From Wikipedia, the free encyclopedia

| Anti-consumerism |

|---|

Advocates of autonomous building describe advantages that include reduced environmental impacts, increased security, and lower costs of ownership. Some cited advantages satisfy tenets of green building, not independence per se (see below). Off-grid buildings often rely very little on civil services and are therefore safer and more comfortable during civil disaster or military attacks. (Off-grid buildings would not lose power or water if public supplies were compromised for some reason.)

Most of the research and published articles concerning autonomous building focus on residential homes.

British architects Brenda and Robert Vale have said that, as of 2002,

"It is quite possible in all parts of Australia to construct a 'house with no bills', which would be comfortable without heating and cooling, which would make its own electricity, collect its own water and deal with its own waste...These houses can be built now, using off-the-shelf techniques. It is possible to build a "house with no bills" for the same price as a conventional house, but it would be (25%) smaller."[1]

Contents

History

In the 1970s, a group of activists and engineers calling themselves the New Alchemists believed the warnings of imminent resource depletion and starvation. The New Alchemists were famous for the depth of research effort placed in their projects. Using conventional construction techniques, they designed a series of "bioshelter" projects, the most famous of which was the Ark Bioshelter community for Prince Edward Island. They published the plans for all of these, with detailed design calculations and blueprints. The Ark used wind based water pumping and electricity, and was self-contained in food production. It had living quarters for people, fish tanks raising tilapia for protein, a greenhouse watered with fish water and a closed loop sewage reclamation system that recycled human waste into sanitized fertilizer for the fish tanks. As of January 2010, the successor organization to the New Alchemists has a web page up as the "New Alchemy Institute".[2] The PEI Ark has been abandoned and partially renovated several times.

The bathroom of an Earthship, featuring a recycled bottle wall

1990s architects such as William McDonough and Ken Yeang applied environmentally responsible building design to large commercial buildings, such as office buildings, making them largely self-sufficient in energy production. One major bank building (ING's Amsterdam headquarters) in the Netherlands was constructed to be autonomous and artistic as well.

Advantages

As an architect or engineer becomes more concerned with the disadvantages of transportation networks, and dependence on distant resources, their designs tend to include more autonomous elements. The historic path to autonomy was a concern for secure sources of heat, power, water and food. A nearly parallel path toward autonomy has been to start with a concern for environmental impacts, which cause disadvantages.Autonomous buildings can increase security and reduce environmental impacts by using on-site resources (such as sunlight and rain) that would otherwise be wasted. Autonomy often dramatically reduces the costs and impacts of networks that serve the building, because autonomy short-circuits the multiplying inefficiencies of collecting and transporting resources. Other impacted resources, such as oil reserves and the retention of the local watershed, can often be cheaply conserved by thoughtful designs.

Autonomous buildings are usually energy-efficient in operation, and therefore cost-efficient, for the obvious reason that smaller energy needs are easier to satisfy off-grid. But they may substitute energy production or other techniques to avoid diminishing returns in extreme conservation.

An autonomous structure is not always environmentally friendly. The goal of independence from support systems is associated with, but not identical to, other goals of environmentally responsible green building. However, autonomous buildings also usually include some degree of sustainability through the use of renewable energy and other renewable resources, producing no more greenhouse gases than they consume, and other measures.

Disadvantages

First and fundamentally, independence is a matter of degree. Complete independence is very hard or impossible to attain. For example, eliminating dependence on the electrical grid is relatively simple but growing all necessary food is a more demanding and time-consuming proposition.Living in an autonomous shelter can require one to make sacrifices in one's lifestyle choices, personal behavior, and social expectations. Even the most comfortable and technologically advanced autonomous houses may require some differences in behavior. Some people adjust easily. Others describe the experience as inconvenient, irritating, isolating, or even as an unwanted full-time job. A well-designed building can reduce this issue, but usually at the expense of reduced autonomy.

An autonomous house must be custom-built (or extensively retrofitted) to suit the climate and location. Passive solar techniques, alternative toilet and sewage systems, thermal massing designs, basement battery systems, efficient windowing, and the array of other design tactics require some degree of non-standard construction, added expense, ongoing experimentation and maintenance, and also have an effect on the psychology of the space.

The Vales, among others, have shown that living off-grid can be a practical, logical lifestyle choice—under certain conditions.[citation needed]

Systems

This section includes some minimal descriptions of methods, to give some feel for such a building's practicality, provide indexes to further information, and give a sense of modern trends.Water

A domestic rainwater harvesting system

A concrete under-floor cistern being installed.

Greywater systems reuse drained wash water to flush toilets or to water lawns and gardens. Greywater systems can halve the water use of most residential buildings; however, they require the purchase of a sump, greywater pressurization pump, and secondary plumbing. Some builders are installing waterless urinals and even composting toilets that completely eliminate water usage in sewage disposal.

The classic solution with minimal life-style changes is using a well. Once drilled, a well-foot requires substantial power. However, advanced well-foots can reduce power usage by twofold or more from older models. Well water can be contaminated in some areas. The sono arsenic filter eliminates unhealthy arsenic in well water.

However drilling a well is an uncertain activity, with aquifers depleted in some areas. It can also be expensive.

In regions with sufficient rainfall, it is often more economical to design a building to use rain, with supplementary water deliveries in a drought. Rain water makes excellent soft washwater, but needs antibacterial treatment. If used for drinking, mineral supplements or mineralization is necessary.[3]

Most desert and temperate climates get at least 250 millimetres (9.8 in) of rain per year. This means that a typical one-story house with a greywater system can supply its year-round water needs from its roof alone. In the driest areas, it might require a cistern of 30 cubic metres (7,900 US gal). Many areas average 13 millimetres (0.51 in) of rain per week, and these can use a cistern as small as 10 cubic metres (2,600 US gal).

In many areas, it is difficult to keep a roof clean enough for drinking.[4] To reduce dirt and bad tastes, systems use a metal collecting-roof and a "roof cleaner" tank that diverts the first 40 liters. Cistern water is usually chlorinated, though reverse osmosis systems provide even better quality drinking water.

Modern cisterns are usually large plastic tanks. Gravity tanks on short towers are reliable, so pump repairs are less urgent. The least expensive bulk cistern is a fenced pond or pool at ground level.

Reducing autonomy reduces the size and expense of cisterns. Many autonomous homes can reduce water use below 10 US gallons (38 L) per person per day, so that in a drought a month of water can be delivered inexpensively via truck. Self-delivery is often possible by installing fabric water tanks that fit the bed of a pick-up truck.

It can be convenient to use the cistern as a heat sink or trap for a heat pump or air conditioning system; however this can make cold drinking water warm, and in drier years may decrease the efficiency of the HVAC system.

Solar stills can efficiently produce drinking water from ditch water or cistern water, especially high-efficiency multiple effect humidification designs, which separate the evaporator(s) and condenser(s).

New technologies, like reverse osmosis can create unlimited amounts of pure water from polluted water, ocean water, and even from humid air. Water makers are available for yachts that convert seawater and electricity into potable water and brine. Atmospheric water generators extract moisture from dry desert air and filter it to pure water.

Sewage

Resource

A composting toilet

Some home sewage treatment systems use biological treatment, usually beds of plants and aquaria, that absorb nutrients and bacteria and convert greywater and sewage to clear water. This odor- and color-free reclaimed water can be used to flush toilets and water outside plants. When tested, it approaches standards for potable water. In climates that freeze, the plants and aquaria need to be kept in a small greenhouse space. Good systems need about as much care as a large aquarium.

Electric incinerating toilets turn excrement into a small amount of ash. They are cool to the touch, have no water and no pipes, and require an air vent in a wall. They are used in remote areas where use of septic tanks is limited, usually to reduce nutrient loads in lakes.

NASA's bioreactor is an extremely advanced biological sewage system. It can turn sewage into air and water through microbial action. NASA plans to use it in the manned Mars mission.

