From Wikipedia, the free encyclopedia

| F135 | |

|---|---|

|

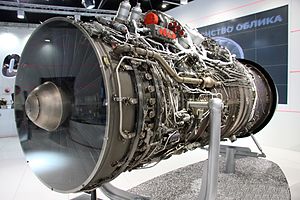

|

| An F135-PW-100 powerplant on display at Royal Australian Air Force Centenary of Military Aviation 2014 | |

| Type | Turbofan |

| Manufacturer | Pratt & Whitney |

| Major applications | Lockheed Martin F-35 Lightning II |

| Developed from | Pratt & Whitney F119 |

Contents

Development

The origins of the F135 lie with the Lockheed Corporation Skunk Works's efforts to develop a stealthy STOVL strike fighter for the U.S. Marine Corps under a 1986 DARPA program. Lockheed employee Paul Bevilaqua developed and patented[2] a concept aircraft and propulsion system, and then turned to Pratt & Whitney (P&W) to build a demonstrator engine.[3] The demonstrator used the first stage fan from a F119 engine for the lift fan, the engine fan and core from the F100-220 for the core, and the larger low pressure turbine from the F100-229 for the low pressure turbine of the demonstrator engine. The larger turbine was used to provide the additional power required to operate the lift fan. Finally, a variable thrust deflecting nozzle was added to complete the "F100-229-Plus" demonstrator engine. This engine proved the lift-fan concept and led to the development of the current F135 engine.[4]P&W developed the F135 from their F119 turbofan, which powers the F-22 Raptor, as the "F119-JSF". The F135 integrates the F119 core with new components optimized for the JSF.[5] The F135 is assembled at a plant in Middletown, Connecticut. Some parts of the engine are made in Longueuil, Quebec, Canada,[6] and in Poland.[7]

The F135-PW-600 engine with lift fan, roll posts, and rear vectoring nozzle, as designed for the F-35B V/STOL variant, at the Paris Air Show, 2007

The F135 team is made up of Pratt & Whitney, Rolls-Royce and Hamilton Sundstrand. Pratt & Whitney is the prime contractor for the main engine, and systems integration. Rolls-Royce is responsible for the vertical lift system for the STOVL aircraft. Hamilton Sundstrand is responsible for the electronic engine control system, actuation system, PMAG, gearbox, and health monitoring systems. Woodward, Inc. is responsible for the fuel system.

As of 2009, P&W was developing a more durable version of the F135 engine to increase the service life of key parts. These parts are primarily in the hot sections of the engine (combustor and high pressure turbine blades specifically) where current versions of the engine are running hotter than expected, reducing life expectancy. The test engine is designated XTE68/LF1, and testing is expected to begin in 2010.[9] This redesign has caused “substantial cost growth.”[10]

P&W expects to deliver the F135 below the cost of the F119, even though it is a more powerful engine.[11]

In February 2013 a cracked turbine blade was found during a scheduled inspection. The crack was caused by operating for longer periods than typical at high turbine temperatures.[12]

The 100th engine was delivered in 2013.[13] LRIP-6 was agreed in 2013 for $1.1 billion for 38 engines of various types, continuing the unit cost decreases.[14]

In 2013, a former P&W employee was caught attempting to ship "numerous boxes" of sensitive information about the F135 to Iran.[15]

In December 2013 the hollow first stage fan blisk failed at 77% of its expected life during a ground test. It will be replaced by a solid part adding 6 lb in weight.[16]

F-35 program office executive officer Air Force Lt. Gen. Christopher C. Bogdan has called out Pratt for falling short on manufacturing quality of the engines and slow deliveries.[17] His deputy director Rear Admiral Randy Mahr said that Pratt stopped their cost cutting efforts after "they got the monopoly".[18] In 2013 the price of the F135 increased by $4.3 billion.[19]

In July 2014 there was an uncontained failure of a fan rotor while the aircraft was preparing for take-off. The parts passed through a fuel tank and caused a fire, grounding the F-35 fleet.[20] The failure was caused by excessive rubbing at the seal between the fan blisk and the fan stator during high-g maneuvering three weeks before the failure. The engine "flex" generated a temperature of 1,900 degrees F in materials designed to fail at 1,000 degrees F. Microcracks appeared in third-stage fan blades, according to program manager Christopher Bogdan, causing blades to separate from the disk; the failed blades punctured the fuel cell and hot air mixing with jet fuel caused the fire.[21][22][23] As a short term fix, each aircraft is flown on a specific flight profile to allow the rotor seal to wear a mating groove in the stator to prevent excessive rubbing.[24]

In May 2014, Pratt & Whitney discovered conflicting documentation about the origin of titanium material used in some of its engines, including the F135. The company assessed that the uncertainty did not pose a risk to safety of flight but suspended engine deliveries as a result in May 2014. Bogdan supported Pratt's actions and said the problem was now with A&P Alloys, the supplier. The US Defense Contract Management Agency wrote in June 2014 that Pratt & Whitney’s "continued poor management of suppliers is a primary driver for the increased potential problem notifications." A&P Alloys stated that it has not been given access to the parts to do its own testing but stood behind its product. Tracy Miner, an attorney with Boston-based Demeo LLP representing A&P Alloys said, "it is blatantly unfair to destroy A&P’s business without allowing A&P access to the materials in question".[25][26][27]

Design

Thrust vectoring nozzle of the F135-PW-600 STOVL variant

There are 3 F-135 variants with the -400 being similar to the -100, the major difference being the use of salt-corrosion resistant materials.[29] The -600 is described below with an explanation of the engine configuration changes that take place for hovering. The engine and Rolls-Royce LiftSystem make up the Integrated Lift Fan Propulsion System(ILFPS).[30]

The lift for the STOVL version in the hover is obtained from a 2-stage lift fan (about 46%[31]) in front of the engine, a vectoring exhaust nozzle (about 46%[31]) and a nozzle in each wing using fan air from the bypass duct(about 8%[31]). These relative contributions to the total lift are based on thrust values of 18,680lb, 18,680lb and 3,290lb respectively.[31] Another source gives thrust values of 20,000lb, 18,000lb and 3,900lb respectively.[32]

In this configuration most of the bypass flow is ducted to the wing nozzles, known as roll posts. Some is used for cooling the rear exhaust nozzle, known as the 3 bearing swivel duct nozzle(3BSD).[33] At the same time an auxiliary inlet is opened on top of the aircraft to provide additional air to the engine with low distortion during the hover.[28]

The lift fan is driven from the LP turbine through a shaft extension on the front of the LP rotor and a clutch. The engine is operating as a separate flow turbofan with a higher bypass ratio.[34] The power to drive the fan (about 30,000 SHP[34]) is obtained from the LP turbine by increasing the hot nozzle area.[34]

A higher bypass ratio increases the thrust for the same engine power as a fundamental consequence of transferring power from a small diameter propelling jet to a larger diameter one.[35] The thrust augmentation for the F-135 in the hover using its higher bypass ratio is about 50%[31] with no increase in fuel flow. Thrust augmentation in horizontal flight using the afterburner is about 52%[31] but with a large increase in fuel flow.

