50 Years Ago Today: First Flight of the SR-71 Blackbird

Posted:

Updated:

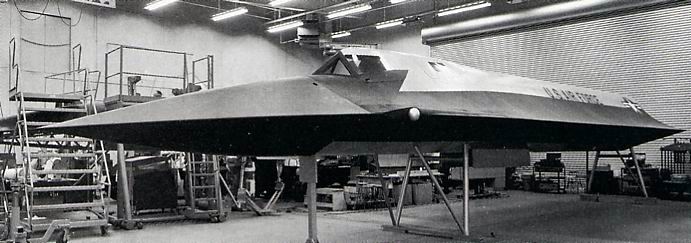

The need for such a swift strategic reconnaissance aircraft became apparent in 1960, when the Blackbird's subsonic predecessor, the U-2, was rendered a sitting duck by Russian radar. The Skunk Works, Lockheed's secretive advanced development division, succeeded in getting a test version--the A-12--off the ground at Groom Lake (a.k.a. Area 51) in April, 1962--development as head-spinningly fast as the aircraft itself.

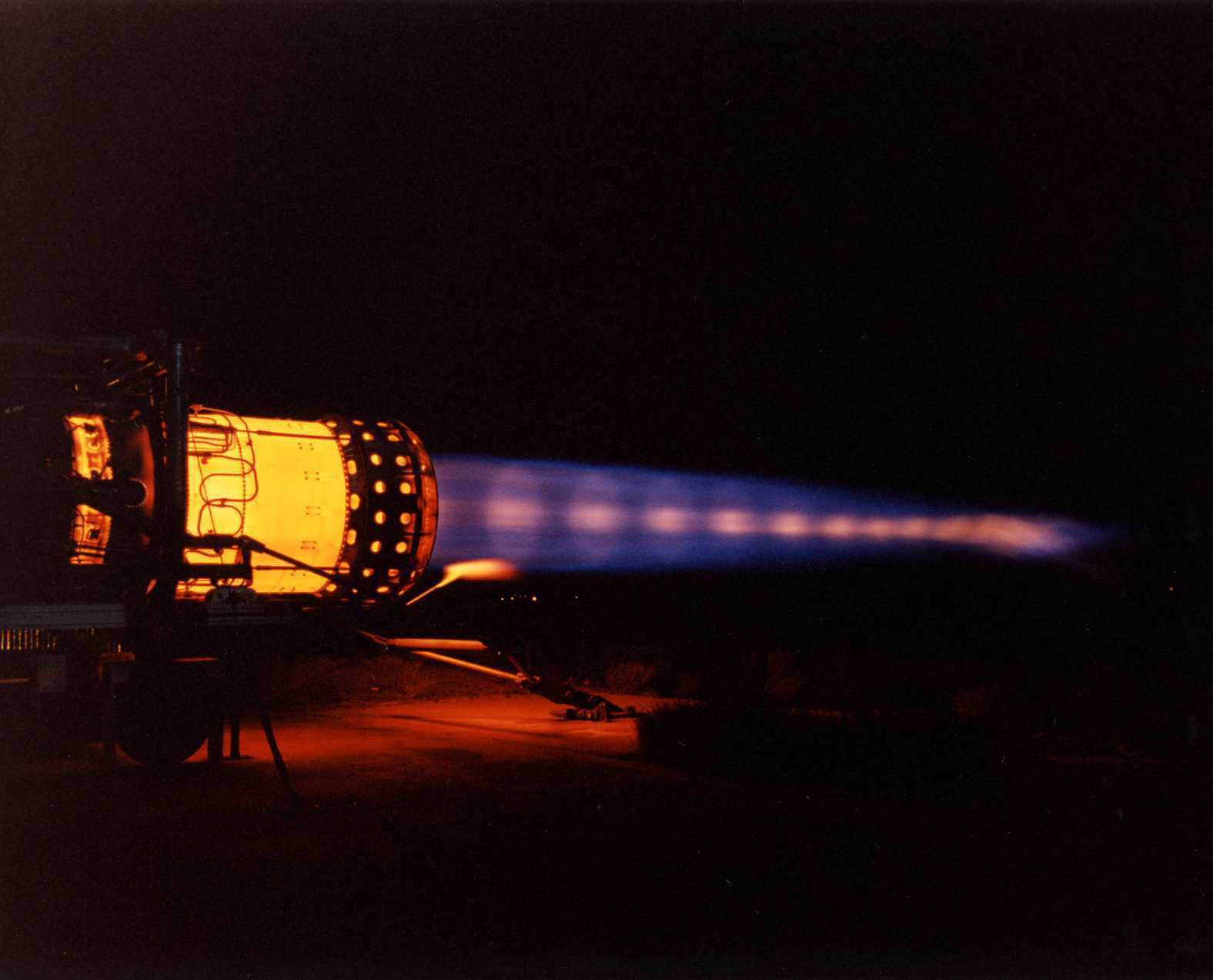

Even more astonishing was the tech, frequently summed up at the time as "black magic." Topping a long list of revolutionary components were monstrous Pratt & Whitney J58 jet engines and a design that drastically reduced radar signature, pioneering "stealth" technology. If Russian missiles ever did manage to lock on to a Blackbird, it could simply outrun them. Said a sign over the entrance to an SR-71 base, "Though I Fly Through the Valley of Death I Shall Fear No Evil--For I am at 80,000 Feet and Climbing."

The first flight of the the SR-71 took place at Air Force Plant 42 in Palmdale, California, on December 22, 1964. The first SR-71 to enter service was delivered to the 4200th Strategic Reconnaissance Wing at Beale Air Force Base in January, 1966. A total of thirty-two Blackbirds served until 1998, never succumbing to enemy action in 3,551 mission sorties whose contribution to national security can't be understated.

Palmdale, CA, Dec. 22, 1964

photos: Lockheed-Martin

From Wikipedia, the free encyclopedia

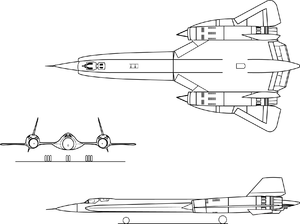

| YF-12 | |

|---|---|

|

|

| YF-12A undergoing flight testing. | |

| Role | Interceptor aircraft |

| Manufacturer | Lockheed Corporation |

| Designer | Clarence "Kelly" Johnson |

| First flight | 7 August 1963 |

| Status | Canceled |

| Primary user | United States Air Force |

| Number built | 3 |

| Unit cost |