A big disadvantage of complex biological sewage treatment systems is that if the house is empty, the sewage system biota may starve to death.

Another method is NASA's urine-to-water distillation system.

Waste

Sewage handling is essential for public health. Many diseases are transmitted by poorly functioning sewage systems.The standard system is a tiled leach field combined with a septic tank. The basic idea is to provide a small system with primary sewage treatment. Sludge settles to the bottom of the septic tank, is partially reduced by anaerobic digestion, and fluid is dispersed in the leach field. The leach field is usually under a yard growing grass. Septic tanks can operate entirely by gravity, and if well managed, are reasonably safe.

Septic tanks have to be pumped periodically by a vacuum truck to eliminate non reducing solids. Failure to pump a septic tank can cause overflow that damages the leach field, and contaminates ground water. Septic tanks may also require some lifestyle changes, such as not using garbage disposals, minimizing fluids flushed into the tank, and minimizing nondigestible solids flushed into the tank. For example, septic safe toilet paper is recommended.

However, septic tanks remain popular because they permit standard plumbing fixtures, and require few or no lifestyle sacrifices.

Composting or packaging toilets make it economical and sanitary to throw away sewage as part of the normal garbage collection service. They also reduce water use by half, and eliminate the difficulty and expense of septic tanks. However, they require the local landfill to use sanitary practices.

Incinerator systems are quite practical. The ashes are biologically safe, and less than 1/10 the volume of the original waste, but like all incinerator waste, are usually classified as hazardous waste.

Some of the oldest pre-system sewage types are pit toilets, latrines, and outhouses. These are still used in many developing countries.

Storm drains

Drainage systems are a crucial compromise between human habitability and a secure, sustainable watershed. Paved areas and lawns or turf do not allow much precipitation to filter through the ground to recharge aquifers. They can cause flooding and damage in neighbourhoods, as the water flows over the surface towards a low point.Typically, elaborate, capital-intensive storm sewer networks are engineered to deal with stormwater. In some cities, such as the Victorian era London sewers or much of the old City of Toronto, the storm water system is combined with the sanitary sewer system. In the event of heavy precipitation, the load on the sewage treatment plant at the end of the pipe becomes too great to handle and raw sewage is dumped into holding tanks, and sometimes into surface water.

Autonomous buildings can address precipitation in a number of ways:

If a water absorbing swale for each yard is combined with permeable concrete streets, storm drains can be omitted from the neighbourhood. This can save more than $800 per house (1970s) by eliminating storm drains.[7] One way to use the savings is to purchase larger lots, which permits more amenities at the same cost. Permeable concrete is an established product in warm climates, and in development for freezing climates. In freezing climates, the elimination of storm drains can often still pay for enough land to construct swales (shallow water collecting ditches) or water impeding berms instead. This plan provides more land for homeowners and can offer more interesting topography for landscaping.

A green roof captures precipitation and uses the water to grow plants. It can be built into a new building or used to replace an existing roof.

Electricity

Further information: Microgeneration

Further information: Zero emissions

Wind turbine on the roof in Manchester, UK

A PV-solar system

Using a solar roof, solar cells can provide electric power. Solar roofs have the potential to be more cost-effective than retrofitted solar power, because buildings need roofs anyway. Modern solar cells last about 40 years, which makes them a reasonable investment in some areas. At a sufficient angle, solar cells are cleaned by run-off rain water and therefore have almost no life-style impact.

A number of areas that lack sun have wind. To generate power, the average autonomous house needs only one small wind generator, 5 metres or less in diameter. On a 30 metre high tower, this turbine can provide enough power to supplement solar power on cloudy days. Commercially available wind turbines use sealed, one-moving-part AC generators and passive, self-feathering blades for years of operation without service.

The largest advantage of wind power is that larger wind turbines have a lower per-watt cost than solar cells, provided there is wind. However, location is critical. Just as some locations lack sun for solar cells, some locations lack sufficient wind for an economical turbine installation. In the Great Plains of the United States a 10-metre turbine can supply enough energy to heat and cool a well-built all-electric house. Economic use in other areas requires research, and possibly a site-survey.[9]

During times of low demand, excess power can be stored in batteries for future use. However, batteries need to be replaced every few years. In many areas, battery expenses can be eliminated by attaching the building to the electric power grid and operating the power system with net metering. Utility permission is required, but such cooperative generation is legally mandated in some areas (for example, California).[9]

A grid-based building is less autonomous, but more economical and sustainable with fewer lifestyle sacrifices. In rural areas the grid's cost and impacts can be reduced by using single-wire earth return systems (for example, the MALT-system).

In areas that lack access to the grid, battery size can be reduced by including a generator to recharge the batteries during extended fogs or other low-power conditions. Auxiliary generators are usually run from propane, natural gas, or sometimes diesel. An hour of charging usually provides a day of operation. Modern residential chargers permit the user to set the charging times, so the generator is quiet at night. Some generators automatically test themselves once per week.[10][11]

Recent advances in passively stable magnetic bearings may someday permit inexpensive storage of power in a flywheel in a vacuum. Well-funded groups like Canada's Ballard Power Systems are also working to develop a "regenerative fuel cell", a device that can generate hydrogen and oxygen when power is available, and combine these efficiently when power is needed.

Earth batteries tap electric currents in the earth called telluric current. They can be installed anywhere in the ground. They provide only low voltages and current. They were used to power telegraphs in the 19th century. As appliance efficiencies increase, they may become practical.

Microbial fuel cells finally allow the generation of electricity from biomass. The plant can be chopped and converted as a whole, or it can be left alive so that waste saps from the plant can be converted by bacteria.

Heating

Schematic of an active solar heating system

Passive solar heating can heat most buildings in even the coldest climates. In colder climates, extra construction costs can be as little as 15% more than new, conventional buildings. In warm climates, those having less than two weeks of frosty nights per year, there is no cost impact.

The basic requirement for passive solar heating is that the solar collectors must face the prevailing sunlight (south in the northern hemisphere, north in the southern hemisphere), and the building must incorporate thermal mass to keep it warm in the night.

A recent, somewhat experimental solar heating system "Annualized geo solar heating" is practical even in regions that get little or no sunlight in winter.[12] It uses the ground beneath a building for thermal mass. Precipitation can carry away the heat, so the ground is shielded with 6 m skirts of plastic insulation. The thermal mass of this system is sufficiently inexpensive and large that it can store enough summer heat to warm a building for the whole winter, and enough winter cold to cool the building in summer.

In annualized geo solar systems, the solar collector is often separate from (and hotter or colder than) the living space. The building may actually be constructed from insulation, for example, straw-bale construction. Some buildings have been aerodynamically designed so that convection via ducts and interior spaces eliminates any need for electric fans.

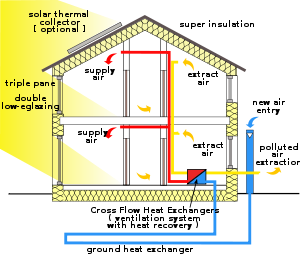

A more modest "daily solar" design is very practical. For example, for about a 15% premium in building costs, the Passivhaus building codes in Europe use high performance insulating windows, R-30 insulation, HRV ventilation, and a small thermal mass. With modest changes in the building's position, modern krypton- or argon-insulated windows permit normal-looking windows to provide passive solar heat without compromising insulation or structural strength. If a small heater is available for the coldest nights, a slab or basement cistern can inexpensively provide the required thermal mass. Passivhaus building codes in particular bring unusually good interior air quality, because the buildings change the air several times per hour, passing it though a heat exchanger to keep heat inside.

In all systems, a small supplementary heater increases personal security and reduces lifestyle impacts for a small reduction of autonomy. The two most popular heaters for ultra-high-efficiency houses are a small heat pump, which also provides air-conditioning, or a central hydronic (radiator) air heater with water recirculating from the water heater. Passivhaus designs usually integrate the heater with the ventilation system.