The transfer of approximately 1/3[34]of the power available for hot nozzle thrust to the lift fan reduces the temperature and velocity of the rear lift jet impinging on the ground.[34]

Improving engine reliability and ease of maintenance is a major objective for the F135. The engine has fewer parts than similar engines which should improve reliability. All line-replaceable components (LRCs) can be removed and replaced with a set of six common hand tools.[36] The F135's health management system is designed to provide real time data to maintainers on the ground, allowing them to troubleshoot problems and prepare replacement parts before the aircraft returns to base. According to Pratt & Whitney, this data may help drastically reduce troubleshooting and replacement time, as much as 94% over legacy engines.[37]

The F-35 can achieve a limited supercruise of Mach 1.2 for 150 miles.[38]

Because the F135 is designed for a fifth generation jet fighter, it is the second afterburning jet engine to use special "low-observable coatings".[39]

Variants

- F135-PW-100 : Used in the F-35A Conventional Take-Off and Landing variant

- F135-PW-400 : Used in the F-35C carrier variant

- F135-PW-600 : Used in the F-35B Short Take-Off Vertical Landing variant

Specifications (F135-PW-100)

Data from F135engine.com[40]

General characteristics

- Type: Afterburning Turbofan

- Length: 220 in (559 cm)

- Diameter: 46 in (117 cm)[41]

- Dry weight: 3,750 lbs (1,701 kg)

Components

- Compressor: 3 stage fan,6 stage high-pressure compressor

- Combustors: annular combustor

- Turbine: Single stage high pressure turbine, two stage low pressure turbine

Performance

- Maximum thrust: 43,000 lbf (191.35 kN) max, 28,000 lbf (124.6 kN) intermediate

- Specific fuel consumption: 0.886 lb/(hr·lbf) or 25,0 g/kN·s (w/o afterburner)

- Thrust-to-weight ratio: 7.47:1 (dry), 11.467:1 (wet/afterburning)

Rolls-Royce LiftSystem

From Wikipedia, the free encyclopedia

| LiftSystem | |

|---|---|

|

|

| The Rolls-Royce LiftSystem coupled to an F135 turbofan at the Paris Air Show in 2007 | |

| Type | STOVL Lift system |

| Manufacturer | Rolls-Royce plc |

| Major applications | F-35 Lightning II |

Contents

Requirement

The F-35B STOVL variant of the Joint Strike Fighter (JSF) aircraft is intended to replace the vertical flight Harrier, which was the world's first operational short-takeoff / vertical-landing fighter. A requirement of the JSF is that it can attain supersonic flight, and a suitable vertical lift system that would not compromise this capability was needed for the STOVL variant. The solution came in the form of the Rolls-Royce LiftSystem, developed through a $1.3 billion System Development and Demonstration (SDD) contract from Pratt & Whitney.[2] This requirement was met on 20 July 2001.[3][4]Design and development

Instead of using lift engines or rotating nozzles on the engine fan like the Harrier, the "LiftSystem" has a shaft-driven LiftFan, designed by Lockheed Martin and developed by Rolls-Royce,[2] and a thrust vectoring nozzle for the engine exhaust that provides lift and can also withstand the use of afterburners in conventional flight to achieve supersonic speeds.[3] The system has more similarities to the Russian Yakovlev Yak-141 and German EWR VJ 101D/E than the preceding generation of STOVL designs to which the Harrier belongs. [5]The team responsible for developing the propulsion system includes Lockheed Martin, Northrop Grumman, BAE Systems, Pratt & Whitney and Rolls-Royce, under the leadership of the United States Department of Defense Joint Strike Fighter Program Office. Paul Bevilaqua,[6] Chief Engineer of Lockheed Martin Advanced Development Projects (Skunk Works), invented the lift fan propulsion system.[7] The concept of a shaft-driven lift-fan dates back to the mid-1950s.[8] The lift fan was demonstrated by the Allison Engine Company in 1995-97.[9]

The U.S. Department of Defense (DOD) awarded General Electric and Rolls-Royce a $2.1 billion contract to jointly develop the F136 engine as an alternative to the F-135. The LiftSystem was designed to be used with either engine.[2] Following termination of government funding GE and Rolls-Royce terminated further development of the engine in 2011.[10]

Rolls-Royce is managing the overall development and integration programme from its site in Bristol, UK, which is also responsible for the LiftFan turbomachinery, 3BSM and Roll Post designs. The team in Indianapolis, US, will provide the system’s gearbox, clutch, driveshaft and nozzle and will conduct the build and verification testing of the LiftFan.

Operation

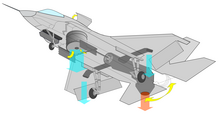

Diagram of LiftSystem components and airflow

Diagram of turbojet energy for LiftSystem prototype

Diagram of powered lift aircraft

- LiftFan

- Engine to fan driveshaft [11]

- Three-bearing swivel module (3BSM)

- Roll posts (two)

In "lift" mode for assisted vertical maneuvers, 29,000 hp[13][14][15] is diverted forward through a driveshaft from the engine's low-pressure (LP) turbine via a clutch[16] and bevel-gearbox to a vertically mounted, contra-rotating lift fan located forward of the main engine. The fan efflux (low-velocity unheated air) discharges through a thrust vectoring nozzle on the underside of the aircraft, thus balancing the aft lift generated by the 3BSM. For lateral stability and roll control, bypass air from the engine goes out through a roll-post nozzle in each wing.[17] For pitch control, the areas of exhaust nozzle and LiftFan inlet are varied conversely to change the balance between them while maintaining their sum, and with constant turbine speed. Yaw control is achieved by yawing the 3BSM.[15] Forward, and even backward, motion is controlled by tilting the 3BSM and LiftFan outlet.[4]

The following indicates the component thrust values of the system in lift mode:[2]

| 3BSM (dry thrust) | LiftFan | Roll posts (combined) | Total |

|---|---|---|---|

| 18,000 lbf (80 kN) | 20,000 lbf (89 kN) | 3,900 lbf (17 kN) | 41,900 lbf (186 kN) |

In comparison, the maximum thrust of the Rolls-Royce Pegasus 11-61/F402-RR-408, the most powerful version which is used in the AV-8B, is 23,800 pounds-force (106 kN).[18] The weight of the AV-8B is about 46% of the weight of the F-35B.