US$15–18 million (projected)[1]

|

| Developed from | Lockheed A-12 |

| Variants | Lockheed SR-71 Blackbird |

Contents

Design and development

In the late 1950s the United States Air Force (USAF) sought a replacement for its F-106 Delta Dart interceptor. As part of the Long Range Interceptor Experimental (LRI,X) program, the North American XF-108 Rapier, an interceptor with Mach 3 speed, was selected. However, the F-108 program was canceled by the Department of Defense in September 1959.[3] During this time, Lockheed's Skunk Works was developing the A-12 reconnaissance aircraft for the Central Intelligence Agency (CIA) under the Oxcart program. Kelly Johnson, the head of Skunk Works, proposed to build a version of the A-12 named AF-12 by the company; the USAF ordered three AF-12s in mid-1960.[4]The AF-12s took the seventh through ninth slots on the A-12 assembly line; these were designated as YF-12A interceptors.[5] The main changes involved modifying the A-12's nose to accommodate the Hughes AN/ASG-18 fire-control radar originally developed for the XF-108, and the addition of the second cockpit for a crew member to operate the fire control radar for the air-to-air missile system. The modifications changed the aircraft's aerodynamics enough to require ventral fins to be mounted under the fuselage and engine nacelles to maintain stability. The four bays previously used to house the A-12's reconnaissance equipment were converted to carry Hughes AIM-47 Falcon (GAR-9) missiles.[6] One bay was used for fire control equipment.[7]

The first YF-12A flew on 7 August 1963.[6] President Lyndon B. Johnson announced the existence of the aircraft[8][9] on 24 February 1964.[10][11] The YF-12A was announced in part to continue hiding the A-12, its still-secret ancestor; any sightings of CIA/Air Force A-12s based at Area 51 in Nevada could be attributed to the well-publicized Air Force YF-12As based at Edwards Air Force Base in California.[9]