Earth sheltering and windbreaks can also reduce the absolute amount of heat needed by a building. Several feet below the earth, temperature ranges from 4 °C (39 °F) in North Dakota to 26 °C (79 °F),[12] in Southern Florida. Wind breaks reduce the amount of heat carried away from a building.

Rounded, aerodynamic buildings also lose less heat.

An increasing number of commercial buildings use a combined cycle with cogeneration to provide heating, often water heating, from the output of a natural gas reciprocating engine, gas turbine or stirling electric generator.[13]

Houses designed to cope with interruptions in civil services generally incorporate a wood stove, or heat and power from diesel fuel or bottled gas, regardless of their other heating mechanisms.

Electric heaters and electric stoves may provide pollution-free heat (depending on the power source), but use large amounts of electricity. If enough electricity is provided by solar panels, wind turbines, or other means, then electric heaters and stoves become a practical autonomous design.

Water heating

Further information: Solar hot water

Hot water heat recycling

units recover heat from water drain lines. They increase a building's

autonomy by decreasing the heat or fuel used to heat water. They are

attractive because they have no lifestyle changes.Current practical, comfortable domestic water-heating systems combine a solar preheating system with a thermostatic gas-powered flow-through heater, so that the temperature of the water is consistent, and the amount is unlimited. This reduces life-style impacts at some cost in autonomy.

Solar water heaters can save large amounts of fuel. Also, small changes in lifestyle, such as doing laundry, dishes and bathing on sunny days, can greatly increase their efficiency. Pure solar heaters are especially useful for laundries, swimming pools and external baths, because these can be scheduled for use on sunny days.

The basic trick in a solar water heating system is to use a well-insulated holding tank. Some systems are vacuum- insulated, acting something like large thermos bottles. The tank is filled with hot water on sunny days, and made available at all times. Unlike a conventional tank water heater, the tank is filled only when there is sunlight. Good storage makes a smaller, higher-technology collector feasible. Such collectors can use relatively exotic technologies, such as vacuum insulation, and reflective concentration of sunlight.

cogeneration systems produce hot water from waste heat. They usually get the heat from the exhaust of a generator or fuel cell.

Heat recycling, cogeneration and solar pre-heating can save 50-75% of the gas otherwise used. Also, some combinations provide redundant reliability by having several sources of heat. Some authorities advocate replacing bottled gas or natural gas with biogas. However, this is usually impractical unless live-stock are on-site. The wastes of a single family are usually insufficient to produce enough methane for anything more than small amounts of cooking.

Cooling

Annualized geo solar buildings often have buried, sloped water-tight skirts of insulation that extend 6 metres (20 ft) from the foundations, to prevent heat leakage between the earth used as thermal mass, and the surface.Less dramatic improvements are possible. Windows can be shaded in summer. Eaves can be overhung to provide the necessary shade. These also shade the walls of the house, reducing cooling costs.

Another trick is to cool the building's thermal mass at night, and then cool the building from the thermal mass during the day. It helps to be able to route cold air from a sky-facing radiator (perhaps an air heating solar collector with an alternate purpose) or evaporative cooler directly through the thermal mass. On clear nights, even in tropical areas, sky facing radiators can cool below freezing.

If a circular building is aerodynamically smooth, and cooler than the ground, it can be passively cooled by the "dome effect." Many installations have reported that a reflective or light colored dome induces a local vertical heat driven vortex that sucks cooler overhead air downward into a dome if the dome is vented properly (a single overhead vent, and peripheral vents). Some people have reported a temperature differential as high as 8 °C (15 °F) between the inside of the dome and the outside. Buckminster Fuller discovered this effect with a simple house design adapted from a grain silo, and adapted his Dymaxion house and geodesic domes to use it.

Refrigerators and air conditioners operating from the waste heat of a diesel engine exhaust, heater flue or solar collector are entering use. These use the same principles as a gas refrigerator. Normally, the heat from a flue powers an "absorptive chiller". The cold water or brine from the chiller is used to cool air or a refrigerated space.

Cogeneration is popular in new commercial buildings. In current cogeneration systems small gas turbines or stirling engines powered from natural gas produce electricity and their exhaust drives an absorptive chiller.

A truck trailer refrigerator operating from the waste heat of a tractor's diesel exhaust was demonstrated by NRG Solutions, Inc. NRG developed a hydronic ammonia gas heat exchanger and vaporizer, the two essential new, not commercially available components of a waste heat driven refrigerator.

A similar scheme (multiphase cooling) can be by a multistage evaporative cooler. The air is passed through a spray of salt solution to dehumidify it, then through a spray of water solution to cool it, then another salt solution to dehumidify it again. The brine has to be regenerated, and that can be done economically with a low temperature solar still. Multiphase evaporative coolers can lower the air's temperature by 50 °F (28 °C), and still control humidity. If the brine regenerator uses high heat, they also partially sterilise the air.

If enough electric power is available, cooling can be provided by conventional air conditioning using a heat pump.

Food production

Food production has often been included in historic autonomous projects to provide security.[14] Skilled, intensive gardening can support an adult from as little as 100 square meters of land per person,[15][16] possibly requiring the use of organic farming and aeroponics. Some proven intensive, low-effort food-production systems include urban gardening (indoors and outdoors). Indoor cultivation may be set up using hydroponics, while outdoor cultivation may be done using permaculture, forest gardening, no-till farming, and do nothing farming.Greenhouses are also sometimes included.[14][17] Sometimes they are also outfitted with irrigation systems or heat sink-systems which can respectively irrigate the plants or help to store energy from the sun and redistribute it at night (when the greenhouses starts to cool down).[14][18]

Microgeneration

From Wikipedia, the free encyclopedia

| Part of a series about |

| Sustainable energy |

|---|

|

| Energy conservation |

|

| Renewable energy |

| Sustainable transport |

Contents

Technologies and set-up

Microgeneration technologies include small-scale wind turbines, micro hydro, solar PV systems, microbial fuel cells, ground source heat pumps, and micro combined heat and power installations.[1]The power plant

In addition to the electricity production plant (e.g. wind turbine and solar panel), infrastructure for energy storage and power conversion and a hook-up to the regular electricity grid is usually needed and/or foreseen. Although a hookup to the regular electricity grid is not essential, it helps to decrease costs by allowing financial recompensation schemes. In the developing world however, the start-up cost for this equipment is generally too high, thus leaving no choice but to opt for alternative set-ups.[2]Extra equipment needed besides the power plant

A complete PV-solar system

Energy storage apparatus

A major issue with off-grid solar and wind systems is that the power is often needed when the sun is not shining or when the wind is calm, this is generally not required for purely grid-connected systems:- a series of deep cycle, stationary or sealed maintenance free batteries (the most common solution) [4]

- a charge controller for charging the batteries or other energy storage

- an inverter or grid-interactive inverter. The whole is also sometimes referred to as "power conditioning equipment"

Safety equipment

- groundings, transfer switches or isolator switches and surge protector. The whole is also sometimes referred to as "safety equipment"

- battery meters (for charging rate and voltage), and meters for power consumption and electricity provision to the regular power grid

Small-scale (DIY) generation system

Wind turbine specific

With wind turbines, hydroelectric plants, ... the extra equipment needed [8][9][10][11] is more or less the same as with PV-systems (depending on the type of wind turbine used,[12] yet also include:- a manual disconnect switch

- foundation for the tower

- grounding system

- shutoff and/or dummy-load devices for use in high wind when power generated exceeds current needs and storage system capacity.