Like lift engines, the added LiftSystem components are dead weight during flight, but the advantage of employing the LiftSystem is that its greater lift thrust increases takeoff payload by an even larger amount.[citation needed] Also, the fan's cool efflux reduces the harmful effects of hot, high-velocity air which can harm runway pavement or an aircraft carrier deck.[citation needed]

Engineering challenges

While developing the LiftSystem many engineering difficulties had to be overcome, and new technologies exploited.[19]The LiftFan utilises hollow-bladed titanium blisks (a bladed disk or "blisk" achieved by super-plastic forming of the blades and linear friction welding to the blisk hub).[20] Organic matrix composites are used for the interstage vanes. The LiftFan must safely function[21] at flight speeds up to 250 knots (130 m/s) This condition appears as a crosswind to the horizontal intake and occurs when the aircraft transitions between forward flight and hover.[22]

The clutch mechanism uses dry plate carbon–carbon technology originally derived from aircraft brakes. Friction is only used to engage the lift fan at low engine speeds. A mechanical lock-up is engaged before increasing to full power.[23]

The gearbox has to be able to operate with interruptions to its oil supply of up to a minute while transferring full power through 90 degrees to the LiftFan.[citation needed]

The Three-Bearing Swivel Module has to both support the final hot thrust vectoring nozzle and transmit its thrust loads back to the engine mounts. The "fueldraulic" actuators for the 3BSM use fuel pressurised to 3,500 lbf/in2, rather than hydraulic fluid, to reduce weight and complexity. One actuator travels with the swivel nozzle, moving through 95 degrees while subject to intense heat and vibration.[citation needed]

Testing

During concept definition of the Joint Strike Fighter, two Lockheed airframes were flight-tested: the Lockheed X-35A (which was later converted into the X-35B), and the larger-winged X-35C,[24] with the STOVL variant incorporating the Rolls-Royce LiftFan module.LiftSystem flight testing commenced in June 2001, and on 20 July that year the X-35B became the first aircraft in history to perform a short takeoff, a level supersonic dash and vertical landing in a single flight. By the time testing had been completed in August, the aircraft had achieved 17 vertical takeoffs, 14 short takeoffs, 27 vertical landings and five supersonic flights.[3] During the final qualifying Joint Strike Fighter flight trials, the X-35B took off in less than 500 feet (150 m), transitioned to supersonic flight, then landed vertically.[25]

Ground tests of the F136/LiftSystem combination were carried out at the General Electric facility in Peebles, Ohio in July 2008. On 18 March 2010, a STOVL equipped F-35B performed a vertical hover and landing demonstration at Patuxent River Naval Air Station in Lexington Park, MD.[26]

Collier Trophy award

In 2001, the LiftSystem propulsion system was awarded the prestigious Collier Trophy,[27] in recognition of "the greatest achievement in aeronautics or astronautics in America", specifically for "improving the performance, efficiency and safety of air or space vehicles, the value of which has been thoroughly demonstrated by actual use during the preceding year."[3]Specifications (LiftSystem)

- Main engine

- Pratt & Whitney F135

- 17,600 pounds-force (78 kN) dry thrust

- LiftFan

- Two-stage contra-rotating hollow titanium blisk fan of 50 inches (1.3 m) diameter. Uppermost fan fitted with variable inlet guide vanes. Capable of generating more than 20,000 pounds-force (89 kN) cold thrust[20]

- Three-bearing swivel module

- Able to rotate through 95 degrees in 2.5 seconds and vector 18,000 pounds-force (80 kN) dry thrust in lift mode, with reheat capability in normal horizontal attitude

- Roll posts

- Two: hydraulically actuated

Pratt & Whitney F119

From Wikipedia, the free encyclopedia

| F119 | |

|---|---|

|

|

| F119 engine on test | |

| Type | Turbofan |

| Manufacturer | Pratt & Whitney |

| Major applications | F-22 Raptor |

| Developed into | Pratt & Whitney F135 |

The engine delivers thrust in the 35,000 lbf (160 kN) class, and is designed for supersonic flight without the use of afterburner (supercruise). Delivering almost 22% more thrust with 40% fewer parts than conventional, fourth-generation military aircraft engine models, the F119 allows sustained supercruise speeds of up to Mach 1.72.[2] The F119's nozzles incorporate thrust vectoring technology. These nozzles direct the engine thrust ±20° in the pitch axis to give the F-22 enhanced maneuverability.

The F119 derivative, the F135, produces 40,000 lbf (180 kN) of thrust[3] for the Lockheed Martin F-35 Lightning II.

Contents

History

In 2013 Pratt assisted the F119 Heavy Maintenance Center (HMC) at Tinker Air Force Base, Oklahoma in the first depot overhaul of a F119 engine.[4]Applications

Specifications (F119)

Fan.