On 14 May 1965 the Air Force placed a production order for 93 F-12Bs for its Air Defense Command (ADC).[12] However, Secretary of Defense Robert McNamara would not release the funding for three consecutive years due to Vietnam War costs.[12] Updated intelligence placed a lower priority on defense of the continental US, so the F-12B was deemed no longer needed. Then in January 1968, the F-12B program was officially ended.[13]

Operational history

Air Force testing

During flight tests the YF-12As set a speed record of 2,070.101 mph (3,331.505 km/h) and altitude record of 80,257.86 ft (24,462.6 m), both on 1 May 1965,[10] and demonstrated promising results with its unique weapon system. Six successful firings of the AIM-47 missiles were completed. The last one was launched from the YF-12 at Mach 3.2 at an altitude of 74,000 ft (22,677 m) to a JQB-47E target drone 500 ft (152 m) off the ground.[14] One of the Air Force test pilots, Jim Irwin, would go on to become a NASA astronaut and walk on the Moon.The program was abandoned following the cancellation of the production F-12B, but the YF-12s continued flying for many years with the USAF and with NASA as research aircraft.

| This section requires expansion with: Fill in holes on USAF and NASA flight testing. (December 2009) |

NASA testing

Of the three YF-12As, #60-6934 was damaged beyond repair by fire at Edwards during a landing mishap on 14 August 1966; its rear half was salvaged and combined with the front half of a Lockheed static test airframe to create the only SR-71C.[16][17]

YF-12A #60-6936 was lost on 24 June 1971 due to an in-flight fire caused by a failed fuel line; both pilots ejected safely just north of Edwards AFB. YF-12A #60-06935 is the only surviving YF-12A; it was recalled from storage in 1969 for a joint USAF/NASA investigation of supersonic cruise technology, and then flown to the National Museum of the United States Air Force at Wright-Patterson Air Force Base near Dayton, Ohio on 17 November 1979.[10]

A fourth YF-12 aircraft, the "YF-12C", was actually the second SR-71A (61–7951). This SR-71A was re-designated as a YF-12C and given a fictitious serial number 60-6937 from an A-12 to maintain SR-71 secrecy. The YF-12C was loaned to NASA for propulsion testing after the loss of YF-12A (60–6936) in 1971. The YF-12C was operated by NASA until September 1978, when it was returned to the Air Force.[18]

The YF-12 had a real-field sonic-boom overpressure value between 33.5 to 52.7 N/m2 (0.7 to 1.1 lb/ft2) - below 48 was considered "low".[19]

Variants

- YF-12A

- Pre-production version. Three were built.[20]

- F-12B

- Production version of the YF-12A; canceled before production could begin.[21]

- YF-12C

- Fictitious designation for an SR-71 provided to NASA for flight testing. The YF-12 designation was used to keep SR-71 information out of the public domain.[22]

Operators

Aircraft disposition

- YF-12A

- 60-6934 – Hill Aerospace Museum, Hill AFB, Utah. Transformed into SR-71C 61-7981 after fire damage in 1966.[23]

- 60-6935 – National Museum of the U.S. Air Force, Wright-Patterson AFB, Dayton, Ohio. This aircraft has small patches in its skin, on the starboard side below the cockpit. The patches cover holes caused by the "spurs" of a crewman who had to evacuate the plane after an emergency landing.[24]

- 60-6936 – Lost, 24 June 1971

Specifications (YF-12A)

Data from Lockheed's SR-71 'Blackbird' Family[25]

General characteristics- Crew: 2

- Length: 101 ft 8 in (30.97 m)

- Wingspan: 55 ft 7 in (16.95 m)

- Height: 18 ft 6 in (5.64 m)

- Wing area: 1,795 ft² (167 m²)

- Empty weight: 60,730 lb (27,604 kg)

- Loaded weight: 124,000 lb (56,200 kg[6])

- Max. takeoff weight: 140,000 lb (63,504 kg)

- Powerplant: 2 × Pratt & Whitney J58/JTD11D-20A high-bypass-ratio turbojet with afterburner

- Dry thrust: 20,500 lbf (91.2 kN) each

- Thrust with afterburner: 31,500 lbf (140 kN) each

- Maximum speed: Mach 3.35 (2,275 mph, 3,661 km/h[6]) at 80,000 ft (24,400 m)

- Range: 3,000 mi (4,800 km)

- Service ceiling: 90,000 ft (27,400 m)