Vibro-wind power

A new wind energy technology is being developed that converts energy from wind energy vibrations to electricity. This energy, called Vibro-Wind technology, can use winds of less strength than normal wind turbines, and can be placed in almost any location.A prototype consisted of a panel mounted with oscillators made out of pieces of foam. The conversion from mechanical to electrical energy is done using a piezoelectric transducer, a device made of a ceramic or polymer that emits electrons when stressed. The building of this prototype was led by Francis Moon, professor of mechanical and aerospace engineering at Cornell University. Moon's work in Vibro-Wind Technology was funded by the Atkinson Center for a Sustainable Future at Cornell.[13]

Possible set-ups

Several microgeneration set-ups are possible. These are:- Off-the-grid set-ups which include:

- Off-the grid set-ups without energy storage (e.g., battery, ...)

- Off-the grid set-ups with energy storage (e.g., battery, ...)

- Battery charging stations [14]

- Grid-connected set-ups which include:

- Grid connected with backup to power critical loads

- Grid-connected set-ups without financial recompensation scheme

- Grid-connected set-ups with net metering

- Grid connected set-ups with net purchase and sale [15]

Costs

Depending on the set-up chosen (financial recompensation scheme, power plant, extra equipment), prices may vary. According to Practical Action, microgeneration at home which uses the latest in cost saving-technology (wiring harnesses, ready boards, cheap DIY-power plants, e.g. DIY wind turbines) the household expenditure can be extremely low-cost. In fact, Practical Action mentions that many households in farming communities in the developing world spend less than $1 for electricity per month. .[16] However, if matters are handled less economically (using more commercial systems/approaches), costs will be dramatically higher. In most cases however, financial advantage will still be done using microgeneration on renewable power plants; often in the range of 50-90% [17] as local production has no electricity transportation losses on long distance power lines or energy losses from the Joule effect in transformers where in general 8-15% of the energy is lost.[18]In the UK, the government offers both grants and feedback payments to help businesses, communities and private homes to install these technologies. Businesses can write the full cost of installation off against taxable profits whilst homeowners receive a flat rate grant or payments per kW h of electricity generated and paid back into the national grid. Community organisations can also receive up to £200,000 in grant funding.[19]

In the UK, the Microgeneration Certification Scheme provides approval for Microgeneration Installers and Products which is a mandatory requirement of funding schemes such as the Feed in Tariffs and Renewable Heat Incentive.

Grid parity

Grid parity (or socket parity) occurs when an alternative energy source can generate electricity at a levelized cost (LCoE) that is less than or equal to the price of purchasing power from the electricity grid. Reaching grid parity is considered to be the point at which an energy source becomes a contender for widespread development without subsidies or government support. It is widely believed that a wholesale shift in generation to these forms of energy will take place when they reach grid parity.Grid parity has been reached in some locations with on-shore wind power around 2000, and with solar power it was achieved for the first time in Spain in 2013.[20][21][22]

Microgeneration can dynamically balance the supply and demand for electric power, by producing more power during periods of high demand and high grid prices, and less power during periods of low demand and low grid prices. This "hybridized grid" allows both microgeneration systems and large power plants to operate with greater energy efficiency and cost effectiveness than either could alone.

Domestic self-sufficiency

Further information: Autonomous building

See also: Earthship and Off-the-grid

Horizontal Axis Micro-Windmill in Lahore, 1000Watt Rated Output

A small Quietrevolution QR5 Gorlov type

vertical axis wind turbine in Bristol, England. Measuring 3 m in

diameter and 5 m high, it has a nameplate rating of 6.5 kW to the grid.

Passive solar water heating is another effective method of utilizing solar power. The simplest method is the solar (or a black plastic) bag. Set between 1 and 5 gallons out in the sun and allow to heat. Perfect for a quick warm shower.[26]

The ‘breadbox’ heater can be constructed easily with recycled materials and basic building experience. Consisting of a single or array of black tanks mounted inside a sturdy box insulated on the bottom and sides. The lid, either horizontal or angled to catch the most sun, should be well sealed and of a transparent glazing material (glass, fiberglass, or high temp resistant molded plastic). Cold water enters the tank near the bottom, heats and rises to the top where it is piped back into the home.[26]

Ground source heat pumps exploit stable ground temperatures by benefiting from the thermal energy storage capacity of the ground. Typically ground source heat pumps have a high initial cost and are difficult to install by the average homeowner. They use electric motors to transfer heat from the ground with a high level of efficiency. The electricity may come from renewable sources or from external non-renewable sources.

Fuel

Biodiesel is an alternative fuel that can power diesel engines and can be used for domestic heating. Numerous forms of biomass, including soybeans, peanuts, and algae (which has the highest yield), can be used to make biodiesel. Recycled vegetable oil (from restaurants) can also be converted into biodiesel.Biogas is another alternative fuel, created from the waste product of animals. Though less practical for most homes, a farm environment provides a perfect place to implement the process. By mixing the waste and water in a tank with space left for air, methane produces naturally in the airspace. This methane can be piped out and burned, and used for a cookfire.

The biogaspro digester provides an easily installed digester suitable for small farms or even large homes. Groups of homes can possible group together to use a digester [27]

Government policy

Policymakers were accustomed to an energy system based on big, centralised projects like nuclear or gas-fired power stations. A change of mindsets and incentives are bringing microgeneration into the mainstream. Planning regulations may also require streamlining to facilitate the retrofitting of microgenerating facilities onto homes and buildings.Most of developed countries, including Canada (Alberta), the United Kingdom, Germany, Poland, Israel[28] and USA have laws allowing microgenerated electricity to be sold into the national grid.

Alberta, Canada

In January 2009, the Government of Alberta‘s Micro-Generation Regulation came into effect, setting rules that allow Albertans to generate their own environmentally friendly electricity and receive credit for any power they send into the electricity grid.Poland

In December 2014, the Polish government will vote on a bill which calls for microgeneration, as well as large scale wind farms in the Baltic Sea as a solution to cut back on co2 emissions from the country's coal plants as well as to reduce Polish dependence on Russian gas. Under the terms of the new bill, individuals and small businesses which generate up to 40 kW of 'green' energy will receive 100% of market price for any electricity they feed back into the grid, and businesses who set up large-scale offshore wind farms in the Baltic will be eligible for subsidization by the state. Costs of implementing these new policies will be offset by the creation of a new tax on non-sustainable energy use. [29]United States

The United States has inconsistent energy generation policies across its 50 states. State energy policies and laws may vary significantly with location. Some states have imposed requirements on utilities that a certain percentage of total power generation be from renewable sources. For this purpose, renewable sources include wind, hydroelectric, and solar power whether from large or microgeneration projects. Further, in some areas transferrable "renewable source energy" credits are needed by power companies to meet these mandates. As a result, in some portions of the United States, power companies will pay a portion of the cost of renewable source microgeneration projects in their service areas. These rebates are in addition to any Federal or State renewable-energy income-tax credits that may be applicable. In other areas, such rebates may differ or may not be available.United Kingdom

The UK Government published its Microgeneration Strategy[30] in March 2006, although it was seen as a disappointment by many commentators.[31] In contrast, the Climate Change and Sustainable Energy Act 2006 has been viewed as a positive step.[32] To replace earlier schemes, the Department of Trade and Industry (DTI) launched the Low Carbon Buildings Programme in April 2006, which provided grants to individuals, communities and businesses wishing to invest in microgenerating technologies. These schemes have been replaced in turn by new proposals from the Department for Energy and Climate Change (DECC) for clean energy cashback via Feed-In Tariffs [33] for generating electricity from April 2010 and the Renewable Heat Incentive [34] for generating renewable heat from 28 November 2011.Feed-In Tariffs are intended to incentivise small-scale (less than 5MW), low-carbon electricity generation. These feed-in tariffs work alongside the Renewables Obligation (RO), which will remain the primary mechanism to incentivise deployment of large-scale renewable electricity generation. The Renewable Heat Incentive (RHI) in intended to incentivise the generation of heat from renewable sources. They also currently offer up to 21p per kWh from December 2011 in the Tariff for photovoltaics plus another 3p for the Export Tariff - an overall figure which could see a household earning back double what they currently pay for their electricity.[35]