Thrust vectoring nozzle

General characteristics

- Type: twin-spool, augmented turbofan[5]

- Length: 16 ft 11 in (516 cm)[6]

- Diameter: Approx. 46 in (120 cm)

- Dry weight: 3,900 lb (1,800 kg)[7]

Components

- Compressor: Twin spool, counter rotating, axial flow, low aspect ratio[5] 3-stage low-pressure, 6-stage high-pressure compressor

- Combustors: Annular combustor

- Turbine: Twin spool, axial flow, counter-rotating 1-stage high-pressure, 1-stage low-pressure turbines

- Nozzle: 2-dimensional vectoring convergent-divergent

Performance

- Maximum thrust: >35,000 lbf (156 kN) (with afterburner)[8]

- Thrust-to-weight ratio: > 9

Saturn AL-41

From Wikipedia, the free encyclopedia

| AL-41F | |

|---|---|

|

|

| AL-41F1S engine | |

| Type | Turbofan |

| National origin | Russia |

| Manufacturer | NPO Saturn |

Contents

Design and development

The AL-41F program was launched in 1982, and the first prototype engine flew in a MiG-25 Foxbat testbed. Originally developed for the Mikoyan Project 1.44,[1][2] 28 engines were built, however the engine did not advance beyond prototype stage and when the MiG 1.44 was cancelled, it was also cancelled.The AL-41 designation was reused for heavily upgraded variants of the AL-31 used to power the Su-35S (Izdeliye 117S / AL-41F1A) and initial production PAK FA (Izdeliye 117 / AL-41F1) aircraft. Some of the technologies of the original AL-41F were applied in the 117S and 117 engines.

Variants

A heavily-upgraded version of the AL-31F is being developed for the Su-35BM and PAK FA. This engine has been named the AL-41F1S and AL-41F1. It is important to note that the AL-41F1S is not considered a part of the same AL-41 line as was planned for the Mikoyan Project 1.44 because it uses the core of the AL-31F, whereas the AL-41F utilizes an entirely new core. The designation appears to be present because the engine approaches the projected specifications of the new AL-41F class. It is also notable that the engine is capable of mounting 3D thrust vectoring nozzles for extra manoeuvrability.Specifications

General characteristics

- Type: Turbofan

- Length: 4990 mm

- Diameter: 1280 mm

- Dry weight:

Components

- Compressor: axial

Performance

- Maximum thrust: 18,000 kgf (180,000 N; 40,000 lbf)

- Thrust-to-weight ratio: 11:1

Saturn AL-31

From Wikipedia, the free encyclopedia

| AL-31 | |

|---|---|

|

|

| Saturn AL-31 FN turbofan engine | |

| Type | Turbofan |

| National origin | USSR |

| Manufacturer | NPO Saturn |

| Major applications | Sukhoi Su-30MKI Sukhoi Su-27 Chengdu J-10 |

The AL-31FP and AL-37FU variants have thrust vectoring. The former is used in the Su-30MKI export version of the Su-30 for India & Sukhoi Su-30MKM for Malaysia . The AL-37FU can deflect its nozzle to a maximum of ±15° at a rate of 30°/sec. The vectoring nozzle is utilized primarily in the pitch plane. The AL-31FP is built in India by HAL at the Koraput facility under a deep technology transfer agreement.

It has a reputation for having a tremendous tolerance to severely disturbed air flow. In the twin-engined Su-27, the engines are interchangeable between left and right. The Mean Time Between Overhaul (MTBO) for the AL-31F is given at 1000 hours with a full-life span of 3000 hours. Some reports suggested that Russia was offering AL-31F to Iran to re-engine its F-14 Tomcat air fleet in the late 1990s.

According to Saturn`s Victor Mihailovic Chepkin, chief designer of the 117 and 117S engines, the Chinese WS-10 was developed with the aid of the AL-31`s maintenance technical documentation.[10] China can domestically produce most AL-31 parts for its own jet engine programs, but must import turbine blades from Russia.[11]

117S

Intended to power the Su-35BM, the izdeliye 117S (AL-41F1S) is an upgrade of the AL-31F that uses technology from the AL-41F. The engine produces 142 kN (32,000 lb) of thrust in afterburner and 86.3 kN (19,400 lb) dry.[12] It features a fan 3% larger in diameter (932 millimetres (36.7 in) versus 905 millimetres (35.6 in)), advanced high- and low-pressure turbines, an all-new digital control system, and provisions for thrust-vectoring nozzles similar to the AL-31FP. This engine will have an assigned life of 4,000 hours and an MTBO of 1,000 hours.[13] The first flight of this engine was completed in an Su-35BM on 20 February 2008.[14] On 9 August 2010, Ufa-based company UMPO started supplying 117S engines (AL-41F1S) intended for Su-35S fighters.[15]117

Related to the 117S is the izdeliye 117 (AL-41F1), a highly improved AL-31F derivative designed for the Sukhoi T-50 fighter. The engine features an increased diameter fan, new high and low pressure turbines, and a digital control system (FADEC). According to Sukhoi director Mikhail Pogosyan, the 117 is a new fifth generation engine built specifically for the PAK FA. Though the specifics of the 117 engine remain classified, the engine's thrust was increased by 24.5 kN (5,500 lbs) over the AL-31 while the engine weight was reduced by 150 kg (330 lb). The new engine produces 147 kN (33,067 lbf) of thrust in afterburner and has a dry weight of 1,420 kg (3,130 lb) and thrust-to-weight ratio of 10.5:1.[16] Mikhail Pogosyan further mentioned that the 117 engine meets the Russian Air Force requirements and will be installed in production PAK-FA fighter which will be supplied to the Russian Air Force and prospective foreign clients.[17]The 117 is an interim engine meant for prototype and initial production batches of the T-50. The definitive second stage for the aircraft is designated izdeliye 30 and will eventually replace the 117 after 2020. The new engine has increased thrust and fuel efficiency as well as improved reliability and lower costs. Bench testing of the new engine will start in 2014 according to the general designer-director of the NPO Saturn Eugeny Marchuk.[18]

Specifications (AL-31F)

Data from [19]

General characteristics

- Type: Two-shaft afterburning turbofan

- Length: 4,990 millimetres (196 in)

- Diameter: 905 millimetres (35.6 in) inlet; 1,280 millimetres (50 in) maximum external

- Dry weight: 1,570 kilograms (3,460 lb)[20]

Components

- Compressor: 4 fan and 9 compressor stages

- Combustors: annular

- Turbine: 2 single-staged turbines

Performance

- Maximum thrust:

- 74.5 kilonewtons (16,700 lbf) dry thrust

- 122.58 kilonewtons (27,560 lbf) with afterburner

- Overall pressure ratio: 23

- Bypass ratio: 0.59:1

- Turbine inlet temperature: 1685 K (1,412 °C (2,574 °F))

- Fuel consumption: 2.0 Kg/daN·h

- Specific fuel consumption:

Full afterburner: 1.92 lb/(lbf·h)

- Thrust-to-weight ratio: 4.77:1 (dry), 7.87:1 (afterburning)

Xian WS-15

From Wikipedia, the free encyclopedia

| WS-15 | |

|---|---|

| Type | Turbofan |

| National origin | People's Republic of China |

| Manufacturer | Xi'an Aero-Engine Company |

| First run | 2006[1] |

| Major applications | Chengdu J-20 |

Contents

Design and development

The People's Republic of China began development of the WS-15 in the 1990s, designed to produce a maximum 180 kN[2] thrust with afterburner, similar to the Pratt & Whitney F119 and is expected to power future 5th-Generation fighters.[2][3] The 'Core' of the WS-15 was displayed for the first time in 2010.[4][5] A high thrust turbofan for transport aircraft based on the WS-15 Core[6] has been developed. This turbofan designated SF-A[6] and is developed for the Y-20[6] military transport aircraft and the civilian C919[6] airliner.The design and development of the WS-15 engine used many valuable experiences learned from the previous WS-10 turbofan engine program started in the early 1980s; this will significantly help and reduce the developmental time and risks of the WS-15 program.

Applications

Specifications (WS-15)

Source[7]General characteristics

- Type: Afterburning turbofan

- Length: 5.05m

- Diameter: 1.02m

- Dry weight: 1,862kg

Components

- Compressor: axial

Performance

- Maximum thrust:

- Prototype: 16,500 kilograms (36,400 lb) with afterburner

- Goal: 18,350 kilograms (40,450 lb) / (180 kilonewtons (40,000 lbf)) with afterburner[2]

- Turbine inlet temperature: 1447K

- Thrust-to-weight ratio:

- Prototype: 9

- Goal: 10

General Electric YF120

From Wikipedia, the free encyclopedia

The General Electric YF120 was a variable cycle turbofan engine designed by GE Aircraft Engines in the late 1980s/early 1990s for the United States Air Force's Advanced Tactical Fighter (ATF) project (which resulted in the F-22 Raptor). GE lost the engine competition for this aircraft to Pratt & Whitney F119.YF120 Type Variable Cycle Turbofan National origin United States Manufacturer General Electric First run 1980s Major applications Lockheed YF-22

Northrop YF-23Developed into General Electric/Rolls-Royce F136

Contents

Development and Design

General Electric began developing the YF120 for the ATF competition in the early 1980s. Unlike competitor Pratt & Whitney, GE elected against developing a conventional low bypass turbofan and instead chose to design a variable cycle engine. This decision was made as a result of the challenging ATF requirement of supercruise. This meant the engine had to produce a large amount of dry thrust (without afterburner) and therefore have high off-design efficiency ("design" being standard cruise conditions).[1]

The core technology used in the YF120 was developed during two industry-government programs, the Advanced Technology Engine Gas Generator (ATEGG) and Joint Technology Demonstration Engine (JTDE) programs.[2]

Variable Cycle

The YF120's variable cycle system worked by varying the bypass ratio of engine for different flight regimes, allowing the engine act like either a low bypass turbofan or nearly a turbojet.[1] As a low bypass turbofan (like competitor F119), the engine performed similar to comparable engines. When needed, however, the engine could direct more airflow through the hot core of the engine (like a turbojet), increasing the specific thrust of the engine. This made the engine more efficient at high altitude, high thrust levels than a traditional low bypass turbofan.[3]

An expected disadvantage of this variable cycle system would be increased complexity and weight. GE claims to have combated this by using simple pressure driven valves rather than complex mechanically actuated valves to divert airflow. GE stated that this system resulted in the variable cycle system adding only 10 lb to the engine.[1] Additionally a production F120 engine was expected to have 40% fewer parts than the F110 engine.[2]

Thrust Vectoring

The YF120 engine featured a two-dimensional thrust vectoring nozzle. The nozzle allowed for vectoring in the pitch direction. This capability gave the aircraft it was installed in a serious advantage in pitch agility by greatly increasing the amount of nose pitching moment available to the aircraft. The pitching moment is traditionally generated by the horizontal stabilizer (and/or canard, if applicable), but with a thrust vectoring nozzle that moment can be augmented by the thrust of the engine.[citation needed]

While the YF120 engine never went into production, it was installed in the YF-22 used for the high angle of attack demonstration program as part of the ATF competition. During this demonstration, the YF120 powered aircraft flew, trimmed, at 60 degrees angle of attack at 82 knots. At this attitude the aircraft was able to demonstrate controlibility. Later analysis revealed that the aircraft could have maintained controlled, trimmed flight up to 70 degrees angle of attack.[4]

Advanced Development

The YF120 was also proposed as the basis for a more exotic engine, the Turbine-Based Combined Cycle (TBCC) engine that was to be used in demonstrator aircraft like the X-43B and future hypersonic aircraft. Specifically, the YF120 was to be the basis for the Revolutionary Turbine Accelerator (RTA-1). The variable cycle technology used in the YF120 would be extended to not only turn the engine into a turbojet but also into a ramjet. In that mode all airflow would bypass the core and be diverted into the afterburner-like "hyperburner" where it would be combusted like a ramjet. This proposed engine was to accelerate from 0 to Mach 4.1 (at 56,000 ft) in eight minutes.[5][6]

Applications

- Lockheed YF-22

- Northrop YF-23

Specifications (YF120)

Data from[citation needed]

General characteristics

- Type: Twin-Spool, Augmented Turbofan

- Length: 4,242 mm

- Diameter: 1,067 mm

- Dry weight: 1,860 kg

Components

- Compressor: Two stage fan, five stage high pressure compressor (estimated[2])

- Combustors: Annular Combustor

- Turbine: Single stage HPT, Counter-Rotating Single Stage LPT [7]

- Nozzle: Two Dimensional Vectoring Convergent/Divergent

- Fuel type: JP-4 or JP-8

Performance

- Maximum thrust: 35,000 lbf (160 kN) - class

- Power-to-weight ratio:

General Electric/Rolls-Royce F136

From Wikipedia, the free encyclopedia

| F136 | |

|---|---|

|

|

| An F136 | |

| Type | Turbofan |

| National origin | United States / United Kingdom |

| Manufacturer | General Electric Rolls-Royce plc |

| First run | 21 July 2004 |

| Major applications | Lockheed Martin F-35 Lightning II |

| Developed from | General Electric YF120 |

Contents

Development

All early F-35s were to be powered by the Pratt & Whitney F135 but it was planned that engine contracts would be competitively tendered from Lot 6 onward. The engines selected would be either the F135 or an engine produced by the GE/RR Fighter Engine Team and designated the F136. The GE/RR Fighter Engine Team was a co-operation between GE Aviation in Cincinnati, Ohio, United States (60% share) and Rolls-Royce in Bristol, United Kingdom and Indianapolis, Indiana, USA (40% share).On 21 July 2004, the F136 began full engine runs at GE's Evendale, Ohio facility. The engine ran for over an hour during two separate runs. In August 2005, the United States Department of Defense awarded the GE and Rolls-Royce team a $2.4 billion contract to develop its F136 engine. The contract was for the system development and demonstration (SDD) phase of the F136 initiative, scheduled to run until September 2013.

The US Defense budget announced on 6 February 2006 excluded the F136 — leaving Pratt & Whitney, maker of the F135 engine, as the sole provider of engines for the Lockheed Martin F-35 fighters. Congress, however, overturned this request and allocated funds for FY 2007 later in 2006. In November 2006, the General Electric/Rolls-Royce team successfully completed a 3-month preliminary design review by the F-35 Program Office and the prime contractor, Lockheed Martin.[1]

On 13 February 2008, the GE Rolls-Royce Fighter Engine Team successfully completed its Critical Design Review (CDR) for the F136. During CDR, the U.S. Government's Joint Program Office for the F-35 Lightning II validated and approved the design of the engine. Also during the review, every aspect of the engine design was analyzed and evaluated in order to proceed with the building of the first full development engines. The process involved 80 detailed component and module design reviews, involving technical experts from the JPO, General Electric and Rolls-Royce.[2]

On 20 March 2008, the F136 successfully completed a high-altitude afterburner testing program at the US Air Force Arnold Engineering Development Center in Tennessee, including common exhaust hardware for the F-35 Lightning II aircraft. All test objectives were reached as planned using an engine configured with Conventional Takeoff and Landing (CTOL) and Short Takeoff Vertical Landing (STOVL) common exhaust systems. The engine configuration included a production-size fan and functional augmenter allowing several run periods to full afterburner operation.[3] The GE Rolls-Royce Fighter Engine Team successfully completed Short Take Off, Vertical Landing (STOVL) testing on an F136 engine at the GE testing facility at Peebles, Ohio on 16 July 2008.[4]

The first complete new-build F136 engine began testing 30 January 2009, under the System Development and Demonstration (SDD) contract with the US Government Joint Program Office for the F-35 Joint Strike Fighter program. This marked the first complete engine assembled following US Government validation of the F136 design in 2008. The milestone was achieved one month ahead of schedule.[5]

Citing the Weapon Systems Acquisition Reform Act of 2009, the GE Rolls-Royce Fighter Engine Team submitted an unsolicited fixed-price offer for the F136 to the Pentagon on 28 September 2009. The fixed-price approach would cover initial F136 engine production, beginning with the F136 second production lot. According to the GE Rolls-Royce Fighter Engine Team, the proposal would shift significant cost risk from taxpayers to the Fighter Engine Team until head-to-head competition begins between the F136 and the Pratt & Whitney F135 engine in 2013.[6]

From 2006 to 2010 the Defense Department has not requested funding for the alternate F136 engine program, but Congress has maintained program funding.[7][8]

On 19 December 2009, U.S. Congress approved continued funding for the F136 engine program in fiscal year 2010.[9] The U.S. Defense Department did not request FY 2010 funding for the F136 engine program. In a report filed on 18 June 2009, the House Armed Services Committee cited Pratt & Whitney F135 engine program cost overruns of $1.872 billion as cause to continue funding the F136 engine.[10][11]

On 2 November 2009, the F136 team said that they would redesign a small part of the diffuser leading to the combustor after a failure during testing.[12] Testing resumed on January 22, 2010.[13] The GE Rolls-Royce Fighter Engine Team is currently in the fourth year of its System Development and Demonstration (SDD) contract with the US Government Joint Program Office. The Fighter Engine Team has totaled more than 800 hours of testing on pre-SDD and SDD engines. In early 2010, full afterburning thrust was reached in testing of the first production standard engine.[14]

On 24 March 2011, the Department of Defense issued a 90-day temporary stop work order after Congress failed to pass the defense budget. GE declared that it would continue work on the engine program with their own funds in spite of the stop-work order, as allowed in the order and as had been suggested by Schwartz the previous year.[15][16][17] However GE is limited to design work only, as the stop-work prevents their use of the existing hardware.[18]

On 12 April 2011, GE reduced its team on project from 1,000 workers down to 100, who will work on the F136 and engine technologies for "future combat aircraft".[19][20] GE will redeploy the workers to commercial projects, but will not hire the hundreds of new engineers it was expecting.[21] On 25 April 2011, the Department of Defense ended the contract with GE and demanded that the engines built to date be turned over.[22]

On 5 May 2011, GE and RR offered to pay for the development through FY2012 and asked for access to the materials.[23] By switching to self funding the cost would reduce from $480 million a year to only $100 million, 60% to be paid by GE and 40% to be paid by RR.[24] After self-funding the project GE and Rolls-Royce announced on 2 December 2011, that they would not continue development of the F136 engine because it is not in their best interest.[25][26][27]

Design

The F136 produces 18,000 lbf (80.1 kN) of lift thrust in STOVL configuration. Combined with thrust from the LiftFan (20,000 lbf or 89.0 kN) and two roll posts (1,950 lbf or 8.67 kN each), the Rolls-Royce LiftSystem produces a total of 41,900 lbf (186 kN) of thrust.[28] This compares with the maximum thrust of 23,800 lbf (106 kN) for the Harrier's Rolls-Royce Pegasus engine.Applications

Specifications

Data from[citation needed]

General characteristics

- Type: Twin-Spool, Augmented Turbofan

- Length: 221 in (560 cm)

- Diameter: 48 in (120 cm)

- Dry weight:

Components

- Compressor: Twin Spool/Counter Rotating/Axial Flow/Low Aspect Ratio

- Combustors: Annular Combustor

- Turbine: Axial Flow/Counter-Rotating

Performance

- Maximum thrust: 40,000 lbf; 25,000 lbf without afterburner[citation needed]

- Power-to-weight ratio:

How Things Work: Supersonic Inlets

How Things Work: Supersonic Inlets

By

Air & Space Magazine

We were in a turn and climbing when one

of the inlets showed signs of instability. Shortly thereafter—KER

BLAM!—the aircraft slammed my head against the side of the cockpit and

then momentarily became unstable as it yawed, pitched, and vibrated.”