- Missiles: 3× Hughes AIM-47A air-to-air missiles located internally in fuselage bays

- Hughes AN/ASG-18 look-down/shoot-down fire control radar

See also

- Related development

- Related lists

From Wikipedia, the free encyclopedia

| J58 | |

|---|---|

|

|

| J58 engine on display at the Evergreen Aviation & Space Museum | |

| Type | Turbojet |

| Manufacturer | Pratt & Whitney |

| First run | 1958 |

| Major applications | Lockheed A-12 Lockheed SR-71 |

Contents

Design and development

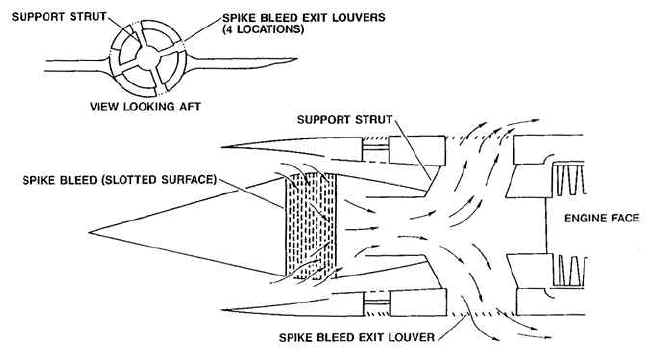

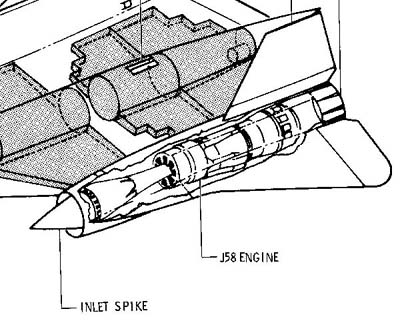

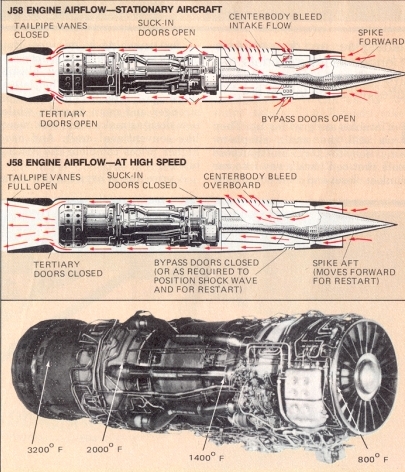

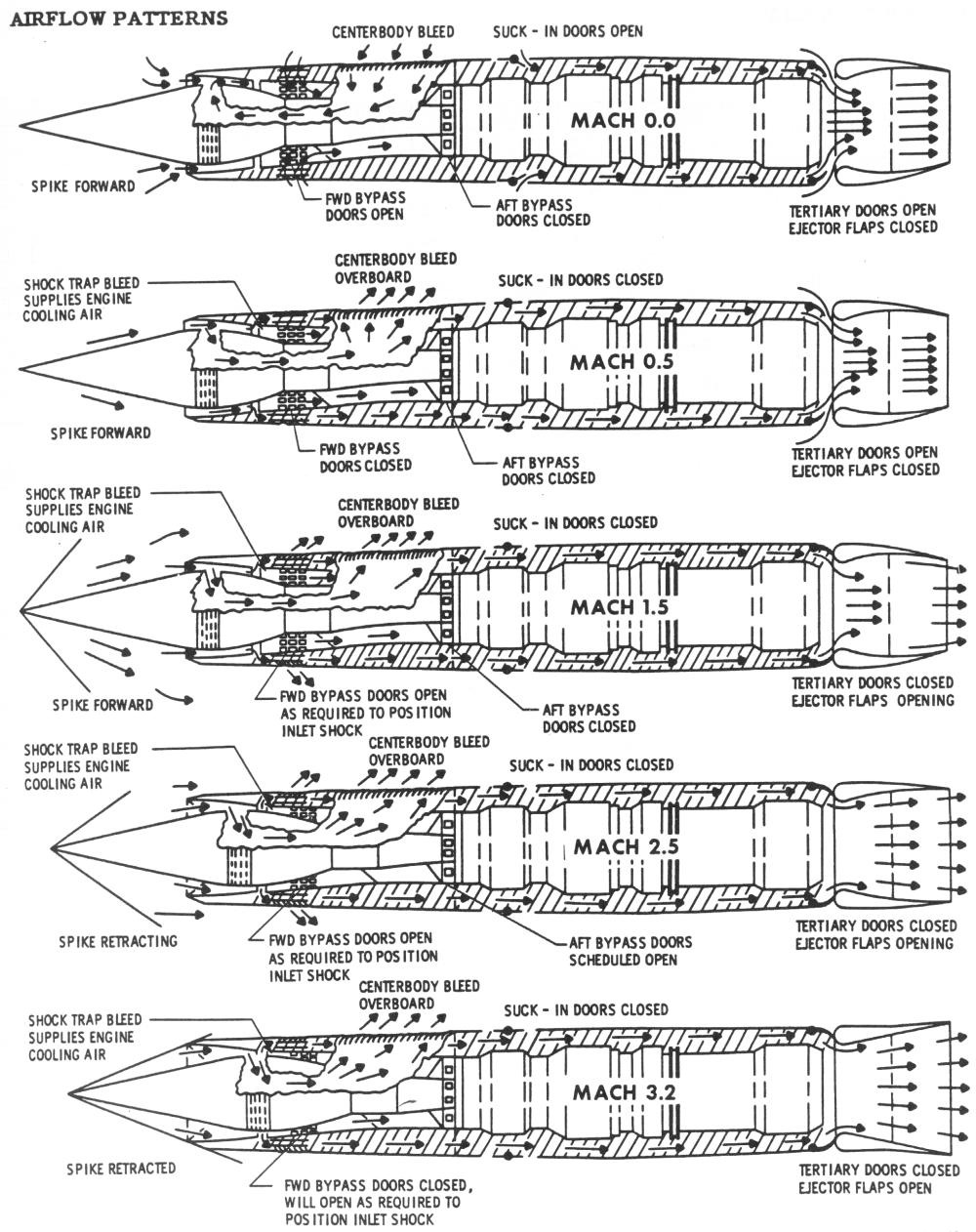

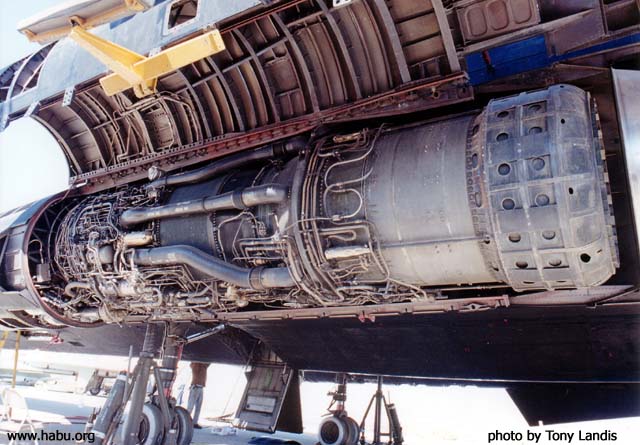

The J58 was initially developed for the US Navy to power the planned version[clarification needed] of the Martin P6M jet flying boat.[2][dead link] Upon cancellation of this aircraft, it was selected by Convair and Lockheed for their supersonic projects.[clarification needed] Other sources link its origin to the USAF's requirement for a powerplant for the WS-110A, the future XB-70 Valkyrie.[3] The J-58 produced 32,000 lbf (142 kN) of thrust. It was the first engine to be able to operate on afterburner for extended periods of time, and the first engine to be flight-qualified by the United States Air Force for Mach 3. A major feature of the J58 installation were the conical spikes in the variable-geometry inlets, which automatically moved fore and aft, controlled by an Air Inlet Computer. The spike altered the flow of supersonic air, ensuring good pressure recovery and minimum distortion at the engine inlet. The conical spikes are locked