On 31 October 2011, the government announced a sudden cut in the feed-in tariff from 43.3p/kWh to 21p/kWh with the new tariff to apply to all new solar PV installations with an eligibility date on or after 12 December 2011.[36]

Prominent British politicians who have announced they are fitting microgenerating facilities to their homes include the Conservative party leader, David Cameron, and the Labour Science Minister, Malcolm Wicks. These plans included small domestic sized wind turbines. Cameron, before becoming Prime Minister in the 2010 general elections, had been asked during an interview on BBC One’s The Politics Show on October 29, 2006, if he would do the same should he get to 10 Downing Street. “If they’d let me, yes,” he replied.[37]

In the December 2006 Pre-Budget Report[38] the government announced that the sale of surplus electricity from installations designed for personal use, would not be subject to Income Tax. Legislation to this effect has been included in the Finance Bill 2007.[39]

In popular culture

Microgeneration has been popularised by several movies, TV-shows, and magazines. Movies such as The Mosquito Coast, Jericho, The Time Machine, and Beverly Hills Family Robinson have done a great deal in raising interest to the general public. More specialised magazines such as OtherPower and Home Power give more practical advice and guidance.[40] Websites such as Instructables and Practical Action are increasing the popularity of microgeneration by proposing DIY-solutions which can decrease the cost of microgeneration.Solar air conditioning

Solar air conditioning refers to any air conditioning (cooling) system that uses solar power.

This can be done through passive solar, solar thermal energy conversion and photovoltaic conversion (sunlight to electricity). The U.S. Energy Independence and Security Act of 2007[1] created 2008 through 2012 funding for a new solar air conditioning research and development program, which should develop and demonstrate multiple new technology innovations and mass production economies of scale. Solar air conditioning might play an increasing role in zero-energy and energy-plus buildings design.[who?]

This can be done through passive solar, solar thermal energy conversion and photovoltaic conversion (sunlight to electricity). The U.S. Energy Independence and Security Act of 2007[1] created 2008 through 2012 funding for a new solar air conditioning research and development program, which should develop and demonstrate multiple new technology innovations and mass production economies of scale. Solar air conditioning might play an increasing role in zero-energy and energy-plus buildings design.[who?]

Contents

History

In the late 19th century, the most common fluid for absorption cooling was a solution of ammonia and water. Today, the combination of lithium bromide and water is also in common use. One end of the system of expansion/condensation pipes is heated, and the other end gets cold enough to make ice. Originally, natural gas was used as a heat source in the late 19th century. Today, propane is used in recreational vehicle absorption chiller refrigerators. Hot water solar thermal energy collectors can also be used as the modern "free energy" heat source.Photovoltaic (PV) solar cooling

Main article: Photovoltaic electricity

Photovoltaics can provide the power for any type of electrically powered cooling be it conventional

compressor-based or adsorption/absorption-based, though the most common

implementation is with compressors. For small residential and small

commercial cooling (less than 5 MWh/a)

PV-powered cooling has been the most frequently implemented solar

cooling technology. The reason for this is debated, but commonly

suggested reasons include incentive structuring, lack of

residential-sized equipment for other solar-cooling technologies, the

advent of more efficient electrical coolers, or ease of installation

compared to other solar-cooling technologies (like radiant cooling).Since PV cooling's cost effectiveness depends largely on the cooling equipment and given the poor efficiencies in electrical cooling methods until recently it has not been cost effective without subsidies. Using more efficient electrical cooling methods and allowing longer payback schedules is changing that scenario.

For example, a 100,000 BTU U.S. Energy Star rated[note 1] air conditioner with a high seasonal energy efficiency ratio (SEER) of 14 requires around 7 kW of electric power for full cooling output on a hot day. This would require over a 20 kW solar photovoltaic electricity generation system with storage.

A solar-tracking 7 kW photovoltaic system would probably have an installed price well over $20,000 USD (with PV equipment prices currently falling at roughly 17% per year). Infrastructure, wiring, mounting, and NEC code costs may add up to an additional cost; for instance a 3120 watt solar panel grid tie system has a panel cost of $0.99/watt peak, but still costs ~$2.2/watt hour peak. Other systems of different capacity cost even more, let alone battery backup systems, which cost even more.

A more efficient air conditioning system would require a smaller, less-expensive photovoltaic system. A high-quality geothermal heat pump installation can have a SEER in the range of 20 (±). A 100,000 BTU SEER 20 air conditioner would require less than 5 kW while operating.

Newer and lower power technology including reverse inverter DC heat pumps can achieve SEER ratings up to 26.

There are new non-compressor-based electrical air conditioning systems with a SEER above 20 coming on the market. New versions of phase-change indirect evaporative coolers use nothing but a fan and a supply of water to cool buildings without adding extra interior humidity (such as at McCarran Airport Las Vegas Nevada). In dry arid climates with relative humidity below 45% (about 40% of the continental U.S.) indirect evaporative coolers can achieve a SEER above 20, and up to SEER 40. A 100,000 BTU indirect evaporative cooler would only need enough photovoltaic power for the circulation fan (plus a water supply).

A less-expensive partial-power photovoltaic system can reduce (but not eliminate) the monthly amount of electricity purchased from the power grid for air conditioning (and other uses). With American state government subsidies of $2.50 to $5.00 USD per photovoltaic watt,[2] the amortized cost of PV-generated electricity can be below $0.15 per kWh. This is currently cost effective in some areas where power company electricity is now $0.15 or more. Excess PV power generated when air conditioning is not required can be sold to the power grid in many locations, which can reduce (or eliminate) annual net electricity purchase requirement. (See Zero-energy building)

Superior energy efficiency can be designed into new construction (or retrofitted to existing buildings). Since the U.S. Department of Energy was created in 1977, their Weatherization Assistance Program[3] has reduced heating-and-cooling load on 5.5 million low-income affordable homes an average of 31%. A hundred million American buildings still need improved weatherization. Careless conventional construction practices are still producing inefficient new buildings that need weatherization when they are first occupied.

It is fairly simple to reduce the heating-and-cooling requirement for new construction by one half. This can often be done at no additional net cost, since there are cost savings for smaller air conditioning systems and other benefits.

Geothermal cooling

Earth sheltering or Earth cooling tubes can take advantage of the ambient temperature of the Earth to reduce or eliminate conventional air conditioning requirements. In many climates where the majority of humans live, they can greatly reduce the buildup of undesirable summer heat, and also help remove heat from the interior of the building. They increase construction cost, but reduce or eliminate the cost of conventional air conditioning equipment.Earth cooling tubes are not cost effective in hot humid tropical environments where the ambient Earth temperature approaches human temperature comfort zone. A solar chimney or photovoltaic-powered fan can be used to exhaust undesired heat and draw in cooler, dehumidified air that has passed by ambient Earth temperature surfaces. Control of humidity and condensation are important design issues.

A geothermal heat pump uses ambient Earth temperature to improve SEER for heat and cooling. A deep well recirculates water to extract ambient Earth temperature (typically at 2 gallons of water per ton per minute). These "open loop" systems were the most common in early systems, however water quality could cause damage to the coils in the heat pump and shorten the life of the equipment. Another method is a closed loop system, in which a loop of tubing is run down a well or wells, or in trenches in the lawn, to cool an intermediate fluid. When wells are used, they are back-filled with Bentonite or another grout material to ensure good thermal conductivity to the earth.

In the past the fluid of choice was a 50/50 mixture of propylene glycol because it is non-toxic unlike ethylene glycol (which is used in car radiators). Propylene glycol is viscous, and would eventually gum up some parts in the loop(s), so it has fallen out of favor. Today, the most common transfer agent is a mixture of water and ethyl alcohol (ethanol).

