Poland bought 128 Leopard 2A4s from ex-Germany Army stocks in January 2002. They are currently operated by the 10th Armored Cavalry Brigade, based in Swietoszow. All 128 2A4s will be upgraded by 2020, while the option exists for the upgrade of an extra 14 Leopard 2A4s that were purchased by Poland in 2013 to equip the 34th Armored Cavalry Brigade, in Zagan.

The contract includes upgrades to the MBTs' turret, chassis, and other equipment to F6 level (with co-operation from subcontractor WZM Poznan), and the modernization of Poland's tank training simulators.

The upgrade will include a modernisation of the MBTs' turret armor to a level at least that of the Leopard 2A5 variant, while not exceeding a total weight of 60 tons for the Leopard 2PL. This will include a partial change of the MBT's turret armor plates, and the addition of extra armour developed by IBD. Spall liners will also be added in the crew compartment of the turret, while internal storage and stowage capabilities will be extended.

The upgrade will see the tanks retain their existing L44 120 mm gun (rather than be upgraded with the longer L55 gun), although it and its fire control system will be upgraded for compatibility with the newest DM11 and DM63-type armor-piercing ammunition. A more substantial upgrade will come in the form of new commander and gunner sights incorporating the Polish PCO KLW-1 thermal imager, while the gun and turret stabilizer systems will be changed from hydraulic to electric.

Concept image of the Leopard 2PL MBT upgrade package for the Polish Land Forces' Leopard 2A4 MBTs. Source: ZM Bumar-Labedy

Poland is the most worried that they could be next after Russia's attack on Ukraine.

By 2020, Russia has plans to produce 2,300 T-14 Armata models to replace the older T-72 and T-90 main battle tanks. The per unit cost of the T-14 is estimated to be around $8 million.

Production tests of the T-14 main battle tank–based upon the new “Armata” universal chassis system–will be completed in 2016.

SOURCES - Janes, Pew Research, The Diplomat

The Buzz

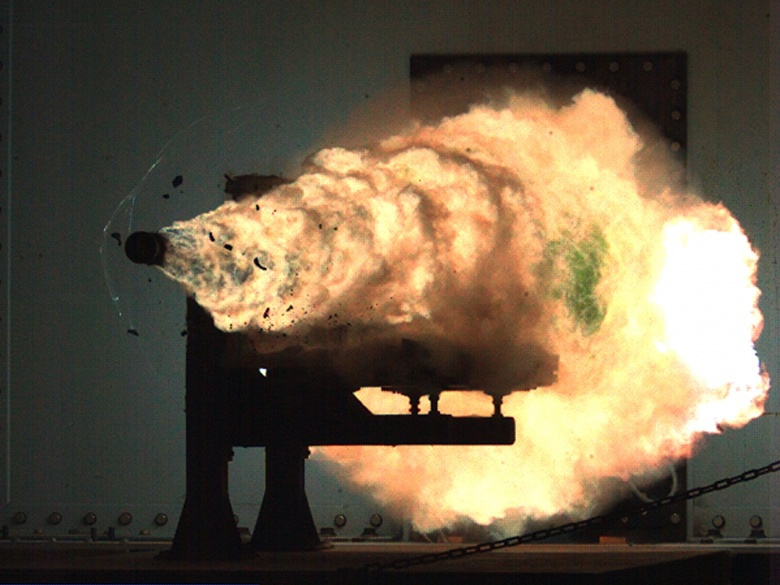

U.S. Navy: Railgun Tests to “Blow the Top Off a Mountain”

If the Navy does take the railgun out to sea on a fast transport, it will be in 2017 at the earliest. In lieu of testing the prototype rail gun in an at-sea environment, the Navy might instead proceed directly to developing an operational weapon system.

“It’s not definitely off but it’s not definitely going ahead,” Rear Adm. Peter Fanta, the Navy’s director of surface warfare, told Defense News during a Dec. 30 interview.

“Primarily because it will slow the engineering work that I have to do to get that power transference that I need to get multiple repeatable shots that I can now install in a ship. And I would frankly rather have an operational unit faster than have to take the nine months to a year it will take to set up the demo and install the systems, take the one operational [railgun] unit I have, put it on a ship, take it to sea, do a dozen shots, turn around, take it off, reinstall it into a test bed.”

Fanta said that he believes that an operational railgun is feasible within the next five years. Indeed, the Navy hopes to replace one of the 155mm gun turrets onboard the third and final Zumwalt-class destroyer Lyndon B. Johnson (DDG 1002) with a rail gun. “I don’t know if I can get there from the engineering status yet. But that’s what we continue to look at,” Fanta told Defense News.