This is an account of a supersonic engine inlet failure, or

“unstart,” recalled by retired reconnaissance systems officer Roger

Jacks in SR-71 Revealed, a book by retired Lockheed SR-71 pilot Richard

H. Graham. It shows what can happen when a supersonic inlet stops

delivering the uniform stream of air upon which efficient jet engine

operation depends.

When a jet airplane is flying faster than Mach 1—beyond the speed of sound—the air entering the engines is moving supersonically as well. But no turbojet engine compressor—the rotating disks and blades at the face of the engine that compress the air before it is mixed with fuel—is capable of handling supersonic air flow. The job of an engine inlet is to slow incoming air to subsonic speeds before it passes through the engine.

The inlet’s job is complicated by the fact that air moving

supersonically behaves differently from subsonic air. An aircraft flying

subsonically pushes through the air ahead of it, with each molecule of

air having plenty of time to pass over its wings and fuselage. But as an

airplane approaches Mach 1, it compresses the air ahead of it into

shock waves—bands of air radiating from the airplane that are much

hotter and denser than the ambient air.

Turbojet engines cannot digest the shock waves generated by their inlets, so a crucial role of the inlet is to keep the inevitable shock waves positioned so that they do no harm. The SR-71 Blackbird, a now-retired twin-engine reconnaissance aircraft, has an inlet design based on a cone-shaped body, or spike, that generates an oblique-angled, cone-shaped shock wave at the inlet’s entrance and a normal shock wave—one rising at a right angle from the direction of air flow—just aft of the internal inlet throat.

As the SR-71 increases its speed, the inlet varies its exterior and interior geometry to keep the cone-shaped shock wave and the normal shock wave optimally positioned. Inlet geometry is altered when the spike retracts toward the engine, approximately 1.6 inches per 0.1 Mach. At Mach 3.2, with the spike fully aft, the air-stream-capture area has increased by 112 percent and the throat area has shrunk by 54 percent.

The cone shape of the spike also incrementally reduces the speed of the incoming supersonic air without producing a drastic loss of pressure. The farther back over the cone the air moves, the more speed it bleeds off. As the slowed, but still supersonic, air continues to move farther into the inlet, the normal shock wave springs up between the inlet throat and the engine compressor—exactly where it is supposed to be. Once there, the normal shock wave slows the air passing through it to subsonic speeds, preparing it to enter the compressor.

It is a constant balancing act to keep the normal shock wave in the right position. The inlet has an internal pressure sensor, and when it detects that the pressure has grown too great, it triggers the forward bypass doors to open, expelling excess air. The inlet also has a set of aft bypass doors, controlled by the pilot. The forward and aft bypass doors work in opposition to each other: Opening the aft doors causes the forward doors to close, and when the pilot closes the aft doors, the forward doors open in turn.

During some Blackbird flights, however, the harmonious working of the spike and the forward and aft bypass doors broke down, and all too quickly the inlet was filled with more air than it could handle. When the air pressure inside the inlet became too great, the normal shock wave was suddenly belched out of the inlet in an unstart, accompanied by an instantaneous loss of air flow to the engine, an enormous increase in drag, and a significant yaw to the side with the affected inlet. Unstarts occurred “when you least expected them—all relaxed and taking in the magnificent view from 75,000 feet,” wrote Graham in SR-71 Revealed. If the crew’s attempts to restart the inlet’s supersonic flow failed, they would have to slow their aircraft to subsonic speeds.

With a top speed of Mach 1.6, the Lockheed Martin F-35 Joint Strike Fighter has an inlet design that is far simpler than that of the Mach 3-plus SR-71; the single-engine JSF inlet cannot vary its geometry. The F-35’s engineers could get away with a less complicated design because at vehicle speeds up to about Mach 2, the shape of the inlet itself can slow down much of the supersonic air before it enters the inlet. The JSF inlet is, however, a breakthrough design: It has no diverters. Traditional fighter inlets, such as those found on the F/A-18 and F-22, have slots, slats, and moving parts to divert or channel airflow. The F-15 inlet has ramps and doors that alter its external and internal shape to adjust airflow as needed.

When a jet airplane is flying faster than Mach 1—beyond the speed of sound—the air entering the engines is moving supersonically as well. But no turbojet engine compressor—the rotating disks and blades at the face of the engine that compress the air before it is mixed with fuel—is capable of handling supersonic air flow. The job of an engine inlet is to slow incoming air to subsonic speeds before it passes through the engine.

Turbojet engines cannot digest the shock waves generated by their inlets, so a crucial role of the inlet is to keep the inevitable shock waves positioned so that they do no harm. The SR-71 Blackbird, a now-retired twin-engine reconnaissance aircraft, has an inlet design based on a cone-shaped body, or spike, that generates an oblique-angled, cone-shaped shock wave at the inlet’s entrance and a normal shock wave—one rising at a right angle from the direction of air flow—just aft of the internal inlet throat.

As the SR-71 increases its speed, the inlet varies its exterior and interior geometry to keep the cone-shaped shock wave and the normal shock wave optimally positioned. Inlet geometry is altered when the spike retracts toward the engine, approximately 1.6 inches per 0.1 Mach. At Mach 3.2, with the spike fully aft, the air-stream-capture area has increased by 112 percent and the throat area has shrunk by 54 percent.

The cone shape of the spike also incrementally reduces the speed of the incoming supersonic air without producing a drastic loss of pressure. The farther back over the cone the air moves, the more speed it bleeds off. As the slowed, but still supersonic, air continues to move farther into the inlet, the normal shock wave springs up between the inlet throat and the engine compressor—exactly where it is supposed to be. Once there, the normal shock wave slows the air passing through it to subsonic speeds, preparing it to enter the compressor.