Ambient earth temperature is much lower than peak summer air temperature, and much higher than the lowest extreme winter air temperature. Water is 25 times more thermally conductive than air, so it is much more efficient than an outside air heat pump, (which becomes less effective when the outside temperature drops in Winter).

The same type of geothermal well can be used without a heat pump but with greatly diminished results. Ambient Earth temperature water is pumped through a shrouded radiator (like an automobile radiator). Air is blown across the radiator, which cools without a compressor-based air conditioner. Photovoltaic solar electric panels produce electricity for the water pump and fan, eliminating conventional air-conditioning utility bills. This concept is cost-effective, as long as the location has ambient Earth temperature below the human thermal comfort zone (not the tropics).

Solar open-loop Air Conditioning using desiccants

Air can be passed over common, solid desiccants (like silica gel or zeolite) or liquid desiccants (like lithium bromide/chloride) to draw moisture from the air to allow an efficient mechanical or evaporative cooling cycle. The desiccant is then regenerated by using solar thermal energy to dehumidfy, in a cost-effective, low-energy-consumption, continuously repeating cycle.[4] A photovoltaic system can power a low-energy air circulation fan, and a motor to slowly rotate a large disk filled with desiccant.Energy recovery ventilation systems provide a controlled way of ventilating a home while minimizing energy loss. Air is passed through an "enthalpy wheel" (often using silica gel) to reduce the cost of heating ventilated air in the winter by transferring heat from the warm inside air being exhausted to the fresh (but cold) supply air. In the summer, the inside air cools the warmer incoming supply air to reduce ventilation cooling costs.[5] This low-energy fan-and-motor ventilation system can be cost-effectively powered by photovoltaics, with enhanced natural convection exhaust up a solar chimney - the downward incoming air flow would be forced convection (advection).

A desiccant like calcium chloride can be mixed with water to create an attractive recirculating waterfall, that dehumidifies a room using solar thermal energy to regenerate the liquid, and a PV-powered low-rate water pump[6]

Active solar cooling wherein solar thermal collectors provide input energy for a desiccant cooling system. There are several commercially available systems that blow air through a desiccant impregnated medium for both the dehumidification and the regeneration cycle. The solar heat is one way that the regeneration cycle is powered. In theory packed towers can be used to form a counter-current flow of the air and the liquid desiccant but are not normally employed in commercially available machines. Preheating of the air is shown to greatly enhance desiccant regeneration. The packed column yields good results as a dehumidifier/regenerator, provided pressure drop can be reduced with the use of suitable packing.[7]

Passive solar cooling

Main articles: Passive cooling and Passive solar

In this type of cooling solar thermal energy is not used directly to

create a cold environment or drive any direct cooling processes.

Instead, solar building design aims at slowing the rate of heat transfer

into a building in the summer, and improving the removal of unwanted

heat. It involves a good understanding of the mechanisms of heat transfer: heat conduction, convective heat transfer, and thermal radiation, the latter primarily from the sun.For example, a sign of poor thermal design is an attic that gets hotter in summer than the peak outside air temperature. This can be significantly reduced or eliminated with a cool roof or a green roof, which can reduce the roof surface temperature by 70 °F (40 °C) in summer. A radiant barrier and an air gap below the roof will block about 97% of downward radiation from roof cladding heated by the sun.

Passive solar cooling is much easier to achieve in new construction than by adapting existing buildings. There are many design specifics involved in passive solar cooling. It is a primary element of designing a zero energy building in a hot climate.

Solar closed-loop absorption cooling

Main article: Absorption heat pump

The following are common technologies in use for solar thermal closed-loop air conditioning.- Absorption: NH

3/H

2O or Ammonia/Water - Absorption: Water/Lithium Bromide

- Absorption: Water/Lithium Chloride

- Adsorption: Water/Silica Gel or Water/Zeolite

- Adsorption: Methanol/Activated Carbon[8]

Solar thermal energy can be used to efficiently cool in the summer, and also heat domestic hot water and buildings in the winter. Single, double or triple iterative absorption cooling cycles are used in different solar-thermal-cooling system designs. The more cycles, the more efficient they are. Absorption chillers operate with less noise and vibration than compressor-based chillers, but their capital costs are relatively high.[10]

Efficient absorption chillers nominally require water of at least 190 °F (88 °C). Common, inexpensive flat-plate solar thermal collectors only produce about 160 °F (71 °C) water. High temperature flat plate, concentrating or evacuated tube collectors are needed to produce the higher temperature water required. In large scale installations there are several projects successful both technical and economical in operation worldwide including, for example, at the headquarters of Caixa Geral de Depósitos in Lisbon with 1,579 square metres (17,000 sq ft) solar collectors and 545 kW cooling power or on the Olympic Sailing Village in Qingdao/China. In 2011 the most powerful plant at Singapore's new constructed United World College will be commissioned (1500 kW).

These projects have shown that flat plate solar collectors specially developed for temperatures over 200 °F (93 °C) (featuring double glazing, increased backside insulation, etc.) can be effective and cost efficient.[11] Where water can be heated well above 190 °F (88 °C), it can be stored and used when the sun is not shining.

The Audubon Environmental Center at the Ernest E. Debs Regional Park in Los Angeles has an example solar air conditioning installation,[12][13] which failed fairly soon after commissioning and is no longer being maintained.[citation needed] The Southern California Gas Co. (The Gas Company) is also testing the practicality of solar thermal cooling systems at their Energy Resource Center (ERC) in Downey, California. Solar Collectors from Sopogy and Cogenra were installed on the rooftop at the ERC and are producing cooling for the building’s air conditioning system.[14] Masdar City in the United Arab Emirates is also testing a double-effect absorption cooling plant using Sopogy parabolic trough collectors,[15] Mirroxx Fresnel array and TVP Solar high-vacuum solar thermal panels.[16]

For 150 years, absorption chillers have been used to make ice (before the electric light bulbs were invented).[17] This ice can be stored and used as an "ice battery" for cooling when the sun is not shining, as it was in the 1995 Hotel New Otani Tokyo in Japan.[18] Mathematical models are available in the public domain for ice-based thermal energy storage performance calculations.[19]

The ISAAC Solar Icemaker is an intermittent solar ammonia-water absorption cycle. The ISAAC uses a parabolic trough solar collector and a compact and efficient design to produce ice with no fuel or electric input, and with no moving parts.[20]

Providers of solar cooling systems include ChillSolar,[21] SOLID,[22] Sopogy,[23] Cogenra,[24] Mirroxx [25] and TVP Solar [26] for commercial installations and ClimateWell,[27] Fagor-Rotartica, SorTech and Daikin mostly for residential systems. Cogenra uses solar co-generation to produce both thermal and electric energy that can be used for cooling.[28]

Zero-energy buildings

Goals of zero-energy buildings include sustainable, green building technologies that can significantly reduce, or eliminate, net annual energy bills. The supreme achievement is the totally off-the-grid autonomous building that does not have to be connected to utility companies. In hot climates with significant degree days of cooling requirement, leading-edge solar air conditioning will be an increasingly important critical success factor.Solar-powered refrigerator

From Wikipedia, the free encyclopedia

(Redirected from Solar powered refrigerator)

This

article is about sealed gas-exchange refrigerators which use solar

power. For evaporative devices which use ambient heat, see pot-in-pot refrigerator.

A solar-powered refrigerator is a refrigerator which runs on energy directly provided by sun, and may include photovoltaic or solar thermal energy.Solar-powered refrigerators are able to keep perishable goods such as meat and dairy cool in hot climates, and are used to keep much needed vaccines at their appropriate temperature to avoid spoilage.

Solar-powered refrigerators may be most commonly used in the developing world to help mitigate poverty and climate change.