According to Fanta, most of the key technologies behind railguns—which have until now mostly been in the realm of science fiction—have been unlocked. “It’s engineering at this point, it’s no longer science,” Fanta told Defense News. “It’s no longer the deep dark secrets of what can I do with this sort of energy. It’s engineering and how much power density can I get, how much beam quality can I get, what sort of metallurgy do I need to sustain multiple shots over multiple periods of time. The rail gun as well as the laser.”

Solving the metallurgy problem might require novel solutions—and it’s possible a solution might not exist. “My old gun barrels used to last me a few thousand rounds. Is that still the way we want to go? Other countries are solving it the other way,” Fanta told Defense News.

“Maybe if I carry four barrels and have them easily swapped out with a bunch of bosun’s mates on the [forecastle] and stick [them] in and a half-turn and you go. It’s kind of the way we do it when we overheat machine guns. The new machine guns, you got the old barrel, you stick in a new one and you keep shooting. Maybe that’s the way to go if we can’t solve the metallurgy issues that allow me to do 1,000 rounds out of a barrel.”Eventually, the Navy will have to test a full-up railgun. The trick will be to find a suitable range where the weapon can be fired at maximum range and velocity. But if the test program moves from Dahlgren, Virginia, to the White Sands Missile Range in New Mexico, it won’t be able to conduct the at-sea demo onboard a fast transport.

“I need to be able to see how this thing—for both the projectile and the gun—how it shoots at full range, which means I need both elevation and altitude and long range where I can go blow the top off a mountain someplace and not worry about someone fishing around somewhere,” Fanta told Defense News. “The discussion now [is to] move it to a better site that allows me to do full range testing, or do I go do the demo? Because it’s an either/or, it’s not both at this point.”

Dave Majumdar is the defense editor for the National Interest. You can follow him on Twitter: @davemajumdar.

Image: Wikimedia Commons/U.S. Navy.

Diesel is dead — here's what could replace it

Audi wants people to forget about diesel and focus on the company's next generation of mobility technology.

Until recently, Audi and parent company Volkswagen have focused much of their attention on the company's TDI diesel technology.

But with much of the sales of many of the VW Group's TDI models

suspended because of the ongoing emissions scandal, Audi has taken to

showing off new forms of fuel-efficient and environmental-friendly

propulsion.At last week's Consumer Electronics Show in Las Vegas, Audi proudly presented its e-tron quattro concept on which the company will base a new electric crossover that will arrive in 2018.

This week at the Detroit Auto Show, Audi unveiled the hydrogen-powered follow up called the h-tron quattro.

At the heart of the h-tron

quattro is a battery-assisted hydrogen drive system. It's a fuel-cell

powered car, which means it doesn't need a heavy battery pack to store

energy. It has a much longer range than a battery-powered car, and it

can be refueled in just minutes.

Audi isn't the only company working on hydrogen technology. BMW, Toyota, Honda, Ford, and several others are all developing their hydrogen-powered cars.

Audi isn't the only company working on hydrogen technology. BMW, Toyota, Honda, Ford, and several others are all developing their hydrogen-powered cars.

Here's how it works

The Audi system features a stack

of 330 hydrogen fuel cells capable of generating 110kw of power located

in the front of the car where the engine would normally be found. The

fuel cells are augmented by a 1.8 kWh battery pack underneath passenger

compartment that jumps in temporarily when the fuel cells need an extra

boost or when they need to recuperate.

The electricity generated by the

fuel cells power a pair of electric motors with one located between the

front wheels and the other located between the rear wheels.

(Audi) Together, the 406 lbs. ft. of torque generated by the system power to the h-tron for 0-60 mph in less that 7 seconds and an electronically limited top speed of 124 mph.

With 13.2 lbs. of

hydrogen on board spread among three tanks, the h-tron has enough juice

to travel up to 373 miles on a single fill-up. When it comes time the

fill up again, the process takes about 4 minutes.

The h-tron packed with tech. At

the heart of the h-tron's technology package is Audi's autonomous

zFAS-piloted driving system which uses a series of radar sensors,

ultrasonic sensors, a camera, and a laser scanner to take over driving

duties when called on.

(Audi) According to Audi, the zFAS system will work during stop-and-go traffic at speeds of up to 37 mph. A production version of the zFAS system is expected to be included in the next-generation Audi A8 sedan in 2017.

Like the e-tron quattro,

the h-tron is also built on Audi's new MLB evo platform which it shares

with everything from the new Audi A4 sedan to the Bentley Bentayga

SUV. Unlike with the e-tron quattro, Audi haven't said whether the

h-tron will be adapted into a production vehicle.

No comments:

Post a Comment