in the forward position below 30,000 feet and un-locked above that altitude. Above Mach 1.6 they are retracted approximately 1⅝ inch (4 cm ) per Mach 0.1, up to total of about 26 inches (66 cm).The engine's high operating speeds and temperatures required a new jet fuel, JP-7. Its reluctance to be ignited required triethylborane (TEB) to be injected into the engine to ignite it, and to ignite the afterburner in flight; above -5 °C TEB spontaneously ignites in contact with air. Each engine carried a nitrogen-pressurized sealed tank with 600 cm3 (20.7 ounces) of TEB, sufficient for at least 16 starts, restarts, or afterburner lights; this number was one of the limiting factors of SR-71 endurance, as after each air refueling the afterburners had to be reignited.[4] When the pilot moved the throttle from cut-off to idle position, fuel flowed into the engine, and shortly afterwards an approx. 50 cm3 (1.7 ounce) shot of TEB was injected into the combustion chamber, where it spontaneously ignited and lit the fuel with a green flash. In some conditions, however, the TEB flow was obstructed by coking deposits on the injector nozzle, hindering restart attempts. Refilling the TEB tank was a perilous task; the maintenance crew wore silver fire suits.[5] Conversely, the JP-7 fueling was so safe that some aircraft maintenance was permitted during filling. The chemical ignition was chosen instead of a conventional igniter for reliability reasons, and to reduce mechanical complexity. The TEB tank is cooled with fuel flowing around it, and contains a disk that ruptures in case of overpressure, allowing TEB and nitrogen to discharge into the afterburner.