Contents

Rationale

There is environmental concern regarding conventional refrigeration technologies including contribution to ozone layer depletion and global warming. Refrigerators which contain ozone depleting and global warming substances such as chlorofluorocarbons (CFCs), in their insulation foam or their refrigerant cycle, are the most harmful. After CFCs were banned in the 1980s, they were replaced with substances such as hydrochlorofluorocarbons (HCFCs), which are ozone-depleting substances and hydrofluorocarbons (HFCs). Both are environmentally destructive as potential global warming chemicals. If a conventional refrigerator is inefficient or used inefficiently, it will also contribute more to global warming than a highly efficient refrigerator. The use of solar energy to power refrigeration strives to minimize the negative impacts refrigerators have on the environment.[1][2]History

In 1878, at the Universal Exhibition in Paris, Augustin Mouchot displayed Mouchot's engine and won a Gold Medal in Class 54 for his works, most notably the production of ice using concentrated solar heat."In developed countries, plug-in refrigerators with backup generators store vaccines safely, but in developing countries, where electricity supplies can be unreliable, alternative refrigeration technologies are required".[3] Solar fridges were introduced in the developing world to cut down on the use of kerosene or gas-powered absorption refrigerated coolers which are the most common alternatives. They are used for both vaccine storage and household applications in areas without reliable electrical supply because they have poor or no grid electricity at all.[2][4] They burn a liter of kerosene per day therefore requiring a constant supply of fuel which is costly and smelly, and are responsible for the production of large amounts of carbon dioxide.[3] They can also be difficult to adjust which can result in the freezing of medicine. The use of Kerosene as a fuel is now widely discouraged for three reasons: Recurrent cost of fuel, difficulty of maintaining accurate temperature and risk of causing fires.[4]

Technology

Traditionally solar-powered refrigerators and vaccine coolers use a combination of solar panels and lead batteries to store energy for cloudy days and at night in the absence of sunlight to keep their contents cool. These fridges are expensive and require heavy lead-acid batteries which tend to deteriorate, especially in hot climates, or are misused for other purposes.[3][4] In addition, the batteries require maintenance,[5] must be replaced approximately every three years, and must be disposed of as hazardous wastes possibly resulting in lead pollution.[3] These problems and the resulting higher costs have been an obstacle for the use of solar powered refrigerators in developing areas.[2][4]In the mid-1990s NASA JSC began work on a solar powered refrigerator that used phase change material rather than battery to store "thermal energy" rather than "chemical energy." The resulting technology has been commercialized and is being used for storing food products and vaccines.

Use

Solar-powered refrigerators and other solar appliances are commonly used by individuals living off-the-grid. They provide a means for keeping food safe and preserved while avoiding a connection to utility-provided power. Solar refrigerators are also used in cottages and camps as an alternative to absorption refrigerators, as they can be safely left running year-round. Other uses include being used to keep medical supplies at proper temperatures in remote locations, and being used to temporarily store game at hunting camps. [6]Passive solar building design

From Wikipedia, the free encyclopedia

| Part of a series about |

| Sustainable energy |

|---|

|

| Energy conservation |

| Renewable energy |

| Sustainable transport |

The key to design a passive solar building is to best take advantage of the local climate performing an accurate site analysis. Elements to be considered include window placement and size, and glazing type, thermal insulation, thermal mass, and shading.[2] Passive solar design techniques can be applied most easily to new buildings, but existing buildings can be adapted or "retrofitted".

Contents

- 1 Passive energy gain

- 2 As a science

- 3 The solar path in passive design

- 4 Passive solar heat transfer principles

- 5 Site specific considerations during design

- 6 Design elements for residential buildings in temperate climates

- 7 Efficiency and economics of passive solar heating

- 8 Key passive solar building design concepts

- 9 Landscaping and gardens

- 10 Other passive solar principles

- 11 Comparison to the Passive House standard in Europe

- 12 Design tools

- 13 Levels of application

- 14 See also

- 15 References

- 16 External links

Passive energy gain

Elements of passive solar design, shown in a direct gain application

Some passive systems use a small amount of conventional energy to control dampers, shutters, night insulation, and other devices that enhance solar energy collection, storage, and use, and reduce undesirable heat transfer.

Passive solar technologies include direct and indirect solar gain for space heating, solar water heating systems based on the thermosiphon, use of thermal mass and phase-change materials for slowing indoor air temperature swings, solar cookers, the solar chimney for enhancing natural ventilation, and earth sheltering.

More widely, passive solar technologies include the solar furnace and solar forge, but these typically require some external energy for aligning their concentrating mirrors or receivers, and historically have not proven to be practical or cost effective for widespread use. 'Low-grade' energy needs, such as space and water heating, have proven, over time, to be better applications for passive use of solar energy.

As a science

The scientific basis for passive solar building design has been developed from a combination of climatology, thermodynamics (particularly heat transfer: conduction (heat), convection, and electromagnetic radiation), fluid mechanics/natural convection (passive movement of air and water without the use of electricity, fans or pumps), and human thermal comfort based on heat index, psychrometrics and enthalpy control for buildings to be inhabited by humans or animals, sunrooms, solariums, and greenhouses for raising plants.Specific attention is divided into: the site, location and solar orientation of the building, local sun path, the prevailing level of insolation (latitude/sunshine/clouds/precipitation), design and construction quality/materials, placement/size/type of windows and walls, and incorporation of solar-energy-storing thermal mass with heat capacity.

While these considerations may be directed toward any building, achieving an ideal optimized cost/performance solution requires careful, holistic, system integration engineering of these scientific principles. Modern refinements through computer modeling (such as the comprehensive U.S. Department of Energy "Energy Plus"[3] building energy simulation software), and application of decades of lessons learned (since the 1970s energy crisis) can achieve significant energy savings and reduction of environmental damage, without sacrificing functionality or aesthetics.[4] In fact, passive-solar design features such as a greenhouse/sunroom/solarium can greatly enhance the livability, daylight, views, and value of a home, at a low cost per unit of space.

Much has been learned about passive solar building design since the 1970s energy crisis. Many unscientific, intuition-based expensive construction experiments have attempted and failed to achieve zero energy - the total elimination of heating-and-cooling energy bills.

Passive solar building construction may not be difficult or expensive (using off-the-shelf existing materials and technology), but the scientific passive solar building design is a non-trivial engineering effort that requires significant study of previous counter-intuitive lessons learned, and time to enter, evaluate, and iteratively refine the simulation input and output.

One of the most useful post-construction evaluation tools has been the use of thermography using digital thermal imaging cameras for a formal quantitative scientific energy audit. Thermal imaging can be used to document areas of poor thermal performance such as the negative thermal impact of roof-angled glass or a skylight on a cold winter night or hot summer day.

The scientific lessons learned over the last three decades have been captured in sophisticated comprehensive building energy simulation computer software systems (like U.S. DOE Energy Plus, et al.).

Scientific passive solar building design with quantitative cost benefit product optimization is not easy for a novice. The level of complexity has resulted in ongoing bad-architecture, and many intuition-based, unscientific construction experiments that disappoint their designers and waste a significant portion of their construction budget on inappropriate ideas.[citation needed]

The economic motivation for scientific design and engineering is significant. If it had been applied comprehensively to new building construction beginning in 1980 (based on 1970s lessons learned), America could be saving over $250,000,000 per year on expensive energy and related pollution today.[citation needed]

Since 1979, Passive Solar Building Design has been a critical element of achieving zero energy by educational institution experiments, and governments around the world, including the U.S. Department of Energy, and the energy research scientists that they have supported for decades. The cost effective proof of concept was established decades ago, but cultural assimilation into architecture, construction trades, and building-owner decision making has been very slow and difficult to change.[citation needed]

The new terms "Architectural Science" and "Architectural Technology" are being added to some schools of Architecture, with a future goal of teaching the above scientific and energy-engineering principles.[citation needed]

The solar path in passive design

Main articles: Sun path and Position of the Sun

The ability to achieve these goals simultaneously is fundamentally

dependent on the seasonal variations in the sun's path throughout the

day.This occurs as a result of the inclination of the Earth's axis of rotation in relation to its orbit. The sun path is unique for any given latitude.

