company hopes to have a plant up and running by 2018, after they have received a license from the Nuclear Regulatory Commission.[26][33]Pebble Bed Modular Reactor (PBMR): South Africa

The PBMR is a modernized version of a design first proposed in the 1950s and deployed in the 1960s in Germany. It uses spherical fuel elements coated with graphite and silicon carbide filled with up to 10,000 TRISO particles, which contain uranium dioxide (UO2) and appropriate passivation and safety layers. The pebbles are then placed into a reactor core, comprising around 450,000 "pebbles". The core's output is 165 MWe. It runs at very high temperatures (900°C) and uses helium, a noble gas as the primary coolant; helium is used as it does not interact with structural or nuclear materials. Heat can be transferred to steam generators or gas turbines, which can either use either Rankine (steam) or Brayton (gas turbine) cycles.[26][34] South Africa terminated funding for the development of the PBMR in 2010; most scientists working on the project have moved abroad to nations such as the United States, Australia, and Canada.[35]

Purdue Novel Modular Reactor (PNMR): United States

Based on the boiling water reactor (BWR) designs by General Electric (GE), the PNMR is a small, 200 MWe or 50 MWe variation from Purdue University. The coolant steam drives the turbines directly, eliminating the need for a steam generator. It uses natural circulation, so there are no coolant pumps. The reactor has both negative void and negative temperature coefficients . It uses a uranium oxide fuel with 235U enrichment of 5%, which doesn’t need to be refueled for 10 years. The safety systems include gravity-driven water injection, in case of reactor core depressurization. The PNMR would require temporary on-site storage of spent fuel, and even with the modular design would need significant assembly.[36][37]Remote Site-Modular Helium Reactor (RS-MHR): United States

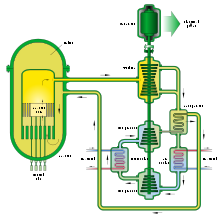

Basic schematic of a Gas-Cooled Reactor.

Super Safe, Small & Simple (4S): Japan

Toshiba 4S reactor design

Main article: Toshiba 4S

Designed by the Central Research Institute of Electric Power Industry (CRIEPI), the 4S is an extremely modular design, fabricated in a factory and requiring very little construction on-site. It is a sodium

(Na) cooled reactor, using a U-Zr or U-Pu-Zr fuel. The design relies on

a moveable neutron reflector to maintain a steady state power level for

anywhere from 10 to 30 years. The liquid metal coolant allows the use

of electro-magnetic (EM) pumps, with natural circulation used in

emergencies.[26][39]Traveling Wave Reactor (TWR): United States

The TWR from Intellectual Ventures' TerraPower team is another innovative reactor design. It is based on the idea of a fission chain reaction moving through a core in a “wave.” The idea is that the slow breeding and burning of fuel would move through the core for 50 to 100 years without needing to be stopped, so long as plenty of fertile 238U is supplied. The only enriched 235U required would be a thin layer to start the chain reaction. So far, the reactor only exists in theory, the only testing done with computer simulations. A large reactor concept has been designed, but the small modular design is still being conceptualized.[40]Westinghouse SMR

The Westinghouse SMR design is a scaled down version of the AP1000 reactor, designed to generate 225 MWe.After losing a second time in December 2013 for funding through the U.S. Department of Energy's SMR commercialization program, and citing "no customers" for SMR technology, Westinghouse announced in January 2014 that it is backing off from further development of the company's SMR. Westinghouse staff devoted to SMR development was "reprioritized" to the company's AP1000. The company is looking to triple its decommissioning business dismantling nuclear plants -- "We see this as a $1 billion-per-year business for us," said Westinghouse CEO and President Danny Roderick.[41]

Licensing Concerns

The NRC’s licensing process up to this point has focused mainly on large commercial reactors. The design and safety specifications, staffing requirements and licensing fees have all been geared toward reactors with an electrical output of more than 700MWe.[42]Licensing for SMRs has been an ongoing discussion. There was a workshop in October 2009 about licensing difficulties and another in June 2010, with a congressional hearing in May 2010. With growing worries about climate change and greenhouse gas emissions, added to problems with hydrocarbon supplies from foreign countries and accidents like the BP oil rig explosion in the Gulf of Mexico, many government agencies are working to push the development of different licensing for SMRs.[43]

No comments:

Post a Comment