The fuel flowing into the engine is used as a coolant to cool the engine, hydraulic fluid, oil, TEB tank, afterburner nozzle actuator control lines, air conditioning systems, and the parts of the airframe subjected to aerodynamic heating.

The engine lubricant was a silicone-based grease. It was solid at room temperature, and was preheated prior to engine start.

Modifications for Mach 3.2 flight

Introduction

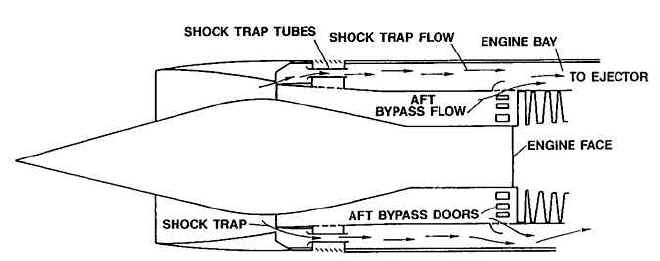

Jet engines take in their air at about Mach 0.4 irrespective of their flight speed, whether it be zero or Mach 3. Efficient operation of the engine inlet requires that it delivers the air to the engine at that speed.[6] The Lockheed Blackbird family of aircraft was designed to travel at speeds over Mach 3.2 and the slowing down of the air from this high speed to about Mach 0.4 was controlled by the intake shock cone and the shape of the downstream internal ducting(both were part of the airframe and designed by Lockheed). As air slows down, its temperature rises (to nearly 400 deg C at a flight speed of Mach 3.2) and it was this high temperature entering the compressor that prevented the J58, as originally designed, from powering the Blackbirds to Mach 3.2.[7][8] This section describes how the compressor was modified for Mach 3.2 flight to handle the aerodynamic effects of high inlet temperature. The section is based on information in U.S.Patent 3,344,606 and the SR-71 Flight Manual.[9][10]Modifications to the J58 compressor

The patent summarizes why the J58 would not work at Mach 3.2 - "As a result of the ram air temperature rise the thrust output drops because of insufficient airflow, compressor tolerance to surge (or compressor stall) is poor, and low compressor efficiency occurs resulting in high fuel consumption. Also the compressor blades are subjected to high stress from the combination of high rotational speed and flutter from rotating stall in the front stages".[9]It specifies the object of the invention - "to improve the thrust generating quality of a turbojet engine with afterburner during high supersonic flight speed operation and to improve the compressor efficiency, the compressor surge margin and the compressor blade and vane fatigue problem".[9]

It summarizes the solution - ".. by bleeding a portion of the compressor air from an intermediate compressor stage and recovering the air in the afterburner for reheating therein prior to discharge to atmosphere with the remainder of the exhaust gasses".[9]

It was found that 20% of the engine flow needed to be bled from the fourth stage to combat the effects of high compressor inlet temperature and to restore the operation of the compressor to an acceptably high efficiency and flow capacity when operating at Mach 3.2.[11]

The bleed air was returned to the engine to provide both cooling for the afterburner liner and more air for afterburner combustion.[11] It passed through six external tubes from the compressor to the afterburner.