In Northern Hemisphere non-tropical latitudes farther than 23.5 degrees from the equator:

- The sun will reach its highest point toward the south (in the direction of the equator)

- As winter solstice approaches, the angle at which the sun rises and sets progressively moves further toward the South and the daylight hours will become shorter

- The opposite is noted in summer where the sun will rise and set further toward the North and the daylight hours will lengthen[5]

In equatorial regions at less than 23.5 degrees, the position of the sun at solar noon will oscillate from north to south and back again during the year.[6]

In regions closer than 23.5 degrees from either north-or-south pole, during summer the sun will trace a complete circle in the sky without setting whilst it will never appear above the horizon six months later, during the height of winter.[7]

The 47-degree difference in the altitude of the sun at solar noon between winter and summer forms the basis of passive solar design. This information is combined with local climatic data (degree day) heating and cooling requirements to determine at what time of the year solar gain will be beneficial for thermal comfort, and when it should be blocked with shading. By strategic placement of items such as glazing and shading devices, the percent of solar gain entering a building can be controlled throughout the year.

One passive solar sun path design problem is that although the sun is in the same relative position six weeks before, and six weeks after, the solstice, due to "thermal lag" from the thermal mass of the Earth, the temperature and solar gain requirements are quite different before and after the summer or winter solstice. Movable shutters, shades, shade screens, or window quilts can accommodate day-to-day and hour-to-hour solar gain and insulation requirements.

Careful arrangement of rooms completes the passive solar design. A common recommendation for residential dwellings is to place living areas facing solar noon and sleeping quarters on the opposite side.[8] A heliodon is a traditional movable light device used by architects and designers to help model sun path effects. In modern times, 3D computer graphics can visually simulate this data, and calculate performance predictions.[4]

Passive solar heat transfer principles

Personal thermal comfort is a function of personal health factors (medical, psychological, sociological and situational), ambient air temperature, mean radiant temperature, air movement (wind chill, turbulence) and relative humidity (affecting human evaporative cooling). Heat transfer in buildings occurs through convection, conduction, and thermal radiation through roof, walls, floor and windows.[9]Convective heat transfer

Convective heat transfer can be beneficial or detrimental. Uncontrolled air infiltration from poor weatherization / weatherstripping / draft-proofing can contribute up to 40% of heat loss during winter;[10] however, strategic placement of operable windows or vents can enhance convection, cross-ventilation, and summer cooling when the outside air is of a comfortable temperature and relative humidity.[11] Filtered energy recovery ventilation systems may be useful to eliminate undesirable humidity, dust, pollen, and microorganisms in unfiltered ventilation air.Natural convection causing rising warm air and falling cooler air can result in an uneven stratification of heat. This may cause uncomfortable variations in temperature in the upper and lower conditioned space, serve as a method of venting hot air, or be designed in as a natural-convection air-flow loop for passive solar heat distribution and temperature equalization. Natural human cooling by perspiration and evaporation may be facilitated through natural or forced convective air movement by fans, but ceiling fans can disturb the stratified insulating air layers at the top of a room, and accelerate heat transfer from a hot attic, or through nearby windows. In addition, high relative humidity inhibits evaporative cooling by humans.

Radiative heat transfer

The main source of heat transfer is radiant energy, and the primary source is the sun. Solar radiation occurs predominantly through the roof and windows (but also through walls). Thermal radiation moves from a warmer surface to a cooler one. Roofs receive the majority of the solar radiation delivered to a house. A cool roof, or green roof in addition to a radiant barrier can help prevent your attic from becoming hotter than the peak summer outdoor air temperature[12] (see albedo, absorptivity, emissivity, and reflectivity).Windows are a ready and predictable site for thermal radiation.[13] Energy from radiation can move into a window in the day time, and out of the same window at night. Radiation uses photons to transmit electromagnetic waves through a vacuum, or translucent medium. Solar heat gain can be significant even on cold clear days. Solar heat gain through windows can be reduced by insulated glazing, shading, and orientation. Windows are particularly difficult to insulate compared to roof and walls. Convective heat transfer through and around window coverings also degrade its insulation properties.[13] When shading windows, external shading is more effective at reducing heat gain than internal window coverings.[13]

Western and eastern sun can provide warmth and lighting, but are vulnerable to overheating in summer if not shaded. In contrast, the low midday sun readily admits light and warmth during the winter, but can be easily shaded with appropriate length overhangs or angled louvres during summer and leaf bearing summer shade trees which shed their leaves in the fall. The amount of radiant heat received is related to the location latitude, altitude, cloud cover, and seasonal / hourly angle of incidence (see Sun path and Lambert's cosine law).

Another passive solar design principle is that thermal energy can be stored in certain building materials and released again when heat gain eases to stabilize diurnal (day/night) temperature variations. The complex interaction of thermodynamic principles can be counterintuitive for first-time designers. Precise computer modeling can help avoid costly construction experiments.

Site specific considerations during design

- Latitude, sun path, and insolation (sunshine)

- Seasonal variations in solar gain e.g. cooling or heating degree days, solar insolation, humidity

- Diurnal variations in temperature

- Micro-climate details related to breezes, humidity, vegetation and land contour

- Obstructions / Over-shadowing - to solar gain or local cross-winds

Design elements for residential buildings in temperate climates

- Placement of room-types, internal doors and walls, and equipment in the house.

- Orienting the building to face the equator (or a few degrees to the East to capture the morning sun)[8]

- Extending the building dimension along the east/west axis

- Adequately sizing windows to face the midday sun in the winter, and be shaded in the summer.

- Minimising windows on other sides, especially western windows[13]

- Erecting correctly sized, latitude-specific roof overhangs,[14] or shading elements (shrubbery, trees, trellises, fences, shutters, etc.)[15]

- Using the appropriate amount and type of insulation including radiant barriers and bulk insulation to minimise seasonal excessive heat gain or loss

- Using thermal mass to store excess solar energy during the winter day (which is then re-radiated during the night)[16]

Factors that can degrade thermal performance:

- Deviation from ideal orientation and north/south/east/west aspect ratio

- Excessive glass area ("over-glazing") resulting in overheating (also resulting in glare and fading of soft furnishings) and heat loss when ambient air temperatures fall

- Installing glazing where solar gain during the day and thermal losses during the night cannot be controlled easily e.g. West-facing, angled glazing, skylights[17]

- Thermal losses through non-insulated or unprotected glazing

- Lack of adequate shading during seasonal periods of high solar gain (especially on the West wall)

- Incorrect application of thermal mass to modulate daily temperature variations

- Open staircases leading to unequal distribution of warm air between upper and lower floors as warm air rises

- High building surface area to volume - Too many corners

- Inadequate weatherization leading to high air infiltration

- Lack of, or incorrectly installed, radiant barriers during the hot season. (See also cool roof and green roof)

- Insulation materials that are not matched to the main mode of heat transfer (e.g. undesirable convective/conductive/radiant heat transfer)

Efficiency and economics of passive solar heating

Darmstadt University of Technology in Germany won the 2007 Solar Decathlon in Washington, D.C. with this passive house designed specifically for the humid and hot subtropical climate.[18]

Passive solar fraction (PSF) is the percentage of the required heat load met by PSH and hence represents potential reduction in heating costs. RETScreen International has reported a PSF of 20-50%. Within the field of sustainability, energy conservation even of the order of 15% is considered substantial.

Other sources report the following PSFs:

- 5-25% for modest systems

- 40% for "highly optimized" systems

- Up to 75% for "very intense" systems

For more information see Solar Air Heat