It is a constant balancing act to keep the normal shock wave in the right position. The inlet has an internal pressure sensor, and when it detects that the pressure has grown too great, it triggers the forward bypass doors to open, expelling excess air. The inlet also has a set of aft bypass doors, controlled by the pilot. The forward and aft bypass doors work in opposition to each other: Opening the aft doors causes the forward doors to close, and when the pilot closes the aft doors, the forward doors open in turn.

During some Blackbird flights, however, the harmonious working of the spike and the forward and aft bypass doors broke down, and all too quickly the inlet was filled with more air than it could handle. When the air pressure inside the inlet became too great, the normal shock wave was suddenly belched out of the inlet in an unstart, accompanied by an instantaneous loss of air flow to the engine, an enormous increase in drag, and a significant yaw to the side with the affected inlet. Unstarts occurred “when you least expected them—all relaxed and taking in the magnificent view from 75,000 feet,” wrote Graham in SR-71 Revealed. If the crew’s attempts to restart the inlet’s supersonic flow failed, they would have to slow their aircraft to subsonic speeds.

With a top speed of Mach 1.6, the Lockheed Martin F-35 Joint Strike Fighter has an inlet design that is far simpler than that of the Mach 3-plus SR-71; the single-engine JSF inlet cannot vary its geometry. The F-35’s engineers could get away with a less complicated design because at vehicle speeds up to about Mach 2, the shape of the inlet itself can slow down much of the supersonic air before it enters the inlet. The JSF inlet is, however, a breakthrough design: It has no diverters. Traditional fighter inlets, such as those found on the F/A-18 and F-22, have slots, slats, and moving parts to divert or channel airflow. The F-15 inlet has ramps and doors that alter its external and internal shape to adjust airflow as needed.

Many other currently operational

fighters also have boundary layer diverters. Air that clings to the

surface of an aircraft in flight is known as boundary layer air, and it

tends to cause turbulence in the air flowing into the engine, especially

when it interacts with shock waves. Inlet designers try to keep out as

much boundary layer air as possible, frequently positioning the inlet

several inches away from the surface of the fuselage and its boundary

layer air and employing a duct system to whisk the undesirable air away.

(The SR-71 inlet rids itself of boundary layer air by sucking it in

through slots on the spike and passing it through ducts that exit the

nacelle.)

The F-35 inlet, however, is positioned flush against the fuselage, and just in front of the inlet opening is a raised surface, or bump, that pushes much of the boundary layer air off to the sides and away from the inlet. The bump serves another purpose: During supersonic flight, it compresses and slows the air passing over it into an oblique shock wave. The air is still moving supersonically, however, and it is slowed down to subsonic speeds after passing through a normal shock wave that forms at the mouth of the inlet. The simplicity of the JSF design makes for an inlet that requires less maintenance, reduces aircraft weight by 300 pounds, and costs $500,000 less than a traditional fighter inlet.

The F-35 inlet, however, is positioned flush against the fuselage, and just in front of the inlet opening is a raised surface, or bump, that pushes much of the boundary layer air off to the sides and away from the inlet. The bump serves another purpose: During supersonic flight, it compresses and slows the air passing over it into an oblique shock wave. The air is still moving supersonically, however, and it is slowed down to subsonic speeds after passing through a normal shock wave that forms at the mouth of the inlet. The simplicity of the JSF design makes for an inlet that requires less maintenance, reduces aircraft weight by 300 pounds, and costs $500,000 less than a traditional fighter inlet.

"Superjet" variable cycle jet engine could power future fighter aircraft

By Brian Dodson

January 6, 2013

GE Aviation is developing a revolutionary new jet engine that

aims to combine the best traits of turbojet and turbofan engines,

delivering supersonic speed capability and fuel efficiency in one

package.January 6, 2013

The new engines are being developed under the USAF ADVENT project, which is seeking 25 percent fuel saving which will in turn lead to an increase in mission capability.

There are two main species of jet engines for aviation: low-bypass turbofans, usually called turbojets, and high-bypass turbofans. Turbojets are optimized for high-performance, pushing fighter jets to above Mach 2 (and the SR-71 "Blackbird" to well over Mach 3), but pay for that performance with terrible fuel efficiency. The performance outcome of a conventional turbojet is dominated by the operation of the high-pressure engine core (compressor, combustion, turbine, and exhaust nozzle).

In contrast, high-bypass turbofans are the heavy lifters of commercial aviation, being optimized for subsonic thrust and fuel efficiency, but performing poorly at supersonic speeds. A conventional turbofan adds lower-pressure airflow from an oversized fan which is driven by the jet turbine. The fan airflow bypasses the combustion chamber, acting like a large propeller.

In an ADVENT (ADaptive VErsitile ENgine Technology) engine, the high-pressure core exhaust and the low-pressure bypass streams of a conventional turbofan are joined by a third, outer flowpath that can be opened and closed in response to flight conditions. For takeoff, the third stream is closed off to reduce the bypass ratio. This sends more of the airflow through the high-pressure core to increase thrust. When cruising, the third bypass stream is opened to increase the bypass ratio and reduce fuel consumption.

The extra bypass duct can be seen running along the top and bottom of the engine. This third duct will be opened or closed as part of a variable cycle to transform it from a strike aircraft engine to a transport-type engine. If the duct is open the bypass ratio will increase, reducing fuel burn, and increasing subsonic range by up to 40 percent, leading to 60 percent longer loiter times on target. If the ducts are closed, additional air is forced through the core and high pressure compressor, enabling thrust and speed to increase and providing world-class supersonic performance.

GE's ADVENT designs are based on new manufacturing technologies like 3-D printing of intricate cooling components and super-strong but lightweight ceramic matrix composites. These allow the manufacture of highly efficient jet engines operating at temperatures above the melting point of steel.

Engineers also designed the new engine to be easy to fly. “We want the engine to take care of itself and let the pilot focus on the mission,” says Abe Levatter, project manager at GE Aviation. “When the pilot says ‘I’m out of danger, I want to cruise home,’ the engine reconfigures itself. We take it upon ourselves to make the engine optimized for whatever the pilot wants.”

GE is now testing the engine’s core components and plans to run a full test in the middle of 2013. The video below provides additional visual description of its operation.

Source: GE Aviation

No comments:

Post a Comment