The SR-71 Flight Manual provides information on the use of the bleed ("bleed and IGV shift schedule")[7] in terms of engine RPM and Mach number or compressor inlet temperature. It shows that this air bleed, which it calls internal, is also necessary, together with an extra bleed, which it calls external, during starting and low engine RPM.[11]

The schedule shows that variable inlet guide vanes (IGV) were also part of the compressor design. Unlike most variable IGV, where the whole vane pivots,[12] the J58 vanes had 2-position, part-span trailing edge flaps only.[11]

Like the bleed flow, the position of the flaps was also determined by the engine speed and compressor inlet temperature.[7]

A schematic view of the engine is also shown on the schedule showing the engine bleed air path from the compressor to the afterburner.[7]

Final configuration

The final configuration of the J58 for Mach 3.2 flight was that of a "turbojet with bleed air recovery", as stated in the patent. An alternative classification was a "turbojet with afterburner and compressor bleed bypass at high Mach", as stated in the Flight Manual. The engine designation was JT11-D20.[11]Contemporary solutions for flight at Mach 3

Alternative solutions to combat the adverse effects of high inlet temperature on the aerodynamic performance of the compressor were rejected by the patentee and are listed in the patent. One of those solutione was,however, used in a contemporary installation. The GE YJ93/XB-70 used a variable stator compressor to avoid front stage stall and rear stage choking.[13] Another possible solution,pre-compressor cooling, was used on the MIG-25. Water/methanol was injected from a spray mast in front of the compressor to lower the intake temperature for short durations at maximum speed,.[14] Pre-compressor cooling was also proposed for a Mach 3 reconnaissance Phantom[15] and the Mach 3+ F-106 RASCAL project[16]The complete engine installation or propulsion system

Introduction

The propulsion system consisted of the intake, engine, nacelle or secondary airflow and ejector nozzle(propelling nozzle).[17] The propulsive thrust distribution between these components changed with flight speed.at Mach 2.2 inlet 13% - engine 73% - ejector 14%

at Mach 3.0+ inlet 54% - engine 17.6% - ejector 28.4%[17]

Intake

The intake had to supply air to the engine with minimum pressure loss and distortion and at the speed dictated by the engine, namely about Mach 0.4.[6] It had to do this at all flight conditions.Nacelle airflow and ejector nozzle

The ejector nozzle, together with the engine variable nozzle, performed the reverse function of the inlet accelerating the turbine exhaust from about Mach 0.4 back up to Mach 3.[18] Mach 3 exhaust velocity is higher than Mach 3 flight velocity due to the much higher temperature in the exhaust. The nacelle airflow from the intake controlled the expansion of the hot engine exhaust in the ejector nozzle.[19] This air flowed around the engine and served also to cool the hot external parts of the engine and to purge any combustible mixtures in the event of a fuel or oil leak in the nacelle.Applications

Specification of J58-P-4

Front view of a J58 turbojet as displayed at the Imperial War Museum Duxford, Cambridgeshire, UK, alongside a Lockheed SR-71A Blackbird

| This aircraft engine article is missing some (or all) of its specifications. If you have a source, you can help Wikipedia by adding them. |

Data from [20]

General characteristics

- Type: afterburning turbojet with compressor bleed bypass

- Length: 17 ft 10 in (5.44 m) (an additional 6 in (15 cm) at max. temp.)

- Diameter: 4 ft 9 in (1.45 m)

- Dry weight: approx. 6,000 lb (2,700 kg)

Components

- Compressor: 9-stage, axial flow, single spool

- Combustors: 8 can, annular

- Turbine: two-stage axial flow

- Fuel type: JP-7

Performance

- Maximum thrust: 34,000 pounds-force (150 kN) wet, 25,000 pounds-force (110 kN) dry

- Overall pressure ratio: 6[21]

- Specific fuel consumption: 1.9 lb/(lbf·h) (54 g/(kN·s)) wet, 0.9 lb/(lbf·h) (25 g/(kN·s)) dry

- Thrust-to-weight ratio: approx. 6

- Core air flow: 450 lb/s, (200 kg/s)

See also

- Comparable engines

- General Electric GE4

- General Electric YJ93

- Rolls-Royce/Snecma Olympus 593

- Kuznetsov NK-321

- Tumansky R-15

- Reaction Engines SABRE

- Related lists

No comments:

Post a Comment